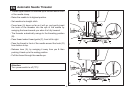

2

1

6

8

7

5

This is a simple operation but it is important to carry out correctly as

by not doing so .

- Start by raising the needle to its highest point (1), and continue

turning the handwheel* counterclockwise until the needle just

slightly begins to descend. You must raise the presser foot to

release the tension discs.

For safety, it is strongly suggested you turn off the power

before threading.

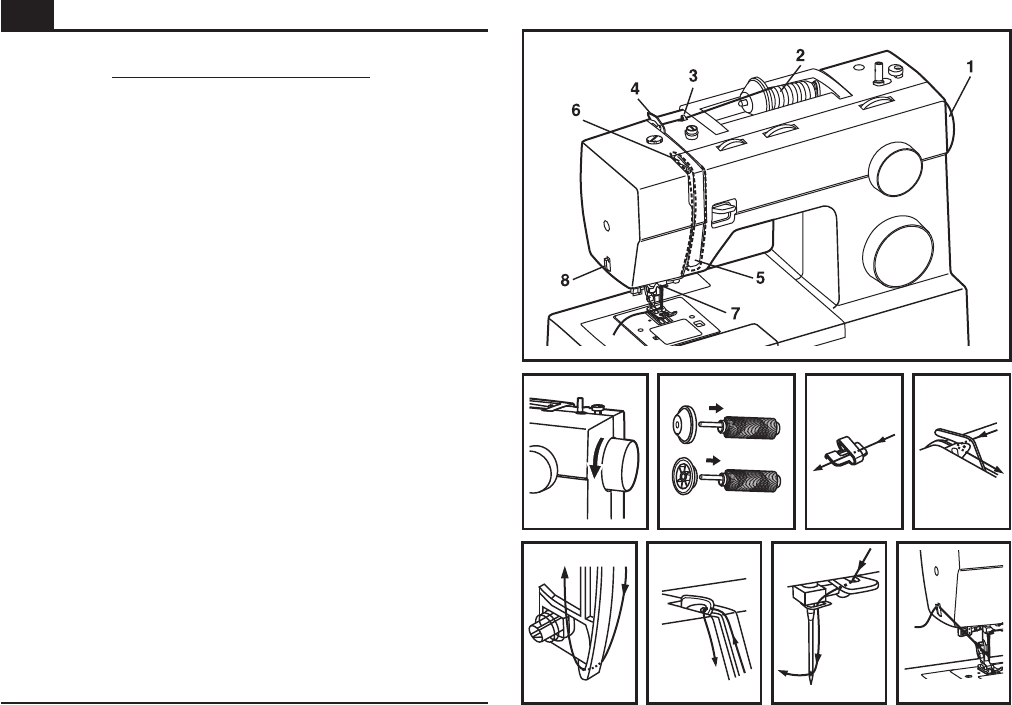

- Lift up the spool pin. Place the spool of thread on the holder with

the thread coming off the spool from the back as shown and

place appropriate spool holder next to the spool. For small

thread spools, place small side of spool holder next to spool. (2)

- Draw thread from spool through the upper thread guide (3) and

pulling thread through pre-tension spring as illustrated. (4)

- Thread tension module by leading thread down right channel. (5)

During this process it is helpful to hold the thread between the

spool and thread guide, as this will help to seat the thread

between the tension discs.

- At the top of this movement pass thread from right to left through

the slotted eye of the take-up lever and then downwards again.

(6)

-

several sewing problems could result

Note:

Now pass the thread behind the horizontal thread guide, and

then behind the thin wire needle clamp guide (7) and then down

to the needle which should be threaded from front to back.

- Pull about 6 - 8 inches of thread under the presser foot to the rear

beyond the needle eye. Trim thread to length with built-in thread

cutter. (8)

* Never turn the handwheel away from you as this may cause the

timing to be disrupted. Always turn the handwheel

counterclockwise (towards you).

3 4

Threading the Upper Thread

EN

16