INSTALLATION / OPERATION

INSTALLATION

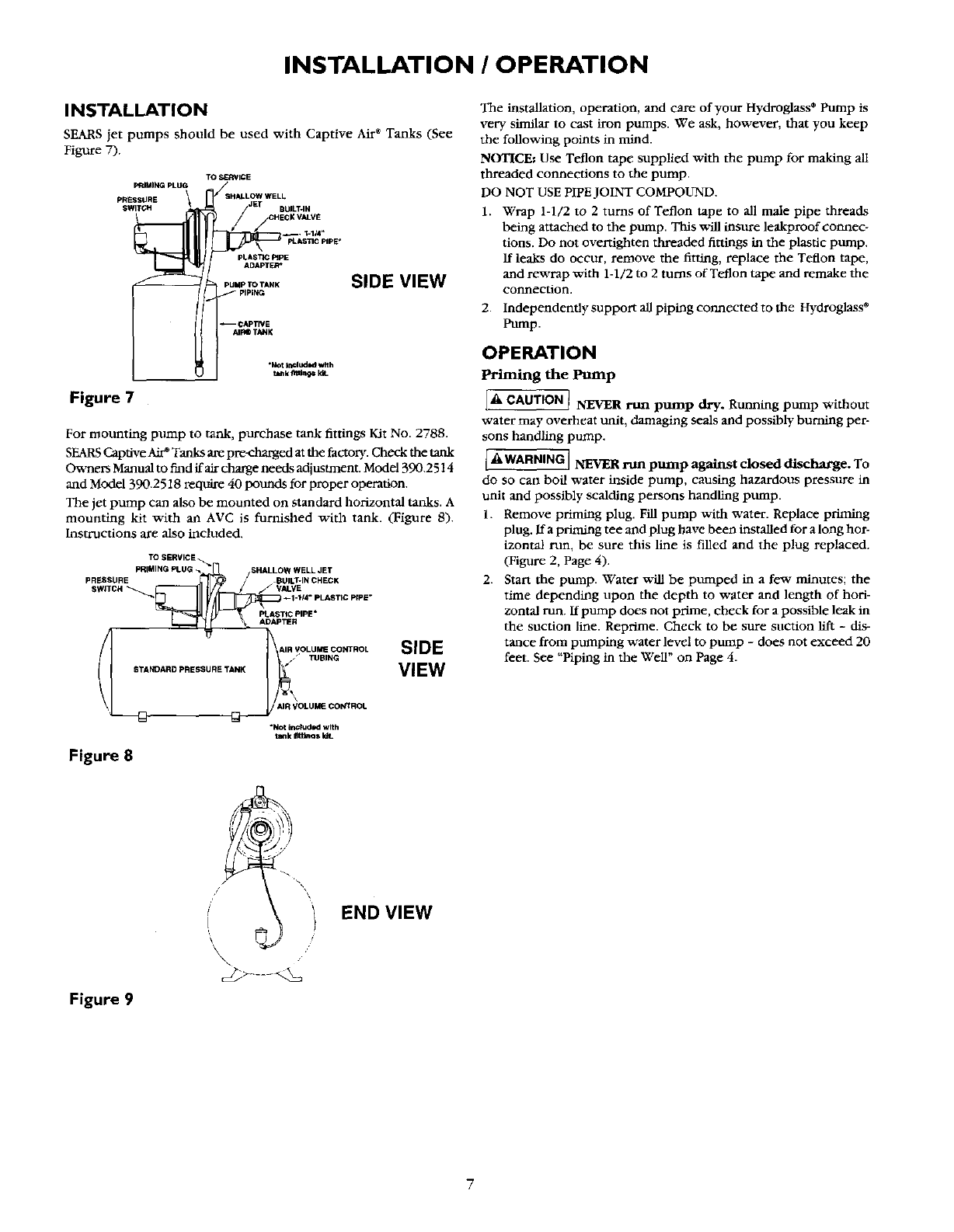

SEARS jet pumps should be used with Captive Air* Tanks (See

Figure 7).

I_IMINGpLU8

PRESSURE

$WITGH

TO,_ICE

BUILT-IN

( VALVE

__. 1-114"

pLASTIC pIp_

pLASTIC FtPE

ADAPTER*

PUMPTOTANK

SIDE VIEW

;ApTNE

AIF_ TANK

Figure 7

For mounting pump to tank, purchase tank fittings Kit No. 2788.

SEARS Captive Ai_ Tanks are pre_.harged at the factory. Check the tank

Owners Manual to find if air charge needs adjustmem. Model 390.2514

and Model 390.2518 require 40 pounds for proper operation.

The jet pump can also be mounted on standard horizontal tanks. A

mounting kit with art AVC is furnished with tank. (Figure 8).

Instructions are aIso included.

TO SERVICE _

PRIMING PLUG _ SHALLOW WELL JET

pRESSURE / / .BUILT.IN CHEC K

I I /," TUBINGSTANDARD PRESSURE TANK I_ x VIEW

\l _ _ J/".VOLU_CO_ROL

"Not _tudsd with

ta_k fltt_as kit.

Figure 8

Figure 9

\.

END VIEW

The installation, operation, and care of your Hydroglass ®Pump is

very similar to cast iron pumps. We ask, however, that you keep

the following points in mind.

NOTICE: Use Teflon tape supplied with the pump for making aU

threaded connections to the pump.

DO NOT USE PIPE JOINT COMPOUND.

1. Wrap 1-1/2 to 2 turns of Teflon tape to all male pipe threads

being attached to the pump. This will insure leakproof connec-

tions. Do not overtighten threaded fittings in the plastic pump.

If leaks do occur, remove the fitting, replace the Teflon tape,

and rewrap with 1-1/2 to 2 turns of Teflon tape and remake the

connection.

2. Independently suppo_ all piping connected to the Hydroglass ®

Pump.

OPERATION

Priming the Pump

l_k CAUTION_ NEVER run pump dry. Running pump without

water may overheat unit, damaging seals and possibly burning per-

sons handling pump.

m

LA WARNING_ NEVER run pump against closed discharge. To

do so can boil water inside pump, causing hazardous pressure in

unit and possibly scalding persons handling pump.

1. Remove priming plug. Fill pump with water. Replace priming

plug. If a priming tee and plug have been instailed for a long hor-

izontal run, be sure this line is filled and the plug replaced.

(Figure 2, Page 4).

2. Start the pump. Water will be pumped in a few minutes; the

time depending upon the depth to water and length of hori-

zontal run. If pump does not prime, check for a possible leak in

the suction line. Reprime. Check to be sure snction lift - dis-

tance from pumping water level to pump - does not exceed 20

feet. See "Piping in the Well" on Page 4.