10

/ Casing /

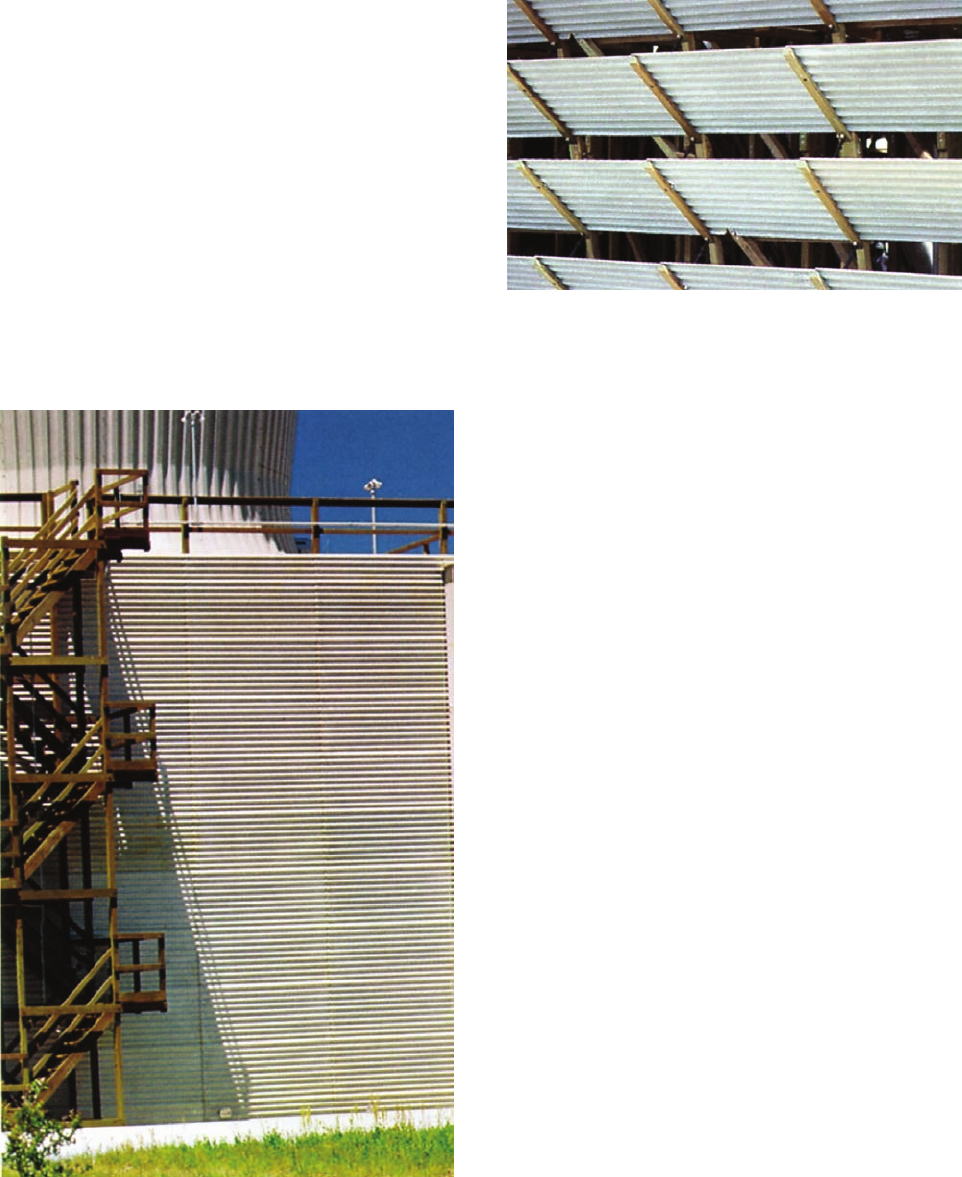

The endwalls of Class 600 towers are cased from the

fan deck level to below the top of the basin curb with

8 oz/sq ft corrugated FRP sheets. FRP is waterproof and

corrosion proof, is immune to biological deterioration,

and requires no maintenance. Sheets are installed

on maximum 4′-0″ spans with corrugations running

horizontally. Vertical joints are lapped and sealed.

Horizontal joints are lapped one corrugation to shed water

inward. The casing is attached to structural members

with stainless steel screw shank fasteners, complete with

neoprene bonded washers. Corner trim pieces are 12

oz/sq ft molded FRP.

/ Louvers /

42″ wide louver blades, made of 9 oz/sq ft corrugated

FRP, prevent splash out. Exterior grade plywood louvers

are used in freezing climates. Continuous 2″ x 4″

members beneath the louvers provide bearing across the

entire louver width. These supports are rigidly framed into

louver posts by through bolting at the bottom and are tied

near the top by molded structural polypropylene tie bars.

Louvers are supported on 4′-0″ centers by 4″ x 4″

structural columns. This scheme provides more than

twice the bending strength compared to designs utilizing

6′-0″ spans.

The relationship between the louvers and the direction

of water flow results in a uniform, light water cascade

down the inboard edge of the louvers. This cascade

protects the fill from ice formation and possible damage.

Standard FRP louvers are positioned on 4′-0″ vertical

centers. Plywood louvers used in freezing climates

are positioned on 3′-0″ vertical centers. This spacing

eliminates stagnant areas in the fill, thereby reducing the

tendency for fine moisture particles to form sheet ice,

plugging air inlets.