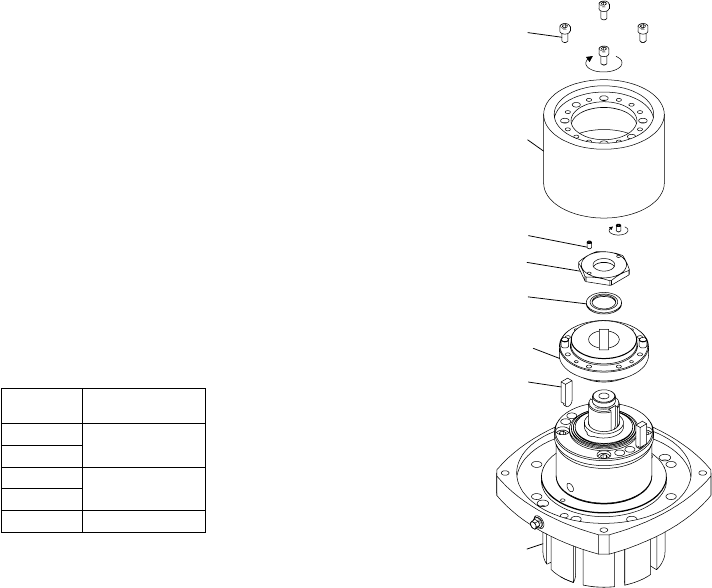

58

8490

8310

8520

8510

8500

8350-D

8400

0701

8350-B

A.0500.551 – IM-TGMAG/02.00 EN (02/2008)

6. Fit the keys (8400) into the rotor shaft (0701). Be care-

ful that the keys (8400) are not hitting the shaft sleeve

(8350-B) during assembly.

7. Fit rear axial bearing holder (8350-D) on the rotor shaft

(0701).

8. Place spring washer (8500) on the rotor shaft (0701) as

indicated on the sketch and screw on locking nut (8510).

9. Place the assembly vertically on the work bench and lock

the rotor by pushing a copper bar through the rotor teeth.

10. Tighten locking nut (8510) until the shaft nut makes

contact with the axial face of the rear axial bearing holder

(8350-D).

11. Check the axial bearing clearance using a feeler gauge

(see table below).

TG MAG

Axial clearance

[mm]

15-50

0.11 – 0.13

23-65

58-80

0.13 – 0.15

86-100

185-125 0.15 – 0.18

12. Tighten set screws (8520) to secure the locking nut

(8510).

13. Mount the inner magnetic rotor (8310) on the hub of the

rear axial bearing holder (8350-D). Make sure that the

locking pins are falling into the holes of the inner magnetic

rotor (8310).

14. Screw in cap head screws (8490) and tighten them (with

Loctite 243) crosswise with the specified torque (see

Chapter 3.21.3.1) to fix the inner magnetic rotor (8310)

on the hub.

15. Check if the rotor shaft (0701) can be turned by hand

evenly and without remarkable resistance.