4.Drill6 mountingholesinmarked-offlocationsonthe

wall.Forwoodwallmounting,drill5/16-in.diameter

holes.Formasonrywallmounting,drill5/8-in.diameter

holesandinsert3/8-in.steelshields(anchors).

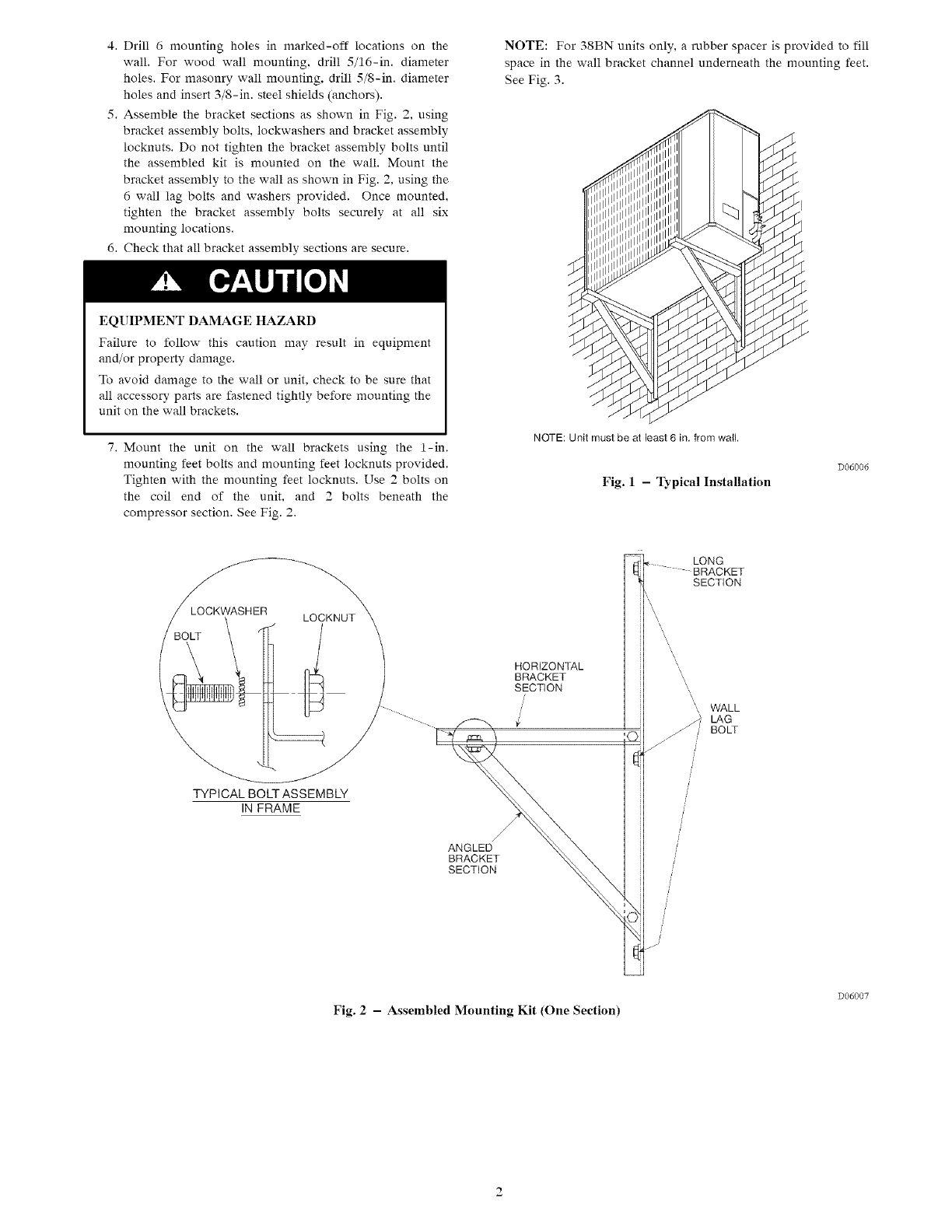

5.AssemblethebracketsectionsasshowninFig.2,using

bracketassemblybolts,lockwashersandbracketassembly

locknuts.Donottightenthebracketassemblyboltsuntil

theassembledkit is mountedonthewall.Mountthe

bracketassemblytothewallasshowninFig.2,usingthe

6walllagboltsandwashersprovided.Oncemounted,

tightenthebracketassemblyboltssecurelyatall six

mountinglocations.

6.Checkthatallbracketassemblysectionsaresecure.

NOTE:For38BNunitsonly,arubberspacerisprovidedtofill

spaceinthewallbracketchannelunderneaththemountingfeet.

SeeFig.3.

EQUIPMENTDAMAGEHAZARD

Failureto followthiscautionmayresultin equipment

and/orpropertydamage.

Toavoiddamagetothewallorunit.checktobesurethat

allaccessorypartsarefastenedtightlybeforemountingthe

unitonthewallbrackets.

7.Mounttheunitonthewallbracketsusingthe1-in.

mountingfeetboltsandmountingfeetlocknutsprovided.

Tightenwiththemountingfeetlocknuts.Use2boltson

thecoil endof theunit,and2 boltsbeneaththe

compressorsection.SeeFig.2.

NOTE: Unit must be at least, ;in. from wail.

Fig. 1 - Typical Installation

D06006

/

LOCKWASHER LOCKNUT

/BOLT\ /

TYPICAL BOLT ASSEMBLY

IN FRAME

ANGLED

BRACKET

SECTION

HORIZONTAL

BRACKET

SECTION

/

;KET

SECTION

', WALL

/_.} LAG

j / BOLT

Fig. 2 - Assembled Mounting Kit (One Section)

D06007