06617645-02

30

MAINTENANCE AND PERIODIC CHECKS

All maintenance and service operations MUST BE CARRIED OUT BY TRAINED PERSONNEL.

Disconnect the electrical supply before undertaking any work on the unit.

(Any servicing performed

when the supply is connected will need a suitable risk assessment).

The compressor casing and discharge line of the compressor are usually hot. Care should be taken

when working in this area. Aluminium coil fins are very sharp and can cause serious wounds. Care

should be taken when working in this area. After any servicing operation ensure that all covers are

replaced and fastened with their locking screws.

It is strongly recommended that regular maintenance checks are performed to maintain correct

operation of the unit:-

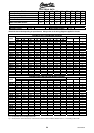

Every three months:

- Check that safety and control devices work correctly as previously described.

- Check all the terminals on the electric board and on the compressor are tight. Periodic cleaning of the

terminals of the contactors should be done: if any damage is found, please replace the contactors.

- Verify refrigerant charge by checking the sight glass.

- Check that there is no oil leakage from the compressor.

- Check that there is no water leakage from the hydraulic system.

- If the unit is to be stopped for a long period, the unit hydraulic circuit, including all internal pipework and

heat exchanger, should be emptied. This operation is compulsory if, during a seasonal shutdown, the

ambient temperature is expected to go below the freezing point of the fluid in the hydraulic circuit (typical

seasonal operation).

- Check hydraulic circuit water level.

- Check the flow switch operation .

- Check the compressor crankcase heater power supply and operation.

- Check defrosting procedure.

- Clean drain pan and pipeline.

- Clean mesh on water strainers.

- Clean the finned coils metallic filters with compressed air. This should be in the opposite direction of the

normal air flow. If filters become fully clogged, clean them with a water jet.

Every six months:

- Check the colour of the sight glass core (green = no moisture, yellow = moisture present).

If it is yellow, the refrigerant circuit should be dehydrated and the refrigerant filter/drier changed.

- Check the unit noise level.

- Check mounting of fan blades and their balancing, check the tension and the wear of the belt.

REFRIGERANT CIRCUIT REPAIR

If the refrigerant circuits need to be evacuated,, all the refrigerant must be recovered using suitable

equipment. The system must be charged with nitrogen, using a gas bottle with a pressure reducing valve,

until 15 bar pressure is reached. Search for leaks with a bubble leak finder. If bubbles appear, discharge

the circuit before repairing by brazing with a suitable braze alloy. Never use oxygen instead of nitrogen:

explosions may occur.