Combustion Air and Ventilation

for Appliances Located in

Unconfined Spaces

-UnconfinedSpaceis a spacewhose volume is not lessthan 50

cubic feet per 1,000 Btuper hour of the aggregateinput rating

of all appliances installed in that space.Roomscommunicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, are considered a

part of the unconfined space

in unconfined spacesin buildings, infiltration maybe adequate

to provide air for combustion, ventilation and dilution of flue

gases.However, in buildings of tight construction (for example,

weather stripping, heavily insulated, caulked, vapor barrier,

etc.), additional air may need to be provided usingthe methods

described in Combustion Air and Ventilation for Appliances

Locatedin Confined Spaces.

Combustion Air and Ventilation

'for Applia_ncesLocated in

Confined Spaces

Confined Spaceis a spacewhose volume is lessthan 50 cubic

feet per 1,000 Btu per hour of the aggregateinput rating of all

appliances installed in that space.

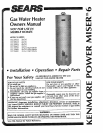

a. ALLAIR FROMINSIDE BUILDINGS:

(SeePage8 Figure1, and Figure.2 below)

The confined spaceshall be provided with two permanent

openingscommunicating directly with an additional room(s)

of sufficient volume so that the combined volume of all

spacesmeetsthe criteria for an unconfined space. The total

input of all gas utilization equipment installed in the

combined space shall be considered in making this

determination. Eachopening shall have a minimum free area

of one square inch per 1,000 Btu per hour of the total input

rating of all gas utilization equipment in the confined space,

but not less than 100 square inches. One opening shall

commencewithin t2 inchesof the top and one commencing

within 12 inchesofthe bottom ofthe enclosure.

