Combining over 80 Years of Cooling Tower Experience

With over 50 Years of Fiberglass Experience

Marley began using composites

in cooling towers in the early

1950s, when they were considered

“exotic materials”. In fact, Marley’s

work with what was then called

GRP (glass-reinforced polyester)

was so extensive that we were

issued a registered trademark

for GRP in 1960. Since then,

commercial formulations have been generically known as FRP

(fiber-reinforced polyester).

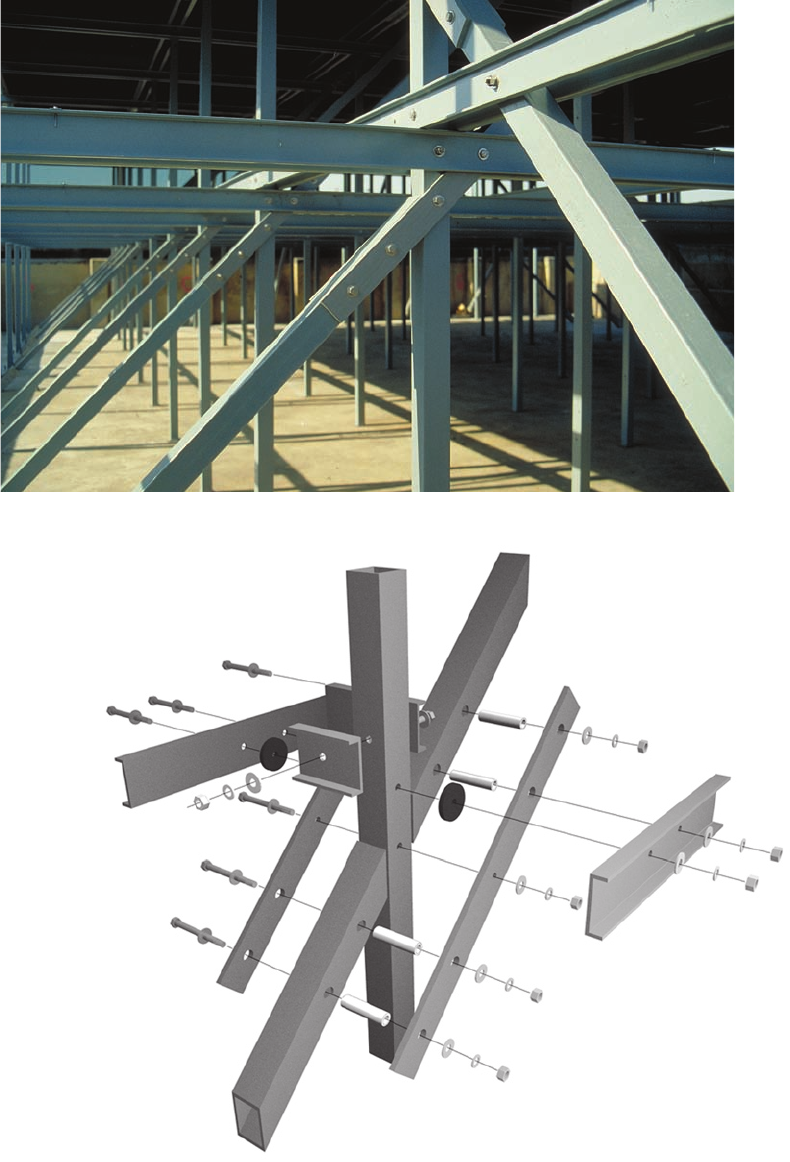

Through a process called pultrusion, fiberglass components

can be produced to even higher standards. Components

in the F400 cooling tower meet the stringent

Marley requirements for consistent strength and

predictable performance.

Pultruded structural components are used

throughout the F400 cooling tower to produce an

engineered framework of unsurpassed quality, reliability and

safety. And, the F400’s structural components will always

be available for simple, economic repairs.