7

TDVDSN Series Direct Vent Gas Fireplace

20007890

A hearth is not mandatory but is recommended for

aesthetic purposes. We recommend a noncombustible

hearth which projects out 12” (305 mm) or more from

the front of the fireplace.

Cold climate installation recommendation:

When installing this unit against a non-

insulated exterior wall or chase, it is

mandatory that the outer walls be insulated

to conform to applicable insulation codes.

NOTE: Never allow vapor barrier to contact the

outer casing of this fireplace or venting.

Hearth

Noncombustible materials such as brick or tile may be

extended over the edges of the face of the appliance.

DO NOT cover any vent or grille panels.

If a Trim Kit is going to be installed on the fireplace, the

brick or tile will have to be installed flush with the edges

of the appliance.

Final Finishing

Framing and Finishing

1. Choose the unit location.

2. Place the unit into position and secure it to the floor

with 1¹⁄₂” (38 mm) screws, or nails. The holes to

secure the unit to the floor are located just behind

the access door grille on the left and right side of the

unit.

3. Frame in the fireplace with a header across the top.

It is important to allow for the finished wall face when

setting the depth of the frame.

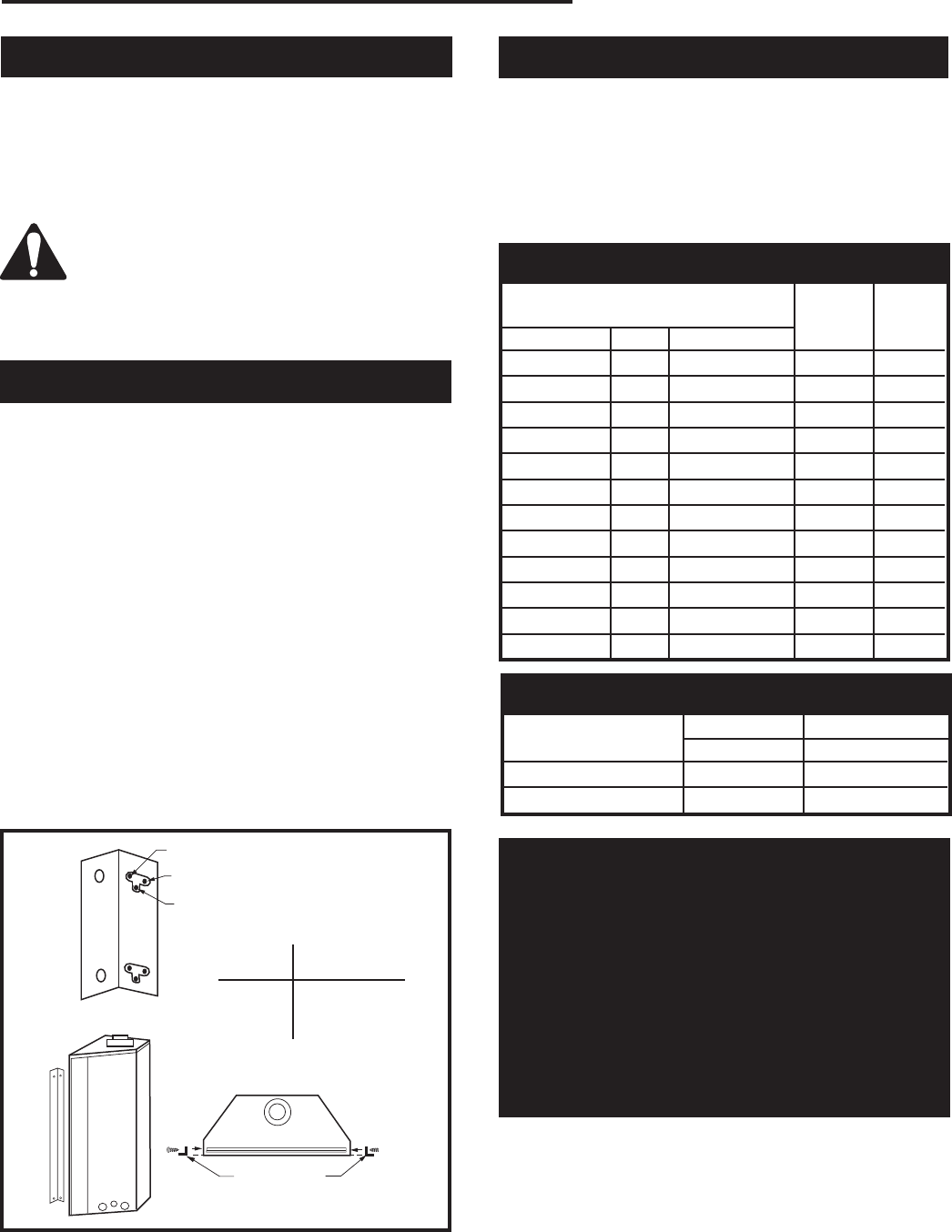

4. Attach the fireplace to the frame using the adjust

-

able frame drywall strips (located behind the access

door for shipping). Preset the depth to suit the facing

material of the wall. The strips are adjustable to 1/2”

(13 mm), 5/8” (16 mm) or 3/4” (19 mm). (Fig. 4)

5. Screw through the slotted holes in the drywall strip

and into the pre-drilled holes in the fireplace side.

Measure from the face of the fireplace to the face of

the drywall strip to confirm the final depth.

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the cur-

rent ANSI Z223.1/NFPA 54 and/or local codes hav-

ing jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

Natural LP (Propane)

Inlet Minimum 4.5” w.c. 10.8” w.c.

Inlet Maximum 14.0” w.c. 14.0” w.c.

Manifold Pressure 3.5” w.c. 10.0” w.c.

Gas Inlet and Manifold Pressures

FP1023

side nailing flange

1/27/00 djt

C

A

B

Fig. 4 Nailing flanges.

FP1023

Adjustable

1/2”, 5/8” &

3/4” Spacing

Adjustable Drywall Strip

(Nailing Flange)

Screw Drywall

Position Depths

A 1/2” / 13 mm

B 5/8” / 16 mm

C 3/4” / 19 mm

Gas Specifications

Max. Min.

Input Input

Model Fuel Gas Control BTU/h BTU/h

33TDVN Nat Millivolt 18,000 12,500

33TDVP Prop Millivolt 18,000 12,500

33TDVDSN Nat 120 V 18,000 n/a

33TDVDSP Prop 120 V 18,000 n/a

36TDVN Nat Millivolt 20,000 13,000

36TDVP Prop Millivolt 20,000 13,000

36TDVDSN Nat 120 V 20,000 n/a

36TDVDSP Prop 120 V 20,000 n/a

39TDVN Nat Millivolt 22,000 15,000

39TDVP Prop Millivolt 22,000 16,000

39TDVDSN Nat 120 V 22,000 n/a

39TDVDSP Prop 120 V 22,000 n/a