UltraGlow G36D Zero Clearance Direct Vent Gas Fireplace 21

INSTALLATION

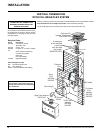

Diagram 3

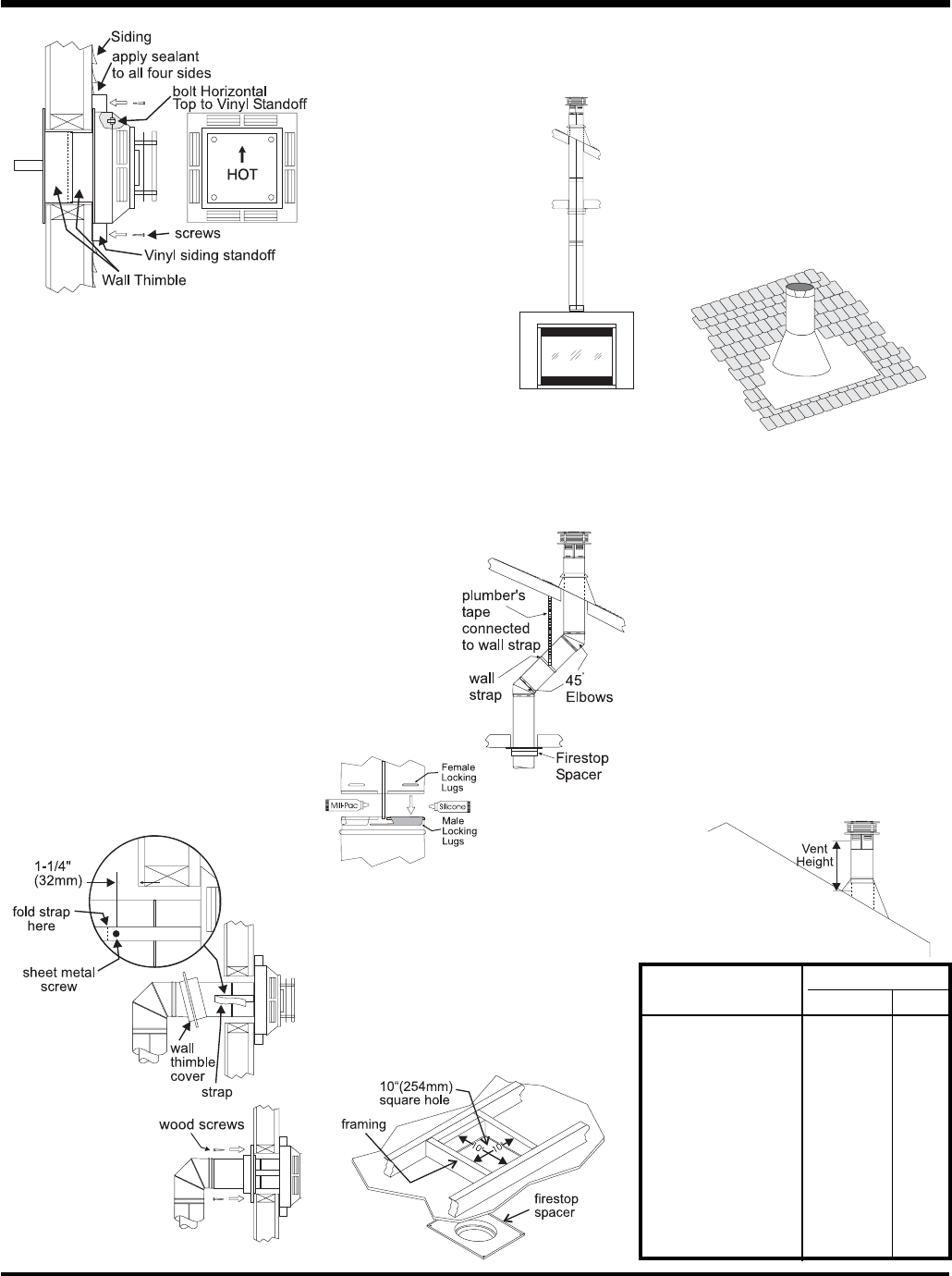

Diagram 5

Diagram 1

Diagram 2

Note: Apply sealant "Mill-Pac" to inner pipe

and high temperature silicone seal-

ant to outer pipe on every twist-lock

joint.

