VENT PIPING

WARNING: Indoor heaters require a drafthood that

must be connected to a vent pipe and properly vented

to the outside. Failure to follow this procedure can

cause fire or fatal carbon monoxide poisoning.

Vent piping of the same size as the drafthood outlet

is recommended, however, when the total vent height

is at least ten (10) feet (drafthood relief opening to vent

terminal), the vent pipe size may be reduced as speci-

fied in Chapter 10 of the National Fuel Gas Code, ANSI

Z 223.1. Avoid long horizontal runs of vent pipe and too

many elbows. If installation requires horizontal non-

vertical runs, the vent pipe must have a minimum of

1/4 inch per foot rise and should be supported at not

more than five foot intervals. Plumber's tape, criss-

crossed, will serve to space both horizontal and vertical

piping. Gas vents supported only by the flashing and

extending above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads. We recommend use of an insulated vent pipe

spacer through the roofs and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a vent cap which com-

plies with the local codes or, in the absence of such

codes, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1.

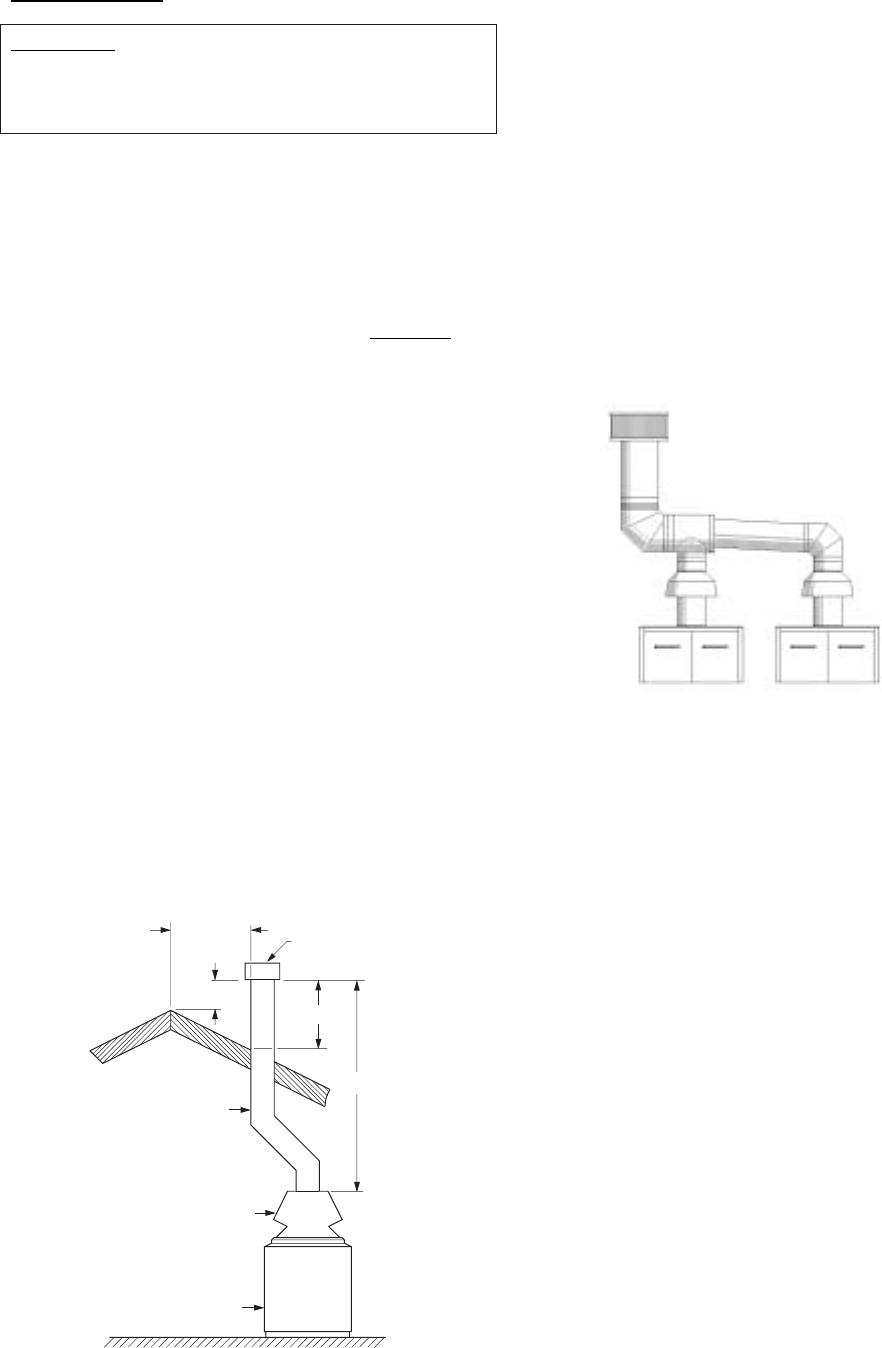

The discharge opening must be a minimum of two

feet vertically from the roof surface and at least 2 feet

higher than any part of the building or equipment within

ten feet. The vent stack shall be at least 5 feet in vertical

height above the drafthood outlet. The vent cap loca-

tion shall have a minimum clearance of 4 feet horizon-

tally from, and in no case above or below, unless a 4-

foot horizontal distance is maintained, from electric

meters, gas meters regulators and relief equipment.

.

14

Fig. #7043.1

At the time of removal of an existing heater, the follow-

ing steps shall be followed with each appliance remain-

ing connected to the common venting system placed in

operation, while the other appliances remaining con-

nected to the common venting system are not in

operation.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and make sure there is no

blockage or restriction, leakage, corrosion or

other deficiency which could cause an unsafe

condition.

(c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com-

mon venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will oper-

ate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

The weight of the vent stack or chimney must not rest

on heater drafthood. Support must be provided in

compliance with applicable codes. The heater top and

drafthood must be readily removable for maintenance

and inspection. Vent pipe should be adequately sup-

ported to maintain proper clearances from combustible

construction Type "B" double wall or equivalent vent

pipe is recommended. However single wall metal vent

pipe may be used as specified in the latest edition of the

National Flue Gas Code ANSI Z223.1.

Manifolds that connect more than one heater to a

common chimney must be sized to handle the com-

bined load. Consult available guides for proper sizing

of the manifold and the chimney. At no time should the

area be less than the area of the largest outlet.

5' MIN

2' MIN

10' OR LESS

2' MIN

VENT CAP

VENT PIPE

DRAFT HOOD

HEATER