6

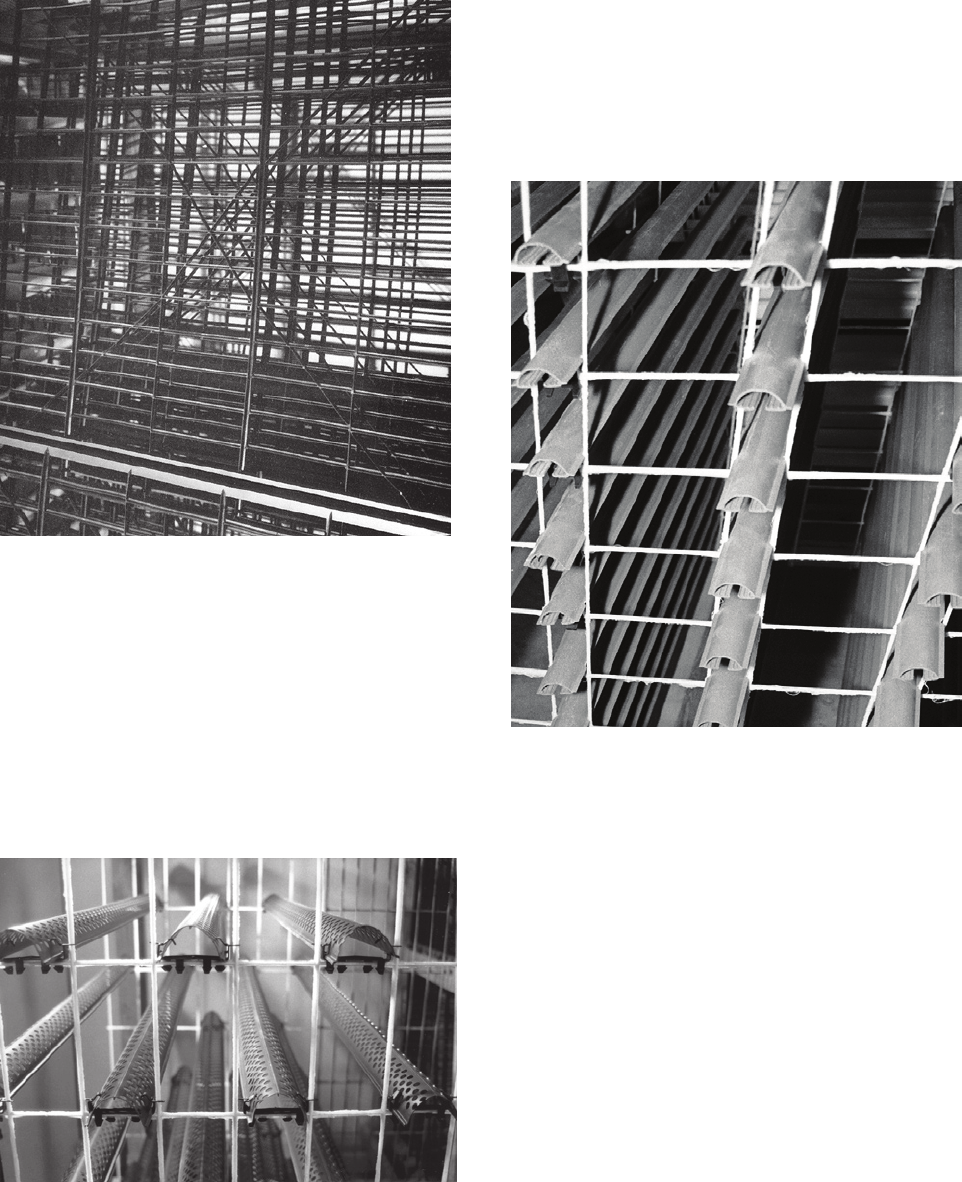

Class 600 splash fill bars are available in the following

materials:

• PVCin“Omega”,“Mega”or“Alpha”

configurations.

• Injection-moldedpolypropylene“Ladder”

configurations.

• Roughsawn,preservative-treatedwood

“G” configurations.

Each cooling tower application is individually reviewed

to assure selection of the proper fill type and fill spacing.

Performance is computer optimized to assure maximum

cooling from a given tower cell size for the design

performance conditions.

Long functional life for cooling tower fill depends on

the splash bar support. Wood lath and PVC splash bars

are supported in FRP grids. Chemically, the resistance

of FRP to acids, alkalis, salts, and oils is rated excellent

through concentrations much higher than could ever

occur in a cooling tower. Mechanically, the FRP support

system takes advantage of tensile strength exceeding

30,000 psi. FRP exhibits very little creep under stress of

live and dead loads throughout the extremes of moisture

and temperature variations.

/ Fill /