11

Models 0330, 0331, 0400 & 0401

Vent Terminal/Indoor Stack Installation

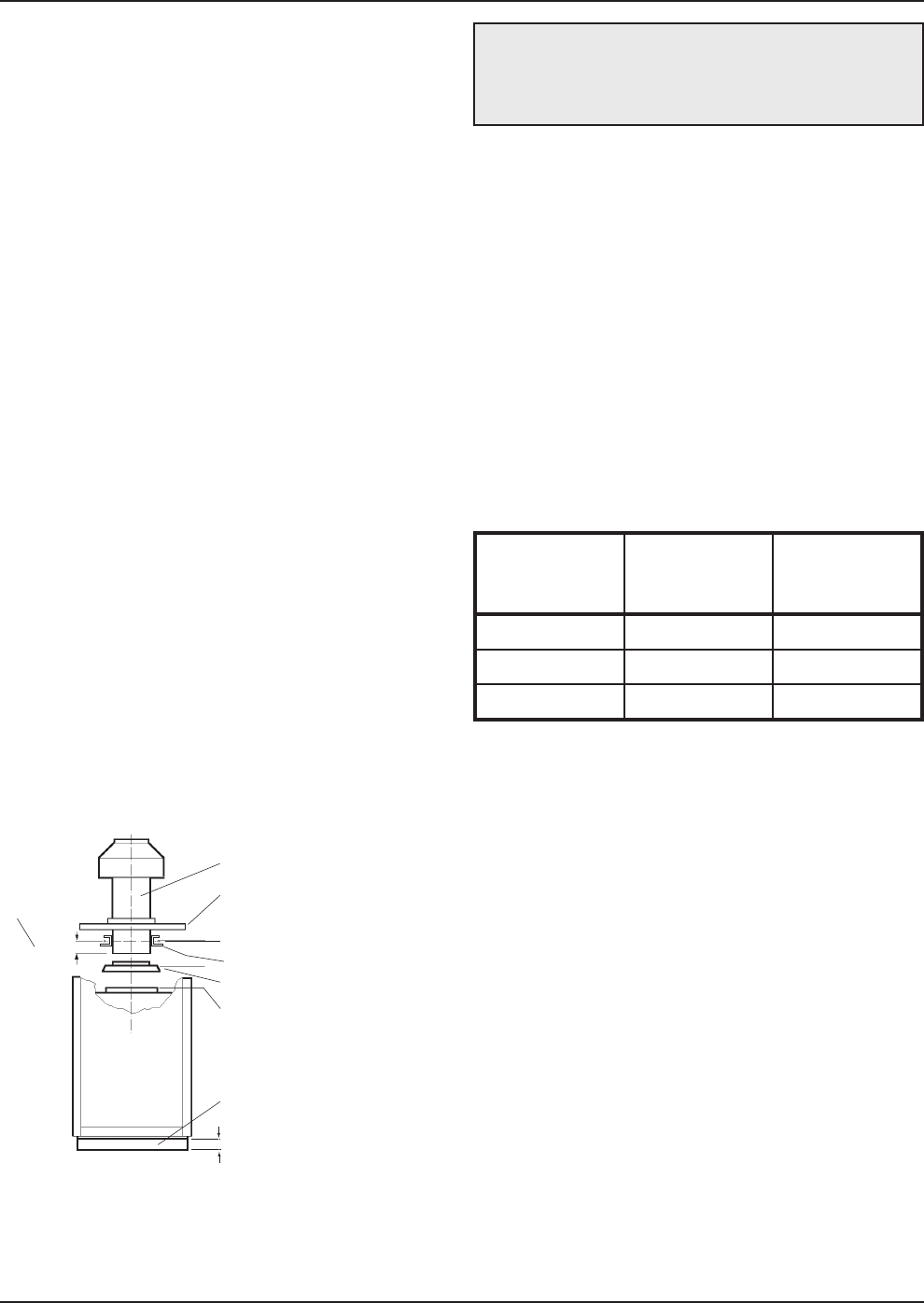

1. Remove the louvered jacket top by removing four

(4) #10 flat head screws.

2. If originally installed, remove "Pagoda" top from

the louvered jacket top.

3. Place the inner stack adapter panel over the flue

collector inside the heater. Make sure the flanged

side of the flue opening is up.

4. Turn the stack (draft hood) up side down and set it

down bottom side up.

5. Turn the jacket top panel (removed in Step 1) up

side down and place it through the stack.

6. Attach the three (3) mounting brackets to the stack

using the screws provided and the holes that are

pre-drilled in the stack. Make sure the brackets are

positioned with the flange near the top side of the

stack (see Fig. 9). Caution must be taken not to

over tighten and strip the screw threads.

7. Turn the assembled stack and jacket top, right

side up. The jacket top will be trapped between the

brackets and the top of the stack. Place the stack

over the inner adapter panel flanged hole and

lower the louvered jacket top panel back into its

original position. Reinstall the four (4) green #10

flat head screws removed in Step 1 above.

2-1/2"

COMBUSTIBLE FLOOR SHIELD

(optional for indoor)

DRAFTHOOD

JACKET TOP PANEL

(part of the heater)

#10 SHEET METAL SCREW (3)

MOUNTING BRACKET (3)

FLUE COLLECTOR

(part of heater)

SCREW HOLE

LOCATION

4-3/4"

INNER STACK ADAPTER PANE

L

Fig. 9: Vent Terminal/Indoor Stack Installation

Vent piping the same size or larger than the draft hood

outlet is recommended, however, when the total vent

height is at least ten (10) feet (draft hood relief open-

ing to vent terminal), the vent pipe size may be

reduced as specified in the National Fuel Gas Code,

ANSI Z 223.1. As much as possible avoid long hori-

zontal runs of vent pipe and too many elbows.

If installation requires horizontal runs, the vent pipe

must have a minimum of 1/4 inch per foot rise and

should be supported at not more than five foot inter-

vals. Plumbers tape, crisscrossed, will serve to space

both horizontal and vertical piping. Maximum vent con-

nector horizontal length shall be 1-1/2 feet (18 inches)

for each inch of connector diameter as shown in Table

F.

Gas vents supported only by the flashing and extend-

ing above the roof more than five feet should be

securely guyed or braced to withstand snow and wind

loads. We recommend use of insulated vent pipe

spacer through the roofs and walls.

For protection against rain or blockage by snow, the

vent pipe must terminate with a listed vent cap which

complies with the local codes or, in the absence of

such codes, to the latest edition of the National Fuel

Gas Code, ANSI Z223.1.

The discharge opening must be a minimum of two feet

vertically from the roof surface and at least two(2) feet

higher than any part of the building within ten (10) feet.

Vent stack shall be at least five (5) feet in vertical

height above the drafthood outlet. The vent cap loca-

tion shall have a minimum clearance of four (4) feet

horizontally from, and in no case above or below,

unless a 4-foot horizontal distance is maintained, from

electric meters, gas meters regulators and relief equip-

ment.

WARNING: Indoor heaters require a drafthood that

must be connected to a vent pipe and properly

vented to the outside. Failure to follow this procedure

can cause fire or fatal carbon monoxide poisoning.

Model No.

Vent

Connector

Diameter (in.)

Max.

Horizontal

Length (ft)

0260/0261 7 12

0330/0331 8 13.5

0400/0401 9 15

Table F: Vent Piping Specifications