FUR._.F. I WAT_II (LOUVERS,_._F.F_S. Er¢._

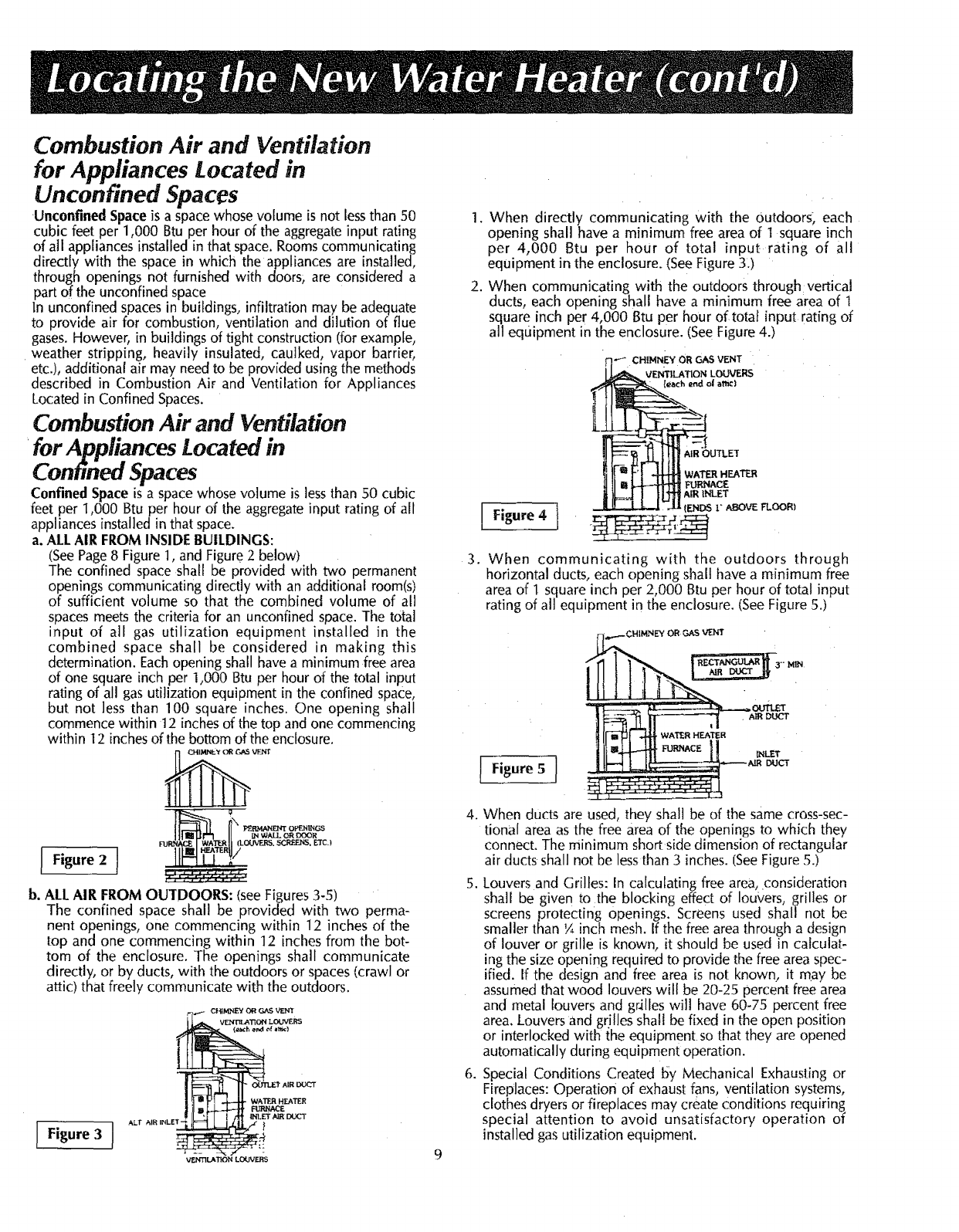

b. ALLAIR FROMOUTDOORS: (see Figures 3-5)

The confined space shall be provided with two perma-

nent openings, one commencing within 12 inches of the

top and one commencing within 12 inches from the bot-

tom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawl or

attic) that freely communicate with the outdoors.

1Figure 3 I

If

!_==_ '] _ WAT'F_ HFJ_-TER

Jliln kg_l---tt _E

VE@'nLA]ION LOLtV_S

1. When directly communicating with the Outdoors, each

opening shall have a minimum free area of I square inch

per 4,000 Btu per hour of total input rating of all

equipment in the enclosure. (See Figure 3.)

2. When communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 Btu per hour of total input rating of

all equipment in the enclosure. (See Figure 4.)

Figure4 1

Q'_" CHIMNEY OR GAS VENT

iJ_,_ VE_T,U_IONLOU'._RS

each end ol atilt)

U'rLET

!l= Yi 4t4fl WATERH_a_

II]1=,_ _cE

11_-4 I ILlllA_RIN_T

Jti IEND_ 1" ABOVE FLOOR)

3. When communicating with the outdoors through

horizontal ducts, each opening shah have a minimum free

area of 1 squareinch per 2,000 Btu per hour of total input

rating of all equipment in the enclosure. (SeeFigure5.)

I_EY OR GAS VENT

INLET

4. When ducts are used, they shall be of the same cross-sec-

tional area as the free area of the openings to which they

connect. The minimum short side dimension of rectangular

air ducts shall not be less than 3 inches. (See Figure 5.)

5. Louvers and Grilles: In calculating free area, consideration

shall be given to the blocking effect of Iou_,ers, grilles or

screens protecting openings. Screens used shall not be

smaller than ¼ inch mesh. ffthe free area through a design

of louver or grille is known, it should be used in calculat-

ing the size opening required to provide the free area spec-

ified. If the design and free area is not known, it may be

assumed that wood louvers will be 20-25 percent free area

and metal louvers and grilles will have 60-75 percent free

area. Louvers and grilles shah be fixed in the open position

or interlocked with the equipment so that they are opened

automatically during equipment operation.

6. Special Conditions Created by Mechanical Exhausting or

Fireplaces: Operation of exhaust fans, ventilation systems,

clothes dryers or fireplaces may create conditions requiring

special attention to avoid unsatisfactory operation of

installed gas utilization equipment.