Cabinet Series Dehumidifying Dryer 48

Chapter 7: Troubleshooting

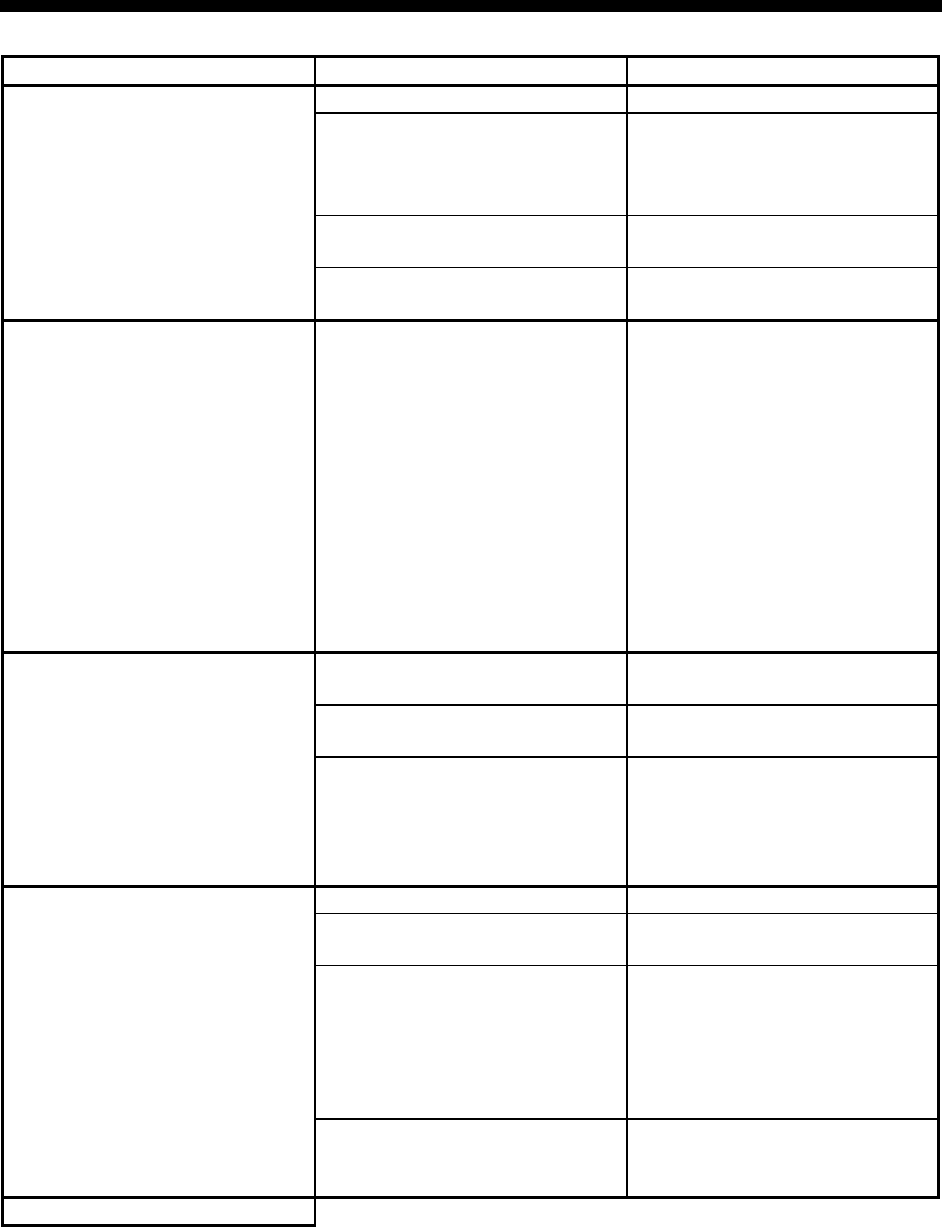

Problem Possible cause Corrective action

Dirty filter. Clean or replace filter.

Desiccant beds are

contaminated by material or

plasticizer leaking into the

system.

Replace desiccant.

Blower overload has tripped.

Fix the problem and reset the

overload.

Little or no air coming from

the process delivery tube.

Blower fins filled with dust or

contaminants.

Remove blower side plate,

clean baffles, replace.

Suction in delivery tube,

pressure from the return

tube.

Phase is reversed on power

drop coming into the dryer.

Stop the dryer.

If the dryer was connected to

the drying hopper, check to

see if the desiccant and

process air heater has been

contaminated with resin.

If so, replace the desiccant

and remove any resin carry-

over. Otherwise, change the

phase of two legs of the

three-phase power drop.

Process heaters are faulty.

Check for open heaters.

Replace if required.

Solid-state temperature

controller faulty.

Replace.

Loss or reduction of process

air temperature.

Process temperature was

adjusted in error by plant

personnel.

Make sure that plant

personnel are aware of the

proper temperature set point.

A sign posted next to the

controller is helpful.

Process heaters are faulty. Replace.

Desiccant beds are

contaminated.

Replace desiccant.

Material being dried differs

from material specified at the

time of purchase.

Drying systems are designed

for the material which was

originally specified. Different

materials may need a longer

residence time or different

drying temperature.

Loss or reduction in drying

capacity.

Break in flex hose to/from

drying hopper.

Inspect for air leaks; replace

if necessary.