13

The ASHRAE Handbook – Fundamentals is an excellent source of duct system design principles

and pressure drop data. Conversely, for a specified type of fitting, it is also possible to determine

the required size or diameter of the component for a specified pressure drop and flowrate.

h. The resistance of the take-off and the outlet register (or return grill) should then be summed

together to determine the total pressure drop for each branch. This value should be close to

the assumed value for the pressure drop of the system. If it is not close, then flowrates for

each branch must be adjusted, or the design of the duct system must be altered, to give the

proper pressure drops. Usually, the cross-sectional area of the ductwork should be changed

in order to adjust the pressure drop to a suitable value. Refer to Example 2, (page 14) for a

sample calculation of how to use this method for sizing the supply side ductwork for a

residence.

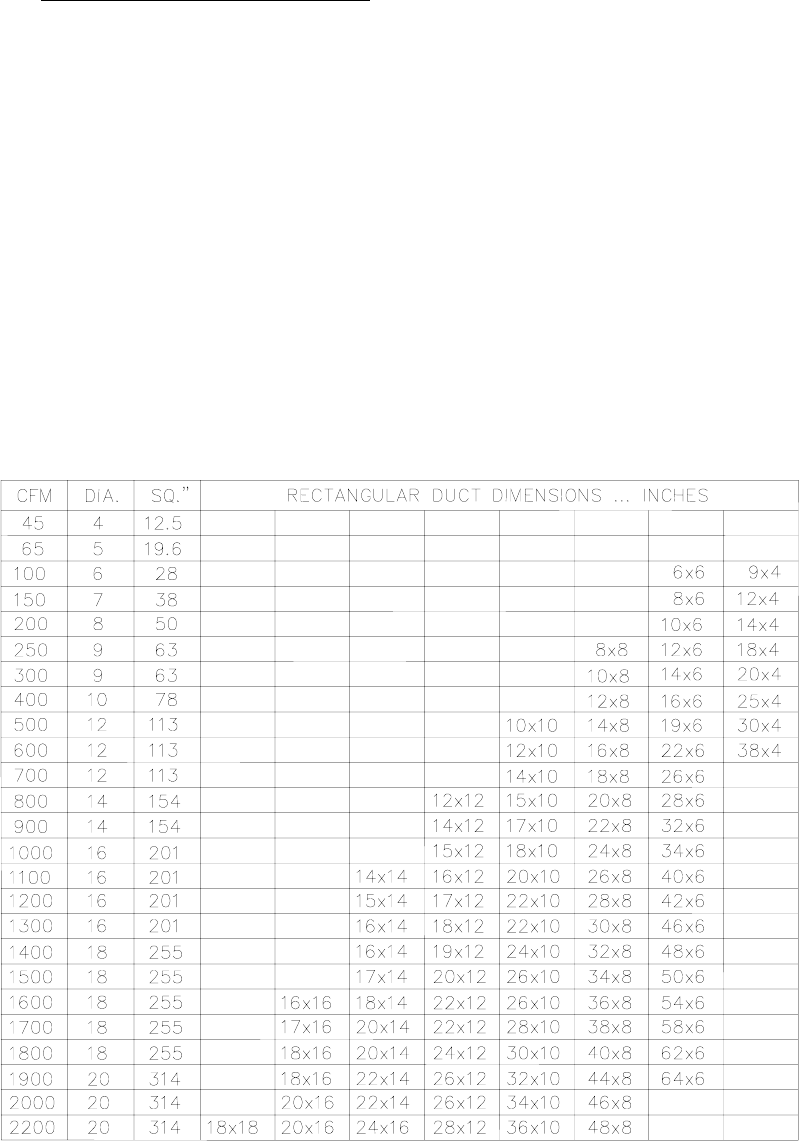

Table 3 shows the air handling capacities of 100-ft. lengths of circular and rectangular

ductwork based on a 0.1 in. W.G. static pressure drop. The first column to the right is the air

flowrate and the second is the required diameter for a circular duct. The third column is the

required cross-sectional area of the duct and the other columns to the left are rectangular

ducts with sufficient cross-sectional area to handle the flow at the specified pressure drop.

[For lengths of ductwork less than 100 ft., simply multiply 0.1 in. W.G. by the ratio of the

actual duct length (in feet) over 100 ft. for the approximate pressure drop.] Use the supplier’s

catalog for proper sizing of outlet air registers and return air grills to insure that they provide

the required flowrate at the desired pressure drop.

Table 3: Suggested Duct Sizes for Homes, Quiet Offices, Or Similar Installations

(Based on a 0.1 in. W.G. static pressure drop per 100 ft. of duct.)

7. The supply and return air ducts, or flexible joints, should be carefully secured and sealed to the

appliance housing to prevent air leakage from, or into, the duct system. For best performance,

insulate the outside surfaces of the ducts to reduce heat loss from, or heat gain to, the ducts.