Installing the water heater.

6

Thermal Expansion

Typical Installation

Determine if a check valve exists in the inlet water line. It may have been installed

in the cold water line as a separate back flow preventer, or it may be part of a pressure

reducing valve, water meter or water softener. A check valve located in the cold water inlet

line can cause what is referred to as a “closed water system”. A cold water inlet line with

no check valve or back flow prevention device is referred to as an “open” water system.

As water is heated, it expands in volume and creates an increase in the pressure within

the water system. This action is referred to as “thermal expansion”. In an “open” water

system, expanding water which exceeds the capacity of the water heater flows back into

the city main where the pressure is easily dissipated.

A “closed water system”, however, prevents the expanding water from flowing back into

the main supply line, and the result of “thermal expansion” can create a rapid and

dangerous pressure increase in the water heater and system piping. This rapid pressure

increase can quickly reach the safety setting of the relief valve, causing it to operate during

each heating cycle. Thermal expansion, and the resulting rapid and repeated expansion and

contraction of components in the water heater and piping system can cause premature

failure of the relief valve, and possibly the heater itself. Replacing the relief valve will not

correct the problem!

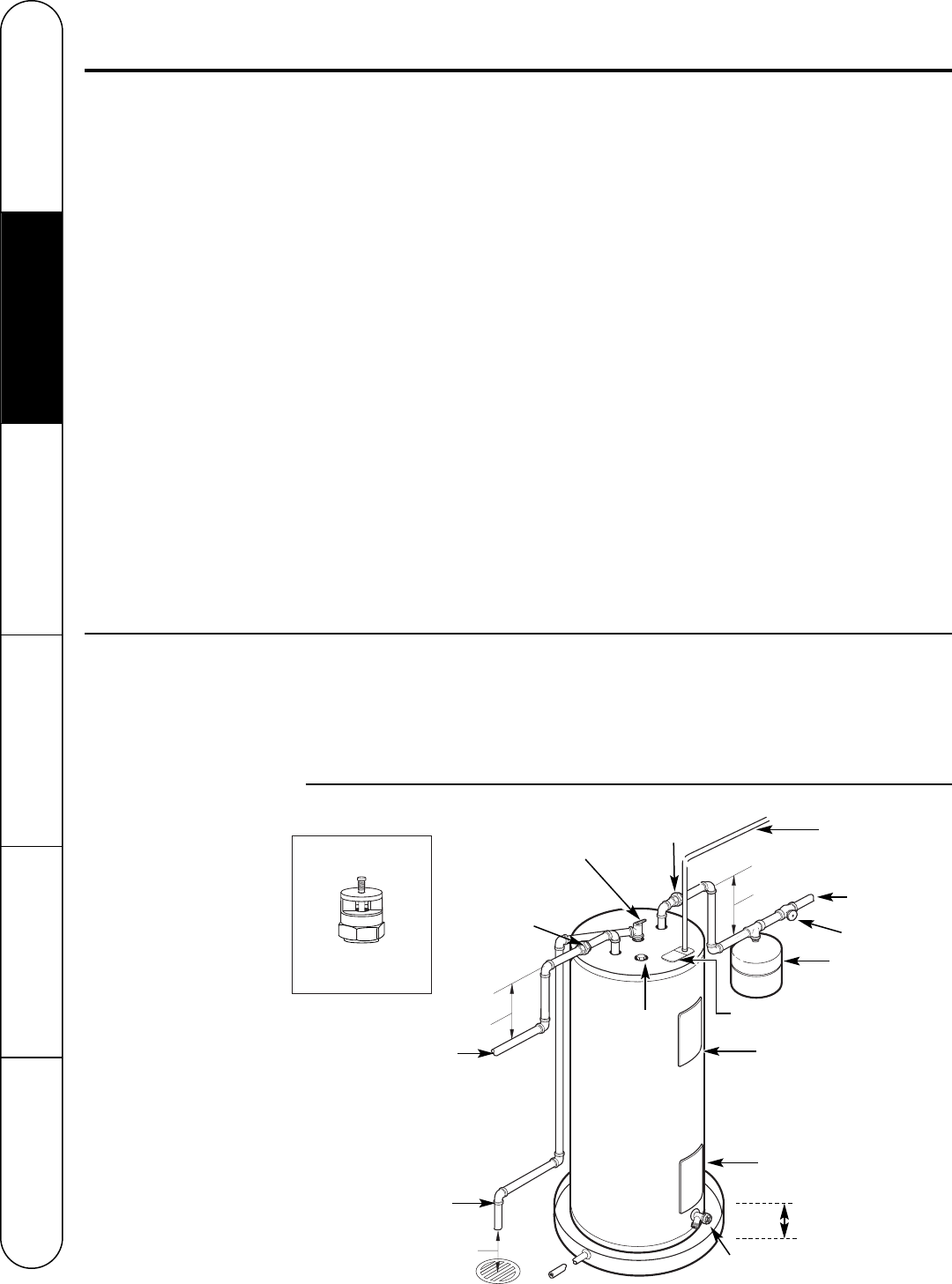

The suggested method of controlling thermal expansion is to install an expansion tank in

the cold water line between the water heater and the check valve (refer to the illustration

below). The expansion tank is designed with an air cushion built in that compresses as the

system pressure increases, thereby relieving the over pressure condition and eliminating the

repeated operation of the relief valve. Other methods of controlling thermal expansion are

also available. Contact your installing contractor, water supplier or plumbing inspector for

additional information regarding this subject.

R

E

L

I

E

F

V

A

L

V

E

COLD

H

OT

To electrical

distribution panel

Heat trap

6″ minimum

Heat trap

6″ minimum

To cold water

supply

Jacket access panel

Relief valve discharge line

to suitable open drain

Jacket access panel

Auxiliary catch pan

2″ maximum

Drain valve

Electrical junction box

(use only copper conductors)

Hot water outlet

to fixtures

6″ air gap

Anode

Shut-off valve

Union

Temperature and

pressure relief valve

Union

NOTICE: Do not apply heat

to the HOT or COLD water

connections. If sweat

connections are used,

sweat tubing to adapter

before fitting adapter to the

water connections on

heater. Any heat applied to

the water supply fittings

will permanently damage

the dip tube and/or heat

traps.

Customer Service Troubleshooting Tips Care and Cleaning Operating Instructions Installation Instructions Safety Instructions

Water Supply Connections

Refer to the illustration below for suggested typical installation. The installation of

unions or flexible copper connectors is recommended on the hot and cold water

connections so that the water heater may be easily disconnected for servicing if

necessary. The HOT and COLD water connections are clearly marked and are 3/4″ NPT

on all models. Install a shut-off valve in the cold water line near the water heater.

Thermal

expansion tank

(if required)

Vacuum Relief Valve

(Not Supplied)

If required, install per local codes

and valve manufacturer’s

instructions.