6

/ Construction And Components /

■ Water Distribution System

Warm water flows through external piping (not included

with the tower) into a splash box chamber at the top of the

Aquatower. A splash box prevents the incoming water from

spilling out of the basin and helps provide uniform water

distribution. Water then flows by gravity from the basin through

nozzles to the fill.

■ Fill/Louvers/Drift Eliminators

Fill sheets include integral louvers and drift eliminators,

designed to minimize resistance to airflow. This patented

arrangement prevents water from escaping the fill sheets,

assuring proper heat transfer throughout wide variations in

airflow. Users find this fill operates ice-free even in extremely

cold weather.

The thermoformed 15 mil (.015″) thick PVC fill sheets

withstand hot water temperatures as high as 125°F. Fill sheets

are immune to biological and corrosive decay and their flame

spread rating is less than 25 per ASTM E-84. Galvanized

structural tubes support and stabilize the fill. They also hold

the bottom of the fill sheets above the cold water basin floor to

simplify basin cleaning. Removable 1″ x 1″ mesh galvanized

air inlet screens keep larger airborne trash out of the collection

basin and fill area.

Hot water distribution basin covers are provided as

standard equipment to keep the distribution basin free from

airborne debris and to reduce the likelihood of biological

growth.

All Aquatowers use Marley “Spiral Target” nozzles. These

inert polypropylene nozzles are evenly spaced thoughout the

distribution basin to assure uniform water distribution over

all portions of the fill. Their large openings resist clogging.

Nozzles are easy to remove and replace if you ever want to

change the design water flow rate.

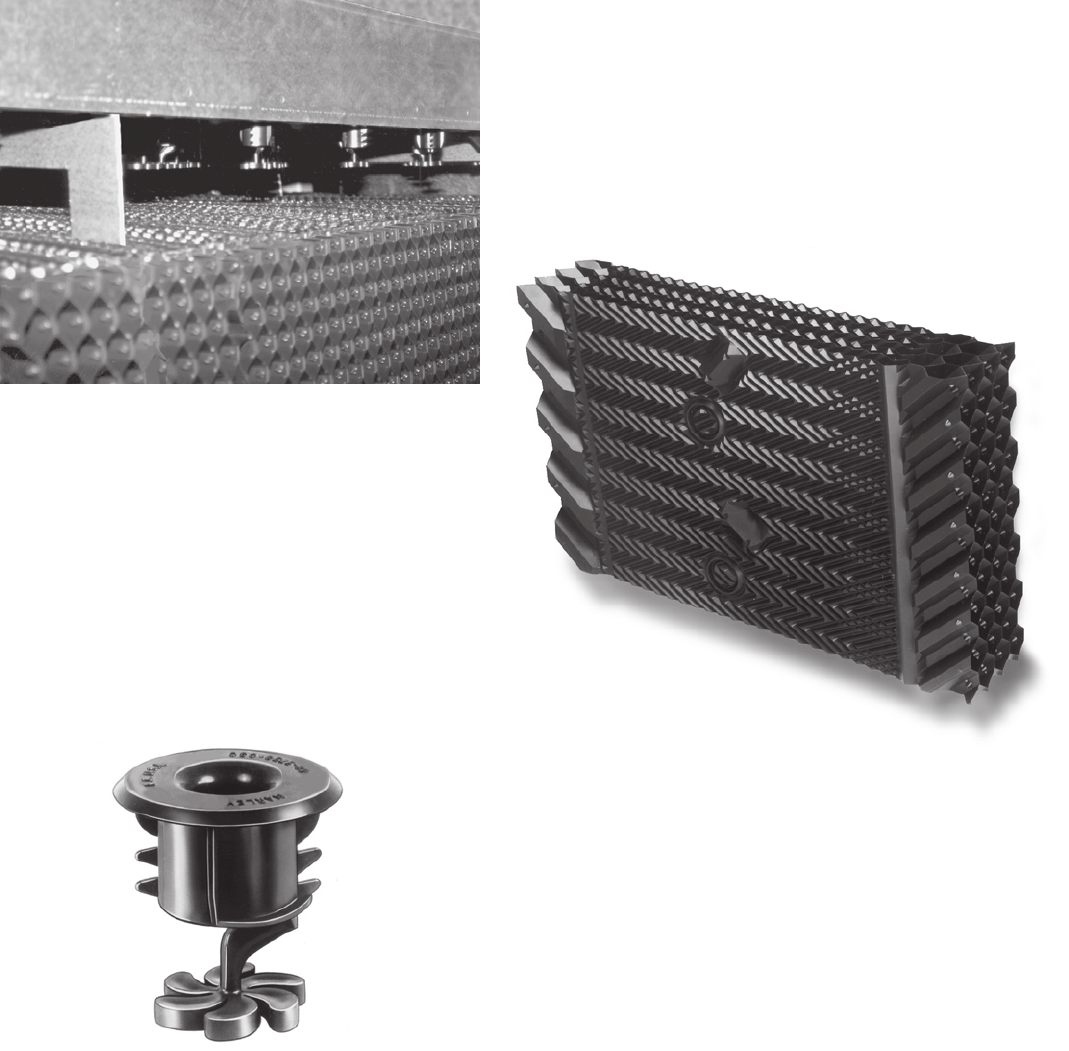

Eliminator air-seal removed showing distribution area above fill

Spiral-target distribution nozzle

MX Fill

■ Cold Water Collection Basin

The Aquatower’s collection basin reduces operating

weight, simplifies basin cleaning, and assures proper outflow.

Water flows from the elevated area under the fill into the basin’s

rear depressed section, where side suction piping connects. A

bottom outlet is also available for gravity flow applications.

Standard equipment on each tower basin includes: a

screened suction connection; a threaded overflow connection;

a threaded and plugged drain connection; and a float-operated

make-up valve. Models 492A through 496B also include a

bottom outlet conforming to 125# flange specification. A blank

cover plate is provided to seal the outlet connection not used.