3

3

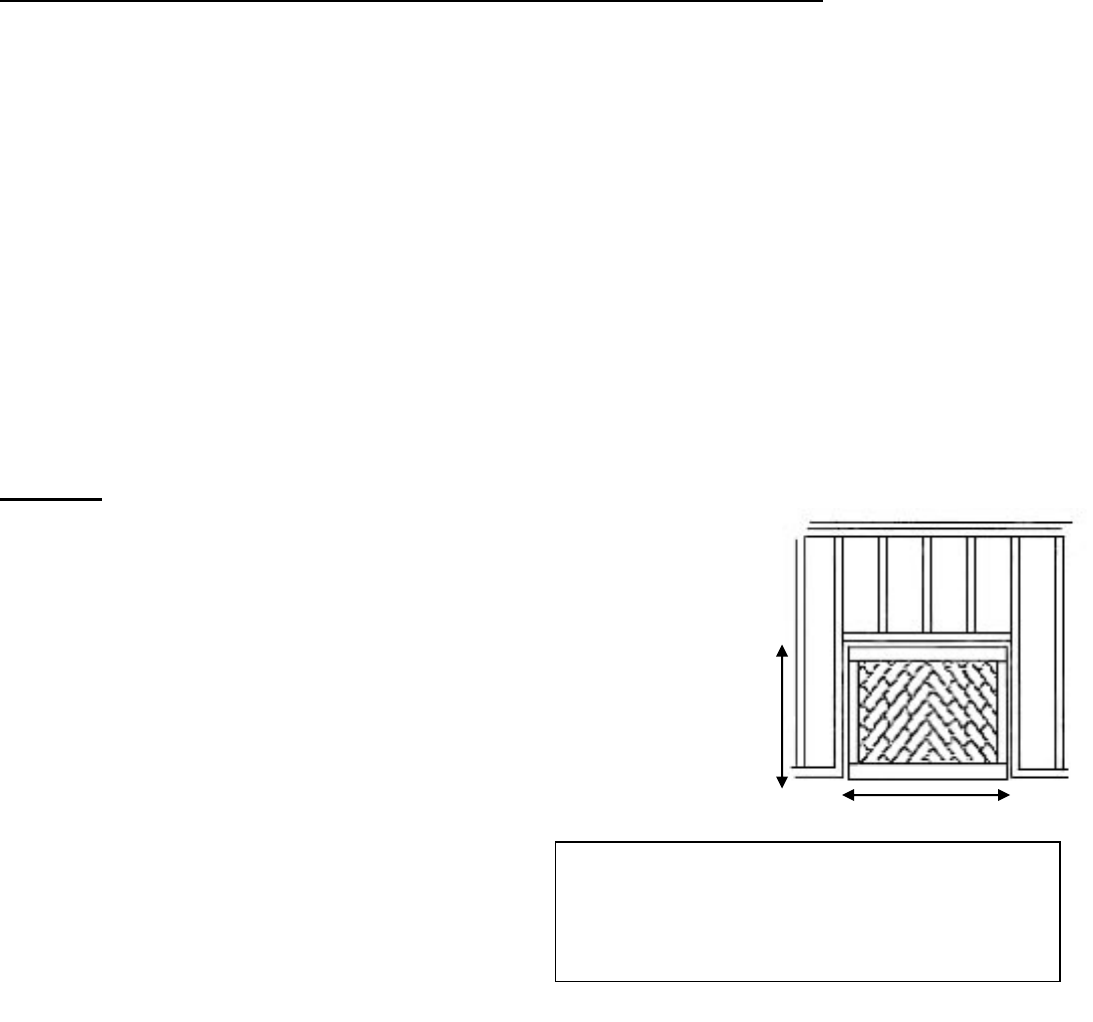

FRAMING DIMENSIONS

Widths A

Height B

Depth

Sonoran 36

44”

39”

27”

Sonoran 42

Sonoran 48

50”

56”

39’

39”

27”

27”

IN SELECTING A LOCATION, THE FOLLOWING PRECAUTIONS MUST BE OBSERVED;

1. Install in an area providing ventilation and adequate combustion air.

2. Due to high temperatures, the Unvented Fireplace should be located out of traffic and away from furniture

and draperies.

3. NEVER obstruct the front opening of the Unvented Fireplace or the flow of combustion and ventilation air. Keep

control compartments accessible.

4. Do not locate in the vicinity where gasoline or other flammable liquids may be stored. The Unvented Fireplace area

must be kept clear and free from these combustible materials.

5. DO NOT INSTALL THIS UNVENTED ASSEMBLY IN SLEEPING QUARTERS.

Preparation for Firebox Assembly

Tools Needed: 4” plastic putty knife or metal drywall knife.

Metal scraper or painter’s tool.

4” disposable coarse paint brush.

Carpenters square.

4’ level.

Optional Tool: SWF assembly jig system. (Frame & Straps.)

FRAMING

Construct framing using dimensions applicable to your particular installation.

If the fireplace is installed on a combustible material, the bottom heat shield is required

with 4” clearance to combustible with 1 ¼” airspace. Framing height is a minimum of

55”. Construct framing using dimensions shown depending on your particular

installation.

A 36" long 1/2” NPT SCHD 40 flexible gas line complying with the National Fuel Gas

Code ANSI Z223.1-1988/NFPA 54, may be run from the regulator to the exterior of the

Unvented Fireplace for access to your incoming 1/2" NPT black iron gas line or you

may route incoming gas line directly to the regulator.

The incoming gas line may be routed towards the Unvented

Fireplace either from the left hand or right hand sides of the

Unvented Fireplace's outer surround. Remove the gas line

cover plate from the Unvented Fireplace's outer

surround at

the location to be used. Remove insulation from inside the

gas line conduit sleeve. Run gas line through until regulator

can be reached.

A sediment trap should be included between incoming gas line and regulator connection.

The sediment trap must extend a minimum of 3" down below the center of the incoming pipe.

Prepare incoming black iron gas line with Teflon tape or pipe joint compound (check with local codes as to the use of

Teflon tape).

Compounds used on threaded joints of gas piping shall be resistant to the action of Liquefied Petroleum (LP or Propane),

and should be applied lightly to ensure excess sealant does not enter the gas line.

Complete your gas installation by connecting incoming gas line to regulator. Secure all joints tightly with wrench but do not

over-tighten. If a flexible gas line is used, take care not to kink connector.

Repack insulation in and around the conduit sleeve and flexible gas line.

B

A