9

At the time of removal of an existing heater, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances remain-

ing connected to the common venting system are not in

operation.

(a) Seal any unused openings in the common venting

system.

(b) Visually inspect the venting system for proper size

and horizontal pitch and determine there is no

blockage or restriction, leakage, corrosion and

other deficiencies which could cause an unsafe

condition.

(c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the com-

mon venting system are located and other spaces

of the building. Turn on clothes dryers and any

appliance not connected to the common venting

system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

(d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust tankstat

so appliance will operate continuously.

(e) Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame of a match or candle, or smoke from a

cigarette, cigar or pipe to visually check spillage.

(f) After it has been determined that each appliance

remaining connected to the common venting sys-

tem properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and any other gas burning appliance to

their previous conditions of use.

(g) Any improper operation of the common venting

system should be corrected so the installation

conforms with the latest edition of the National Fuel

Gas Code, ANSI Z 223.1. When resizing any

portion of the common venting system, the com-

mon venting system should be resized to approach

the minimum size as determined using the

appropriate tables in Chapter 10 and in

Appendix G of the National Fuel Gas Code,

ANSI Z 223.1 and CAN/CGA - B149.1 -B149.2.

GAS SUPPLY CONNECTIONS

The inlet gas connection of the heater gas valve is

1/2". Provide an adequate gas piping supply line no

smaller than 1/2", according to the chart below:

Maximum Equivalent Pipe Length (Feet)

1/2" Pipe 3/4" Pipe 1" Pipe 1-1/4" Pipe

MODEL NAT PROP NAT PROP NAT PROP NAT PROP

0090 30 80 125 300 400 - - -

0135 15 40 60 150 200 500 -

0195 - 20 35 70 100 250 400 -

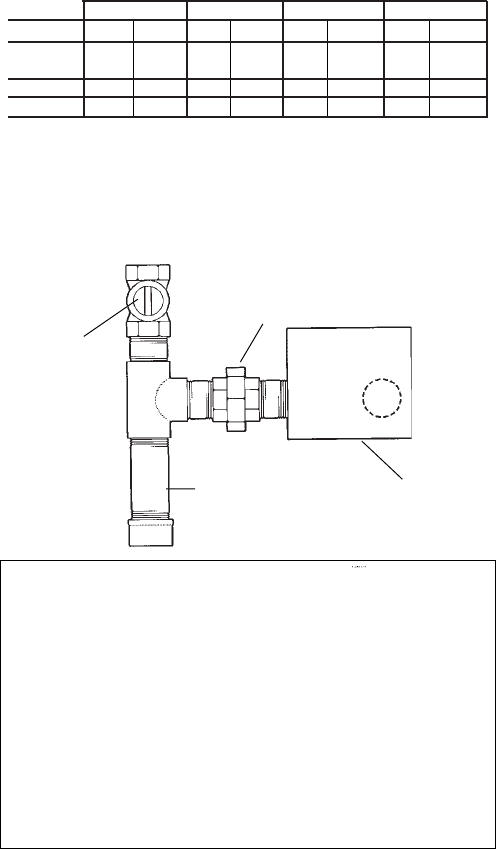

Gas piping must have a sediment trap ahead of the

heater gas controls, and a manual shutoff valve located

outside the jacket. All gas piping should be tested after

installation in accordance with local codes.

CAUTION: The heater and its manual shut off valve must

be disconnected from the gas supply during any pressure

testing of that system at test pressures in excess of 1/

2 psig (3.45 KPA). Dissipate test pressure in the gas

supply line before reconnecting the heater and its manual

shut off valve to gas supply line. FAILURE TO FOLLOW

THIS PROCEDURE MAY DAMAGE THE GAS VALVE.

OVER PRESSURED GAS VALVES ARE NOT COV-

ERED BY WARRANTY. The heater and its gas connec-

tions shall be leak tested before placing the appliance in

operation. Use soapy water for leak test. DO NOT use

open flame.

NOTE: Do not use teflon tape on gas line pipe thread.

A flexible sealant suitable for use with Natural and

Propane gases is recommended.

NOTE: These boilers are also certified to operate on

Propane gas, when equipped with the combination gas

valve and orifices (pilot and main burners) sized for

Propane gas.

GAS PRESSURE-SPECIFICATIONS

Inches W.C. Regulator

Min. Max. Setting

Natural 4.5 10.5 3.5

Propane 12.0 13.0 11.0

Note: Do not exceed maximum inlet gas pressure. The

minimum value shown is for input adjustment.

Sediment Trap Gas Valve

Manual Union

Valve

Fig. # 8192.0