28

wire.

3. Insert grease fittings in grease fill openings and add grease until grease

is forced out through relief openings.

4. Replace fill plugs and operate mechanical equipment 30 minutes to

one hour to purge excess grease at grease relief opening.

5. Reinstall grease relief plugs and reinstall guard.

6. Resume normal fluid cooler operation.

Seasonal Shutdown Instructions

When the system is to be shut down for an extended period of time, it is

recommended that the recirculation water system be drained. Leave the

basin drains open.

Draining the coil is not recommended—draining promotes corro-

sion inside the coil tubes. See protecting coil in Freezing weather

on page 18.

During shutdown, clean the fluid cooler (see Warning, page 21) and make

any necessary repairs. Eliminators and louvers are easily removed to gain

access to the coil. Pay particular attention to mechanical equipment sup-

ports and sheaves or coupling (or drive shafts).

Following each year’s shutdown and cleaning, inspect the fluid cooler’s

metal surfaces for evidence of the need to apply a protective coating. Do

not misinterpret grime as a need to have the tower painted. If relatively

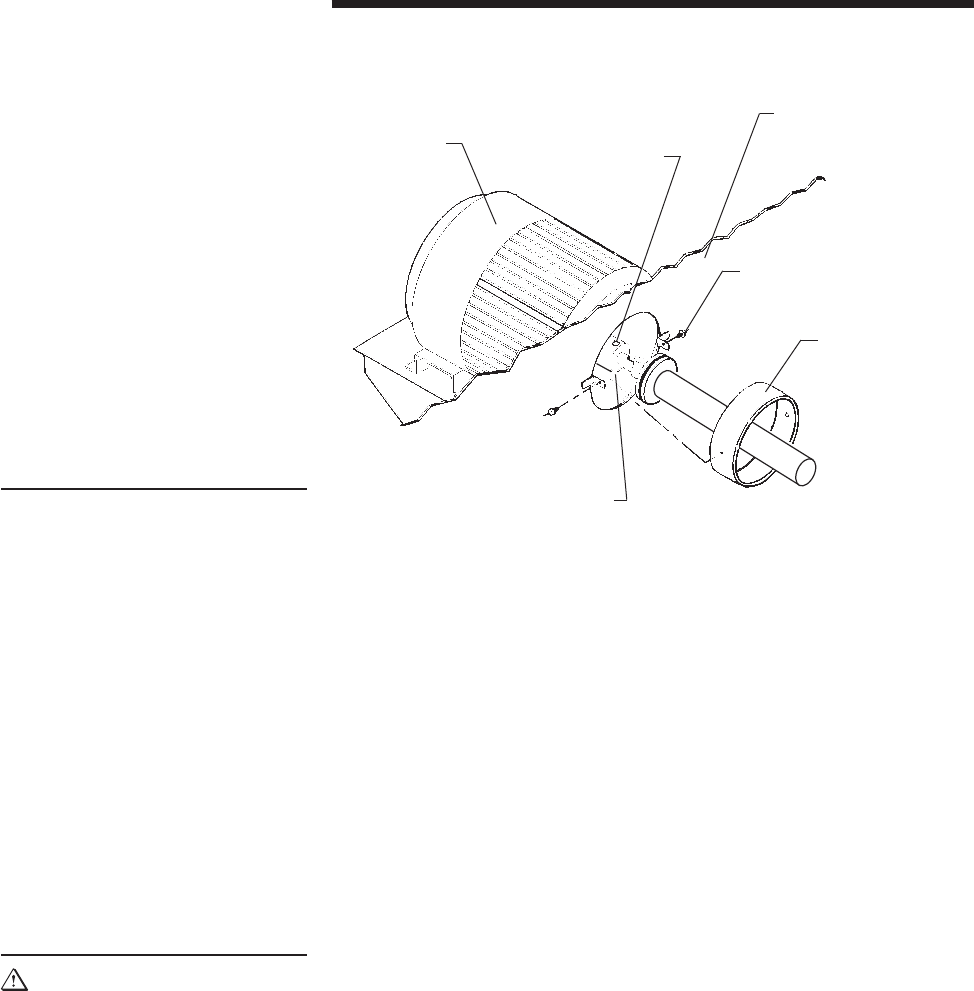

Motor

Guard

Steel Side Casing

Attachment Screw

Grease Relief Plug

Grease Fill Plug

Figure 4

Caution

Maintenance