23

Maintenance

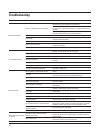

Schedule of Tower Maintenance

Some maintenance procedures may require maintenance personnel to enter

the tower. Each cased face of the tower has a door for access to the interior

of the tower. All AV Series have a 30″ wide by 42″ high door opening.

The purchaser or owner is responsible for providing a safe method

forenteringorexitingtheaccessdoor.Protectiveclothingtoavoid

cuts from sheet metal should be worn. Wet sheet metal an/or dirt can

be slippery. Nonslip sole shoes should also be worn.

Included with this instruction packet are separate User Manuals on each

major operating component of the tower, and it is recommended that you

read them thoroughly. Where discrepancies may exist, the separate User

Manuals will take precedence.

The following is recommended as a minimum routine of scheduled main-

tenance:

Always shut off electrical power to the tower fan motor prior to

performing any inspections that may involve physical contact with

themechanicalorelectricalequipmentinoronthetower.Lockout

and tag out any electrical switches to prevent others from turning

thepowerbackon.Servicepersonnelmustwearproperpersonal

protectiveclothingandequipment.

Weekly: Inspect for bacterial growth and general operation conditions.

Bacterial growth should be reported to your water treatment expert for

immediate attention.

Monthly (Weekly at start up): Observe, touch, and listen to the tower.

Become accustomed to its normal appearance, sound, and level of vi-

bration. Abnormal aspects relating to the rotating equipment should be

considered reason to shut down the tower until the problem can be located

and corrected. Observe operation of the motor, sheaves, belt, and fan.

Become familiar with the normal operating temperature of the motor, as

well as the sight and sound of all components as a whole.

Inspect louvers, drift eliminators and basin trash screens and remove any

debris or scale which may have accumulated. Replace any damaged

Warning

➠