SECTION 13: SERVICING

31 of 47

SECTION 13: SERVICING

13.1 Servicing Instructions

After start-up, the heater will require maintenance to

be carried out, at a minimum, annually. If the heater

is used in a dirty or dusty area, more frequent

maintenance may be required.

IMPORTANT: After any maintenance or repair work,

always test fire the heater in accordance with the

start-up instructions on Page 26, Section 11 through

Page 28, Section 11.3.1 to ensure all safety systems

are in working order before leaving the heater to

operate. Minor faults may be traced by using the

troubleshooting charts on Page 34, Section 14

through Page 38, Section 14.5.

IMPORTANT: Check all gas pipes and pipe joints to

ensure there are no cracks or gas leaks. Any cracks

in the pipes or pipe joints must be repaired.

IMPORTANT: Inspect all suspended components

and hardware. Ensure that they are in good

condition, properly tightened, and corrosion free.

13.2 Burner Maintenance

1. Open the door and remove the burner

compartment cover. See Page 40, Section

15.2.

2. Clean any deposits from the main burner which

may have formed in the injectors or venturi of

the bu

rner. See Page 40, Section 15.2.1.

3. Remove the ignition electrode and flame probe.

Check condition of ignition electrode and flame

probe. Clean off any deposits which may have

been formed, check condition of ceramic

insulators. Replace as required. See Page 41,

Figure 15.3.

13.3 Heat Exchanger Maintenance

The heat exchanger will remain clean unless a

problem has developed with combustion. Inspect the

heat exchanger. Look for signs of overheating at the

front tubes which may indicate burner over firing or

persistently low air flows.

13.4 Gas Valve Maintenance

No regular maintenance is required on this device.

To change gas control valves, See Page 39, Section

15.1.

Do not repair or disassemble gas valve.

Replace faulty gas valves with replacement parts

sold and supplied by Roberts-Gordon LLC.

13.5 Flue Blower

The flue blower should not require maintenance.

However, if the air pressure switch is causing burner

lockout, then remove the flue blower from the vent

box by unscrewing the three screws at the mounting

plate. Remove the four scre

ws attaching the

mounting plate to the fan inlet (See Page 42,

Section 15.5). Ensure that the fan is free to run and

that the fan wheel is clean.

13.6 Venting and Air Intake Pipe

Inspect all venting and air intake pipe. Ensure that

all seams are sealed and suspension points secure.

Repair suspension points if any part of the venting

or combustion air pipe is sagging. Check to make

sure any insulation is not missing or in poor

condition. Replace as required. Check all venting

and air intake components to ensure they are in

good condition, gas tight and corrosion-free.

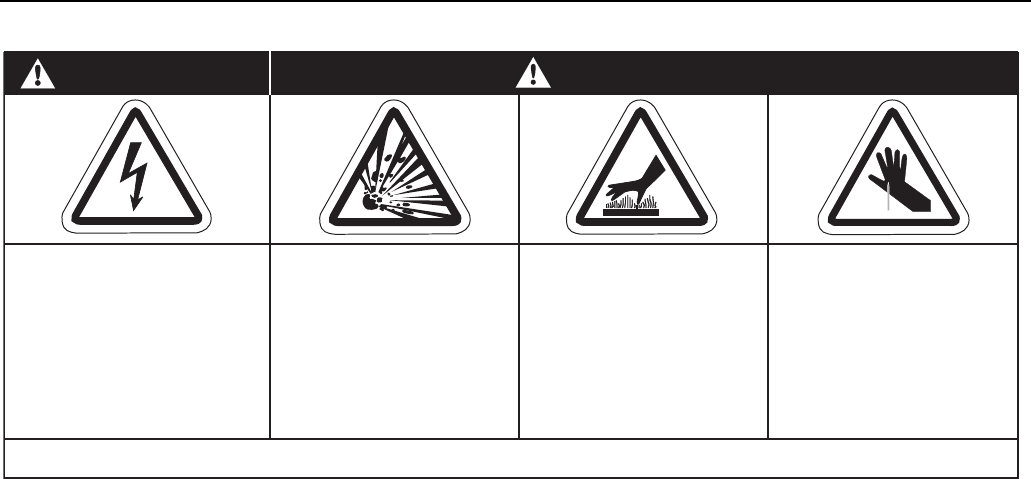

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

DANGER

Electrical Shock Hazard

Disconnect electric

before service.

Heater must be

connected to a properly

grounded electrical

source.