New Deep Well Installation 7

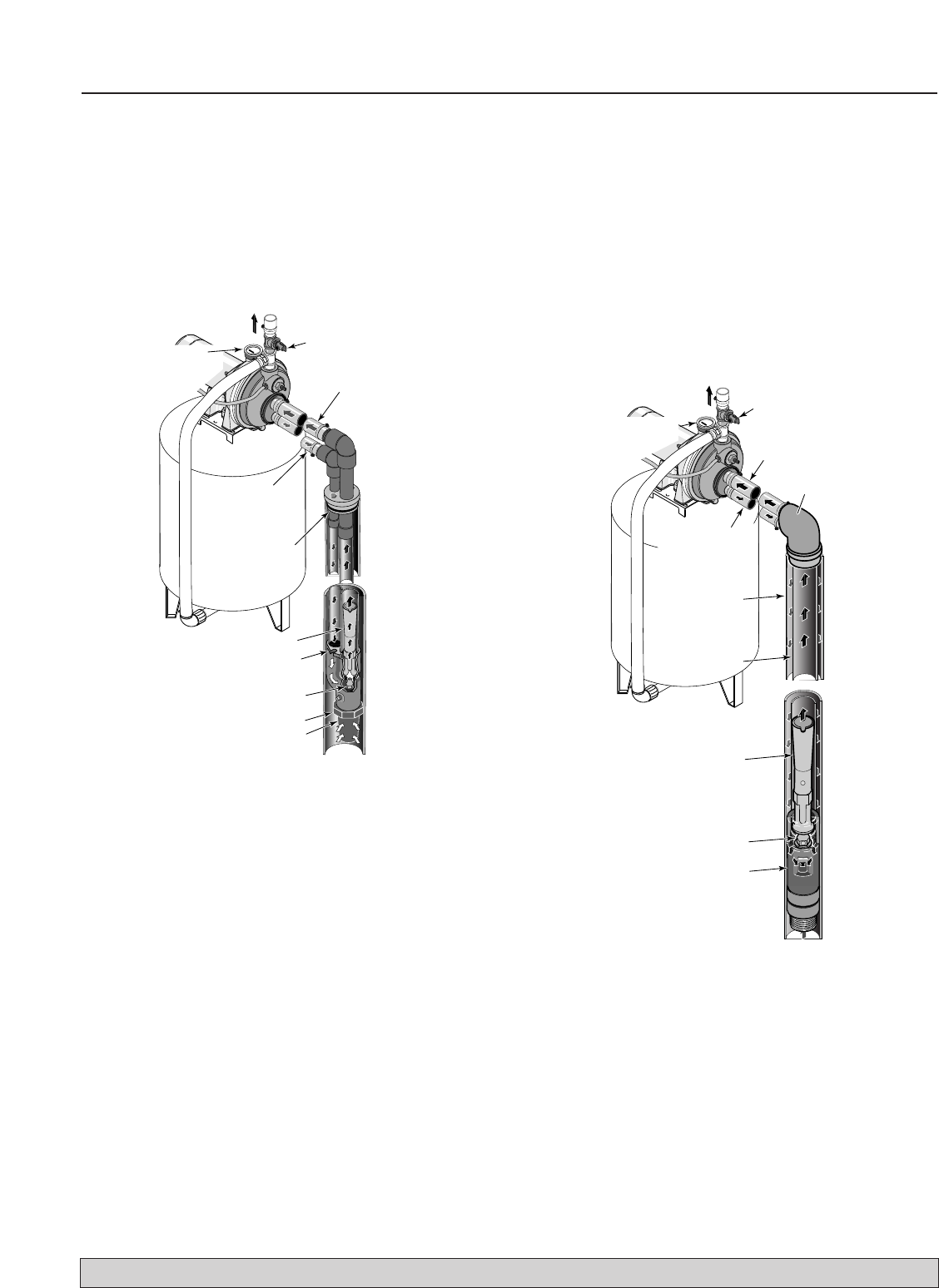

4" OR LARGER WELL (Figure 10)

1. Install the control valve and pressure gauge in the

pump body. See Figure 7.

2. Assemble ejector kit FP4800 or 29660 (sold separate-

ly). See Figure 10. Follow the instructions included

with the kit in order to match the nozzle and venturi

to your well conditions.

3. Mount the pump as close to the well as possible.

4. Connect two pipes (1" drive, 1-1/4" suction) to the ejec-

tor and lower the ejector into the well until it is five feet

from the bottom. It should also be at least 10 feet

below the well’s water level while the pump is running

in order to prevent the pump from sucking air.

5. Install a sanitary well seal and connect the ejector

piping to the pump. Use steel nipples through the

well seal with flexible poly pipe to avoid crushing

the plastic pipe when tightening the seal.

6. Support the pipe so that there are no dips or sags in the

pipe, so it doesn’t strain the pump body, and so that it

slopes slightly upward from the well to the pump (high

spots can cause air pockets which can air lock the

pump). Seal the suction pipe joints with teflon tape or a

teflon based pipe joint compound. Joints must be air-

and water-tight. If the suction pipe can suck air, the

pump cannot pull water from the well.

You have just completed the plumbing for your new

double pipe deep well jet pump. Please go to Page 8 for

discharge pipe and tank connections.

2" WELL (Figure 11)

1. Install the control valve and pressure gauge in the

pump body. See Figure 7.

2. Mount the pump as close to the well as possible.

3. Assemble ejector kit FP4840 or 29670 (sold separate-

ly), well piping, and well head adapter according to

the instructions provided with the ejector package.

See Figure 11. Use galvanized drop pipe with turned

couplings to allow proper flow. Follow the instruc-

tions included with the kit in order to match the noz-

zle and venturi to your well conditions.

4. Run two pipes (one smaller drive pipe, one larger

suction pipe) from the well to the pump. Support the

pipe so that there are no dips or sags in the pipe, so

it doesn’t strain the pump body, and so that it slopes

slightly upward from the well to the pump (high spots

can cause air pockets which can air lock the pump).

Seal the suction pipe joints with teflon tape or a

teflon based pipe joint compound. Joints must be air-

and water-tight. If the suction pipe can suck air, the

pump cannot pull water from the well.

You have just completed the plumbing for your new

single pipe deep well jet pump. Please go to Page 8 for

discharge pipe and tank connections.

P

Suction (Larger)

Pipe from Well

To Household

Water System

Pressure

Gauge and

Priming

Plug

Well

Head

Drive (Smaller)

Line to Well

Venturi

Nozzle

Ejector

Not

to

Scale

Foot Valve

Strainer

266 0395

Relief Valve

For parts or assistance, call Simer Customer Service at 1-800-468-7867 / 1-800-546-7867

Figure 10: 4” and Larger Deep Well

Figure 11: 2” (Single Pipe) Deep Well

41

JET NO.

J32P-

24

P

Suction (Larger)

Pipe

from

Well

To Household

Water System

Pressure Gauge

and Priming

Plug

Well

Head

Drive (Smaller)

Pipe

to

Well

Well Casing

serves as

Drive Pipe

Suction Pipe

Venturi

Nozzle

Ejector

Not

to

Scale

267 0295

Relief Valve