I Electric Furnace Installation Instructions

Changing Motor Speed

The blower motor comes from the factory wired for medium or

high speed. To change the blower speed, disconnect the black

wire at the blower motor termina! block and reconnect at the de-

sired blower speed tap.

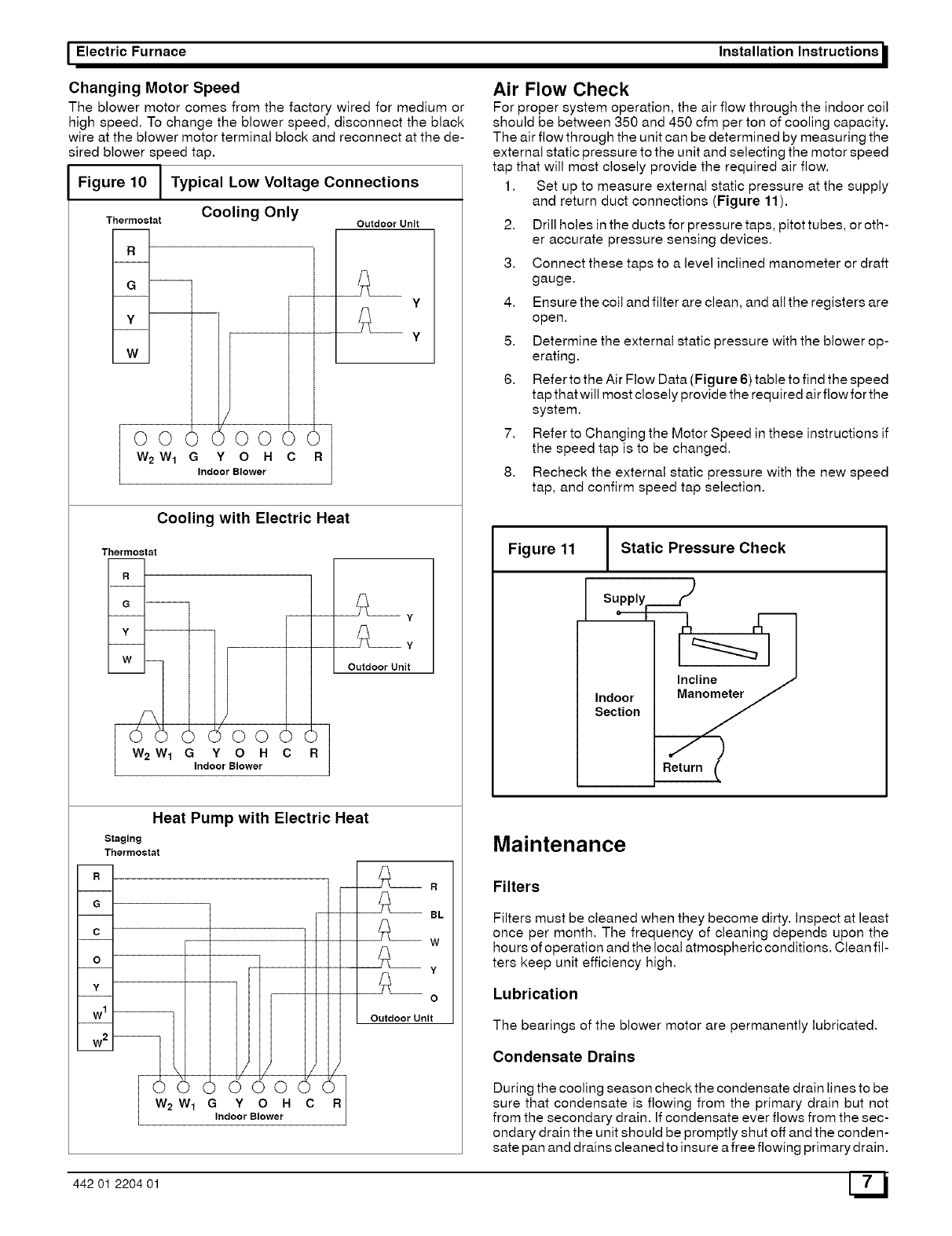

Figure 10 I Typical Low Voltage

Connections

Thermostat Cooling Only

Outdoor Unit

R

G

Y

W

00 0 OOI)

W 2 W 1 G Y O H C R 1

Indoor Blower

Y

Y

Cooling with Electric Heat

Thermostat

R

G --

y --

wOwO ! (> ()

Y

Y

Outdoor Unit

Heat Pump with Electric Heat

Staging

Thermostat

R

BL

W

-- y

O

Outdoor Unit

Air Flow Check

For proper system operation, the air flow through the indoor coil

should be between 350 and 450 cfm per ton of cooling capacity.

The air flow through the unit can be determined by measuring the

external static pressure to the unit and selecting the motor speed

tap that will most closely provide the required air flow.

1. Set up to measure external static pressure at the supply

and return duct connections (Figure 11).

2. Drill holes in the ducts for pressure taps, pitot tubes, or oth-

er accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or draft

gauge.

4. Ensure the coil and filter are clean, and all the registers are

open.

5. Determine the external static pressure with the blower op-

erating.

6. Refer to the Air Flow Data (Figure 6) table to find the speed

tap that will most closely provide the required air flow for the

system.

7. Refer to Changing the Motor Speed in these instructions if

the speed tap is to be changed.

8. Recheck the external static pressure with the new speed

tap, and confirm speed tap selection.

Figure 11

Static Pressure Check

SupplyJ

/nedli°rn

Return _

Maintenance

Filters

Filters must be cleaned when they become dirty. Inspect at least

once per month. The frequency of cleaning depends upon the

hours of operation and the local atmospheric conditions. Clean fil-

ters keep unit efficiency high.

Lubrication

The bearings of the blower motor are permanently lubricated.

Condensate Drains

During the cooling season check the condensate drain lines to be

sure that condensate is flowing from the primary drain but not

from the secondary drain. Ifcondensate ever flows from the sec-

ondary drain the unit should be promptly shut off and the conden-

sate pan and drains cleaned to insure afree flowing primary drain.

442 01 2204 01 7L_