SECTION 10: OUTSIDE AIR SUPPLY

37

SECTION 10: OUTSIDE AIR SUPPLY

The CRV-Series system is approved for use with an

outside air system. Halogenated hydrocarbons or

other corrosive chemicals in the air can be drawn into

the equipment and seriously damage the system

components. Avoid the use of such chemical

compounds near the air inlet to the heaters.

IMPORTANT: If the building has a slight negative

pressure or contaminants are present in the air, an

outside combustion air supply to the heaters is

strongly recommended.

All joints and seams in the air supply system must be

airtight. Attach the filter housing to the burner

assembly using the wing nut provided.

10.1 Pressurized

See Page 39, Figure 23 for a typical layout of a

pressurized air supply system.

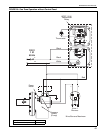

For pressurized outside air supplies, the outside air

blower motor has a pressure switch interlock that

must be used. Wire this switch in series with the

pump pressure switch. When using an outside air

blower with a ROBERTS GORDON

®

System Control

or ROBERTS GORDON

®

ULTRAVAC

™

control or

relay transformer, a separate load relay package is

required. Wire the control for the relay in parallel with

the pump. The outside air blower must have a

separate 20A, 120V power supply. See Page 38,

Figure 21 for outside air blower internal wiring

requirements.

10.2 Non-Pressurized

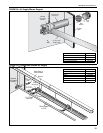

For a non-pressurized outside air supply, a 4" (O.D.)

single wall pipe duct may be attached to the burner

and end vent. For length and duct sizing

requirements, see duct design rules in Figure 19. To

prevent condensation, insulate the outside air duct.

FIGURE 19: Duct Sizing

Outside Air System Design Requirements:

Blower Performance (90707501):

112 Flow Units

One outside air blower is required per each EP-100 or

EP-200 series pump and two outside air blowers may

be required for each EP-300 series pump. Outside air

blowers cannot be shared between two separate CRV-

Series systems.

Duct Design Rules:

- System should be designed so that the blower is

positioned closest to the highest flow

requirements (end vents).

- When a duct is carrying more than 40 flow units, it

must be at least 6" (15 cm) diameter.

Pressurized Systems

- 6" (15 cm) diameter duct must not exceed 120'

(36 m) total per system.

- 4" (10 cm) diameter duct must not exceed 120'

(36 m) per radiant branch.

Non Pressurized

- 6" (15 cm) diameter duct must not exceed 90'

(27 m) maximum 100 flow units

- 4" (10 cm) diameter duct must not exceed 90'

(27 m)

- Elbows are equivalent to 10' (3 m) of duct length.