19

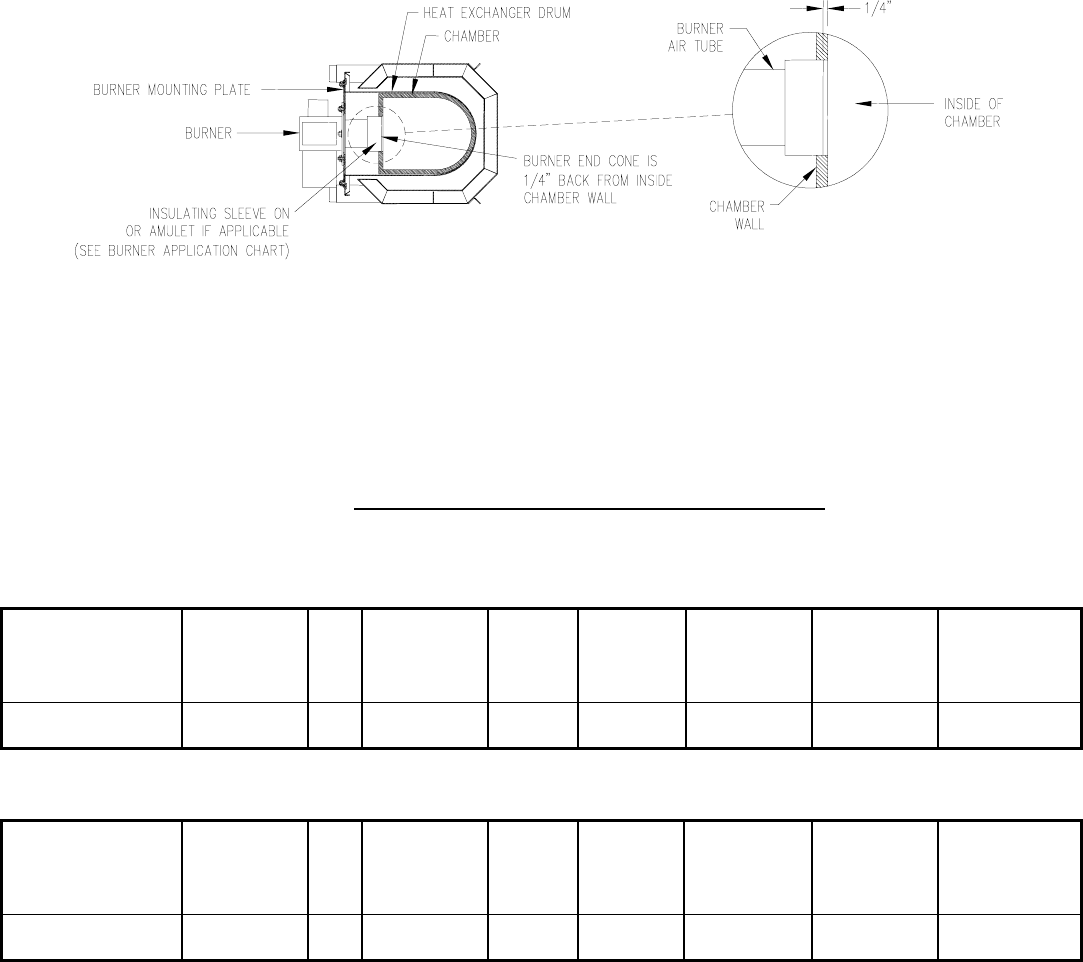

Fig. 13: Burner insertion illustration (Top view)

When mounting the burner, the mounting plate (Fig. 12) must be removed to provide access to the area

in front of the combustion chamber. A fiber insulating sleeve or amulet is provided on the burner tube of

specific Thermo Pride burners.(see Fig. 13). See Thermo Pride burner application chart for type of

insulator. Do not allow the burner tube or end cone to physically touch or protrude into the chamber, as

excess heat transfer could result in destruction of the tube, end cone or both. The burner tube/end cone is

properly positioned, when the end is ¼ inch back from the inside surface of the combustion chamber wall.

For horizontal applications, the mounting plate and chamber retainer will need be rotated 90º left or right,

depending on furnace position. DO NOT CHANGE POSITION OF THE CHAMBER!

H. BURNER SPECIFICATIONS AND APPLICATIONS:

FURNACE MODEL

THERMO

PRIDE’S

BURNER

SPEC NO.

*

INS

BECKETT

BURNER

MODEL &

TUBE

LENGTH

HEAD STATIC

PLATE

MAXIMUM

NOZZLE

SIZE**

SHIPPED

NOZZLE SIZE

OIL

PUMP

PRESSURE

(PSIG)

OD6**072D**B TP2501 N AFG-4.5” F3 3-5/8

0.75X80° H 0.60X80° H

120

The optional BF3 Riello flame retention oil burner can be used with OH6.

FURNACE MODEL

THERMO

PRIDE’S

BURNER

SPEC NO.

*

INS

RIELLO

BURNER

MODEL &

TUBE

LENGTH

HEAD STATIC

PLATE

MAXIMUM

NOZZLE

SIZE**

SHIPPED

NOZZLE SIZE

OIL

PUMP

PRESSURE

(PSIG)

OD6**072D**R C8511325 S BF3-4.5” N/A N/A

0.70X80° H 0.60X80° H

140

Table 6: Beckett & Riello burners specifications

* INSULATOR S = SLEEVE OR N = NONE

THE NOZZLE SIZE GIVES THE NOMINAL FLOWRATE, IN GPH, FOLLOWED BY THE SPRAY

ANGLE, IN DEGREE’S, AND THE SPRAY PATTERN, EITHER “H” FOR HOLLOW CONE OR “S”

FOR SOLID CONE. FOR EXAMPLE, A NOZZLE RATED AT 0.65 GPH @ 100 PSIG THAT PROVIDES

AN 80° SPRAY ANGLE AND A HOLLOW SPRAY PATTERN WOULD BE ABBREVIATED IN THE

TABLE AS “0.65 X 80°H”.

For more specific burner information, contact:

Thermo Products, LLC. P.O. Box 217, North Judson, IN 46366.

Phone 574-896-2133.