ELECTRICAL WORK / INSTALLATION METHOD

INSTALLATION METHOD

INSTALLATION METHOD

Installation Procedures

1. Open the inlet grille, and remove the flare nut.

2. Bend the connection pipe to an appropriate length using the spring bender depending

upon the installation place.

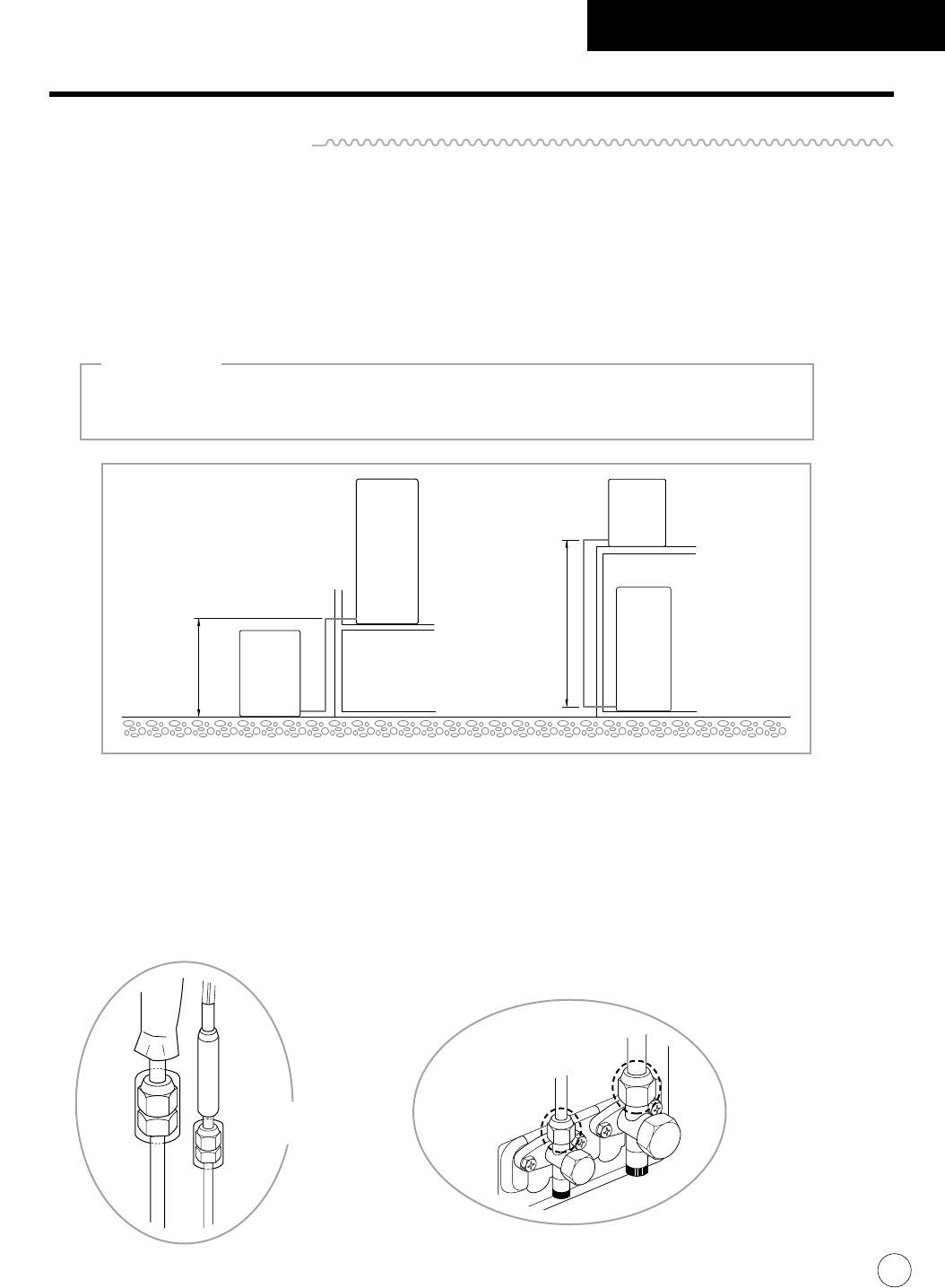

- Allowable pipe length : Maximum 25m(82ft)

- Allowable pipe drop distance : Maximum 15m(49ft)

- Make no more than ten bending points on the pipe

❈ When the pipe length is in excess of the standard pipe length of 5m(16ft 5 in), add the refrigerant

(R-22) of 50g(0.11lb) for each additional 1m(3.28ft).

3. Install the high pressure pipe to the heat exchanger liquid pipe, and the low pressure pipe to the

heat exchanger gas pipe respectively using the flare nut, taking care not to cause any leakage of refrigerant.

4. Be sure to insulate the pipe with appropriate insulation material.

5. Insert the drain hose into the drain pipe, and connect them by tying them to the cable tie to prevent

any water leakage.

6. After completion of the installation, check the connecting area for any gas leakage.

7. Wind a finish tape when the wiring of the refrigerant pipe, the unit, and the drain piping are completed.

Less than 15m(49ft)

Less than 15m(49ft)

Outdoor

unit

Outdoor

unit

Indoor

unit

Indoor

unit

Outdoor unit

checking area

Indoor unit

checking area

CAUTION

◆ If the pipe is lengthened, the performance of the unit is degraded, and the service life is shortened.

Therefore, the pipe length should be as short as possible (less then 15m/49ft).

E-

25