Diagram 5

Diagram 6

VERTICAL

TERMINATION

1) Maintain the 1-1/2" clearances

(air spaces) to combustibles

when passing through ceilings,

walls, roofs, enclosures, attic

rafter, or other nearby combus-

tible surfaces. Do not pack air

spaces with insulation. Check

pages 13-16 for the maximum

vertical rise of the venting

system and the maximum hori-

zontal offset limitations.

Diagram 7

The four wood screws provided should

be replaced with appropriate fasteners for

stucco, brick, concrete, or other types of

sidings.

Note: If installing termination on a siding

covered wall, a vinyl siding standoff

or furring strips must be used to

ensure that the termination is not

recessed into the siding.

7) Before connecting the horizontal run of vent

pipe to the vent termination, slide the Wall

Thimble (Part # 942) over the vent pipe.

8) Slide the appliance and vent assembly

towards the wall carefully inserting the

vent pipe into the vent cap assembly. It is

important that the vent pipe extends into

the vent cap suffi cient distance so as to

result in a minimum pipe overlap of 1-1/4

inches. Secure the connection between the

vent pipe and the vent cap by attaching the

two sheet metal strips extending from the

vent cap assembly into the outer wall of the

vent pipe. Use the two sheet metal screws

provided to connect the strips to the pipe

section. See Diagram 6.

9) Install wall thimble in

the center of the 10"

square and attach

with wood screws

(Diagram 7).

2) Set the gas appliance in

its desired location. Drop

a plumb bob down from

the ceiling to the position

of the appliance fl ue exit,

and mark the location where the vent will

penetrate the ceiling. Drill a small hole at

his point. Next, drop a plumb bob from the

roof to the hole previously drilled in the ceil-

ing, and mark the spot where the vent will

penetrate the roof. Determine if ceiling joists,

roof rafters or other framing

will obstruct the vent-

ing system.

You may wish

to relocate

the appliance

or to offset,

as shown in

Diagram 2 to

avoid cutting

load bearing

members.

3) A Firestop spacer must be installed in the

fl oor or ceiling of every level. To install the

Firestop spacer in a fl at ceiling or wall, cut a

10 inch square hole. Frame the hole as shown

in Diagram 3 and install the fi restop.

4) Assemble the desired lengths of pipe and

elbows. Ensure that all pipes and elbow

connections are in the fully twist-locked

position and sealed.

5) Cut a hole in the roof centered on the small

drilled hole placed in the roof in Step 2. The

hole should be of suffi cient size to meet

the minimum requirements for clearance

to combustibles of 1-1/2". Slip the fl ashing

under the shingles (shingles should overlap

half the fl ashing) as per Diagram 4.

Diagram 4: The upper half of the fl ashing is

installed under the roofi ng material and not

nailed down until the chimney is installed. This

allows for small adjustments.

6) Continue to assemble pipe lengths.

Note: If an offset is necessary in the attic

to avoid obstructions, it is important

to support the vent pipe every 3 feet,

to avoid excessive stress on the el-

bows, and possible separation. Wall

straps are available for this purpose

(Diagram 2).

Galvanized pipe is desirable above the roof-

line due to its higher corrosion resistance.

Continue to add pipe sections through the

fl ashing until the height of the vent cap meets

the minimum height requirements specifi ed

Roof Pitch Minimum Vent Height

Feet Meters

fl at to 7/12 2 0.61

over 7/12 to 8/12 2 0.61

over 8/12 to 9/12 2 0.61

over 9/12 to 10/12 2.5 0.76

over 10/12 to 11/12 3.25 0.99

over 11/12 to 12/12 4 1.22

over 12/12 to 14/12 5 1.52

over 14/12 to 16/12 6 1.83

over 16/12 to 18/12 7 2.13

over 18/12 to 20/12 7.5 2.29

over 20/12 to 21/12 8 2.44