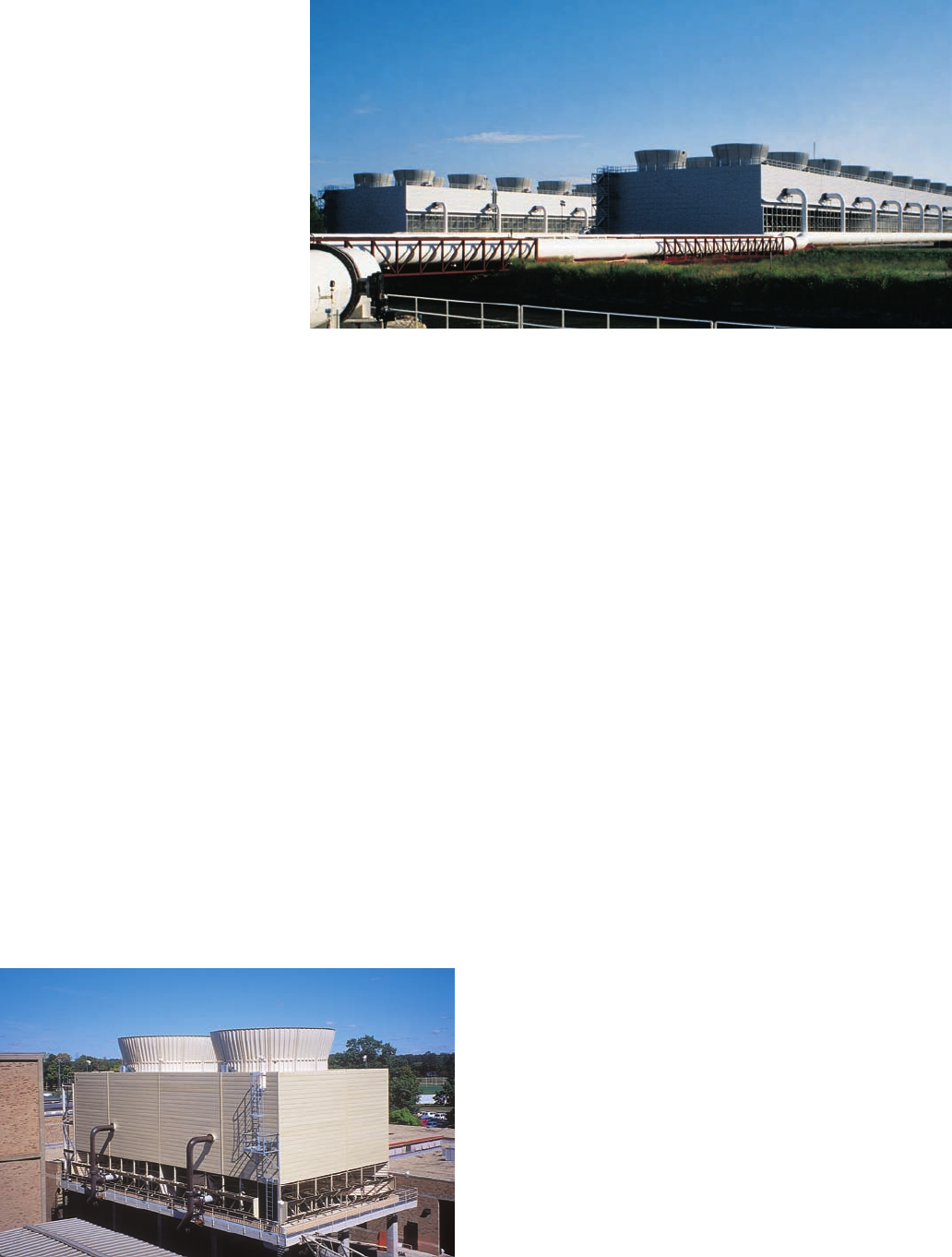

Proven Design

Improved Structural Materials

The Marley industrial counterflow cooling tower has proven

itself as one of the most efficient and reliable designs ever. The

F400 cooling tower is a logical engineered evolution of this

proven design, making use of pultruded fiberglass shapes as

structural members.

Proven through years of successful chemical plant

construction, pultruded fiberglass is ideal for the wet, corrosive

cooling tower environment. It’s strong like steel but at a fraction

of the weight. Yet, it will not corrode from chemical exposure or

moisture, and it resists deterioration from sunlight.

Design Integrity

The F400 cooling tower elevates the proven Marley

structural design to an even higher level of dependability and

performance.

■ Theory Equals Performance

The engineering properties of Marley fiberglass structural

members are predictable and consistent. Laboratory testing

verifies the structural designs before their application in cooling

towers.

■ Quality Structural Connections

Bolted, non-glued design provides the highest reliability under

the most adverse conditions. Stainless steel fasteners are used

throughout the F400 in conjunction with bearing sleeves to

minimize fiberglass shear stress in the bolted joints.

■ Permanent Structural Stability

Marley structural designs reflect the actual conditions of heat,

moisture and dynamic loading encountered in cooling towers.

These structures are up to the task!