18

PV500-46U 06/12

9 VENTING

9.1 Venting the Power VT Plus “SANI” models:

Power VT Plus models with “SANI” in the model number are designed for operation only with stainless steel venting

listed by UL, ULC, ETL or CSA for Category IV, positive pressure, gas appliance venting. Installation requires a field

supplied stainless steel adapter from the 6-5/8 female economizer outlet to the specific size (six inch minimum) and

model vent used. Follow the vent manufacturer’s instructions for installation, sealing, supporting and terminating

their vent system. Do not use plastic venting of any type on models with SANI in the model number. Do not use a

barometric damper with the Power VT Plus positive pressure vent.

WARNING: On Power VT Plus models with “SANI” in the model number, use only stainless steel venting

listed by a nationally recognized testing laboratory for Category IV, positive pressure, gas appliance

venting. Use of plastic pipe of any type or use of venting materials other than specified in these

instructions can result in failure of the venting system and/or exposure to carbon monoxide which can

result in property damage, personal injury or death.

9.2 Venting the Power VT Plus:

The Power VT Plus (except models with “SANI” in the model number, see above) is designed for operation with a

"positive pressure vent system" constructed of locally obtained 6" or larger schedule 40 or 80 solid CPVC pipe. Do

not use CPVC pipe with cell/foam type construction (such as “CellCore”) or other non-solid CPVC plastic pipe.

Larger solid CPVC pipe may be substituted, however a solid CPVC increaser from 6” to the larger size must be

used for connection to the stainless steel 6-5/8” female flue outlet from the water heater economizer. Do not

insulate the plastic vent pipe. Stainless steel venting listed by UL, ULC, ETL or CSA for Category IV positive

pressure gas appliance venting may be used instead of CPVC plastic pipe venting. If such stainless steel venting is

used, follow the vent manufacturer’s instructions for installation, sealing, supporting and terminating their vent

system. Do not use a barometric damper with the Power VT Plus positive pressure vent.

WARNING: On Power VT Plus, (except models with “SANI” in the model number, see above) use only solid

CPVC pipe or stainless steel venting listed by a nationally recognized testing laboratory for Category IV

positive pressure gas appliance venting. Use of ABS pipe, CPVC pipe, pipe with cell/foam type

construction, plastic vent pipe other than solid CPVC or use of venting materials other than specified in

these instructions can result in failure of the venting system and/or exposure to carbon monoxide which

can result in property damage, personal injury or death.

WARNING: Do not vent this water heater into an existing or traditional gas vent or chimney or combine the

vent with any other appliance. Such venting could result in failure of the venting system and/or exposure to

carbon monoxide which can result in property damage, personal injury or death.

9.3 Maximum Category IV Vent Length (Equivalent Length)

A vertical or horizontal remote Category IV vent system must be used with this appliance. The maximum length of

field supplied Category IV vent is shown in the chart below titled Category IV Vent Equivalent Length.

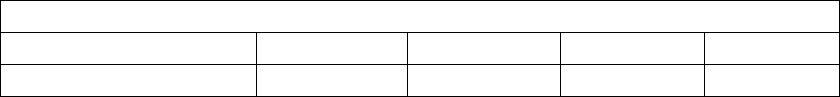

Maximum Category IV Vent Equivalent Length

Vent Size 6” Vent 7” Vent 8” Vent 9” Vent

Max Equivalent Length

100 feet 130 feet 250 feet 450 feet

Pipe fittings reduce the maximum allowable vent length. Use the Category IV vent manufacturer’s equivalent length

deduction for all elbows, terminations, etc. If the information is not readily available from the vent manufacturer, use

the Vent Fitting Equivalent Length chart below to find the total equivalent length for all vent fittings in your

combustion air system. Then subtract this number of feet from the total equivalent length allowed in Maximum

Category IV Vent Equivalent Length chart above. The sum of this calculation is the maximum length of straight vent

allowed. If a longer length is required, repeat the calculation using a larger vent size. When using this chart, no

additional deduction is required for the addition of the vent system terminal.