NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

9

Step 2. Align the canopy with the holes in the

top frame.

Step 3. Replace the screws previously removed.

Step 4. Tighten side screws. Make sure the

canopy is level and secure.

OPTIONAL EQUIPMENT

Blower Kit

Circulating Models Only

If you are installing one of the blower kits,

Models FBK-100 or FBK 200, follow Steps 1

through 5, and see the installation instructions

provided with the kit for electrical wiring re-

quirements (

see Figure 11 )

. The firebox must

be connected to main power supply at time of

installation if a forced air kit is to be installed

later. The electrical connections must be made

before the firebox is framed and enclosed in the

finished walls.

This appliance must be electrically grounded in

accordance with local codes or, in the absence

of local codes, the national electrical code,

ANSI/NFPA 70 - (Latest Edition).

CAUTION: ELECTRICAL CONNECTIONS

SHOULD ONLY BE PERFORMED BY A QUALI-

FIED, LICENSED ELECTRICIAN. MAIN POWER

MUST BE OFF WHEN CONNECTING TO MAIN

ELECTRICAL POWER SUPPLY OR PERFORM-

ING SERVICE.

Note: The nailing flange and the area directly

behind the nailing flange is exempt from the

clearances described on the firebox clearance

label.

Step 5. To safely operate the heater with con-

sideration of the mantel clearances the canopy

must be installed.

Canopy Installation

The factory-supplied canopy must be installed

on the firebox for safe operation. See

Figure 10

.

8d Nail

Figure 9

Grounded

to Appliance

Blower Motor

Motor Plug

Receptacle

120V

Appliance Junction Box

NOTE: If any of the original wire as supplied

must be replaced, it must be replaced with type

AWM 105°c – 18Ga. wire

Figure 11

Figure 10

Attaching

Screws

UVF-500

Shown

UVF-500

Canopies

Firebox

Opening

UVF-600

Canopies

3 Screws for 500 Models

4 Screws for 600 Models

Firebox

Opening

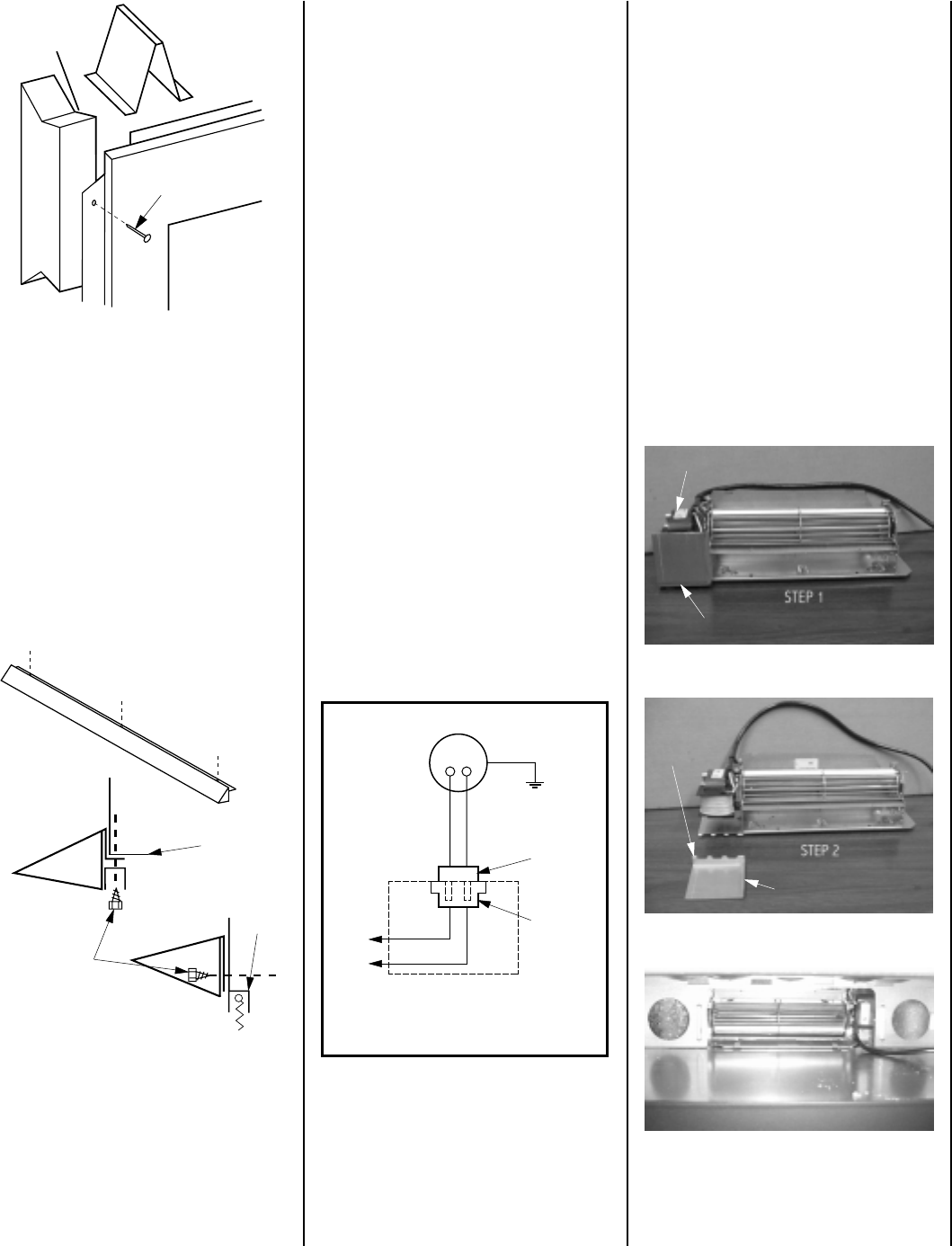

Blower Kit Installation

To install the blower kit, follow Steps 1 thru 5

and refer to

Figures 12, 13 and 14

.

Step 1. Locate the blower motor shield.

Step 2. Remove the motor shield by bending it

along the perforation until the tabs break away.

Step 3. With the motor shield removed, place

the blower in the unit with the power cord up

and slide to the back of the unit until the motor

is behind the rear support.

Step 4. Rotate the blower 90 degrees, so that

the discharge is up.

Step 5. Move left side of blower around until it

is in the proper position and bend the retaining

tabs in the bottom of the unit up into the slots

on the blower.

Figure 12

Figure 13

Blower Motor

Motor Shield

Perforation

Tabs

Motor Shield Removed

Step 1. Remove the screws from the top front

frame assembly. There are three (3) screws on

the 500 models and four (4) screws on the 600

models.

Figure 14

Rotated Blower In Final Position