7

/ Construction And Components /

■ Mechanical Equipment

Belt-driven propeller fans insure design airflow at minimum

horsepower. Fans are supported by an oil-lubricated tapered

roller bearing assembly with remote oil reservoir.

For ease of maintenance all drive components are

accessible from outside the tower.

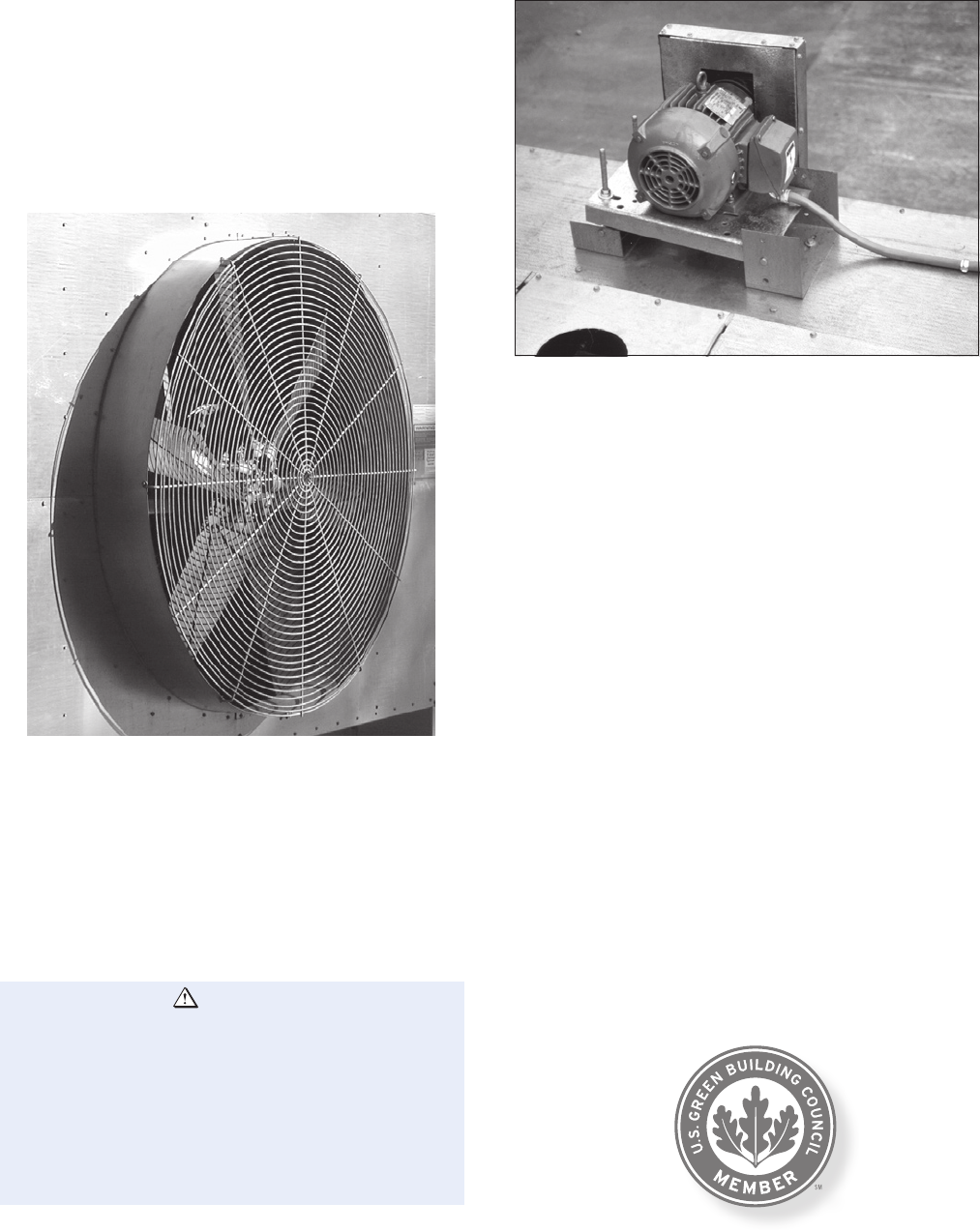

Fan and fan guard. Guard is easily removed for access to

fan and drive belts

Fan drive motor showing adjustable base and belt guard

■ Hoisting and Handling

Hoisting instructions on each tower explains how to use

a spreader-bar and slings beneath the cold water basin floor

to hoist the Aquatower. The tower’s design also allows easy

handling with a forklift.

■ Safety

Standard Aquatower safety features include fan guards and

belt guards. Fan guards consist of welded heavy gauge steel

wire hoops and spokes, hot dip galvanized after fabrication.

The galvanized steel belt guard encloses both belts and

pulleys. Guards are easily removed for servicing.

■ Construction and Finish

Aquatowers offer the corrosion protection of G-235

galvanized—providing a zinc thickness of 2.35 oz/ft

2

per ASTM

A-653—providing long term protection for the steel. Assembly

hardware is also galvanized.

Caution

The cooling tower must be located at such distance and

direction to avoid the possibility of contaminated tower

discharge air being drawn into building fresh air intake

ducts. The purchaser should obtain the services of a

Licensed Professional Engineer or Registered Architect

to certify that the location of the tower is in compliance

with applicable air pollution, re, and clean air codes.

Fan drive motors are TEFC (may be TENV on model 490A)

designed specifically for cooling tower use. Horsepowers and

electrical characteristics appear in the table on page 4. Other

types of motors are available. Typical options appear under

Optional Accessories on page 10.