5

Allow pump suction inlet height to be as close to water

level as possible. Pump will not lift water more than

10' (3m).

Allow use of short, direct suction pipe (To reduce friction

losses).

Allow for gate valves in suction and discharge piping.

Have adequate floor drainage to prevent flooding.

Be protected from excess moisture.

Allow adequate access for servicing pump and piping.

Fire and burn hazard. Modern motors run at

high temperatures. To reduce the risk of fire, do not allow

leaves, debris, or foreign matter to collect around the

pump motor. To avoid burns when handling the motor, let

it cool for 20 minutes before trying to work on it.

NOTICE: When connecting threaded pipe directly to pump,

use Teflon® tape or Plasto-Joint Stik®

to seal connections. Do

not use pipe dope; pipe dope causes cracking in some plas-

tics and may damage components in piping system.

When connecting pipe to pump with union half, use

Teflon® tape or Plasto-Joint Stik® between pipe and union

adapter. Union collar to pump should be assembled dry

and hand-tight.

NOTICE: Pump suction and discharge connections have

molded in thread stops. DO NOT try to screw pipe in be-

yond these stops.

Teflon® Taping Instructions:

Use only new or clean PVC pipe fittings.

Wrap male pipe threads with one to two layers of Teflon®

tape. Cover entire threaded portion of pipe.

Do not overtighten or tighten past thread stop in pump port!

If leaks occur, remove pipe, clean off old tape, rewrap

with one to two additional layers of tape and remake the

connection.

NOTICE: Support all piping connected with pump!

Piping:

Use at least 2" (51mm) pipe. Increase size if a long run is

needed.

To avoid strains on the pump, support both suction and

discharge pipes independently. Place these supports near

the pump.

To avoid a strain left by a gap at the last connection, start

all piping at the pump and run pipe away from the pump.

To avoid airlocking, slope suction pipe slightly upward

toward the pump.

NOTICE: To prevent flooding when removing pump for

service, all flooded suction systems must have gate valves

in suction and discharge pipes.

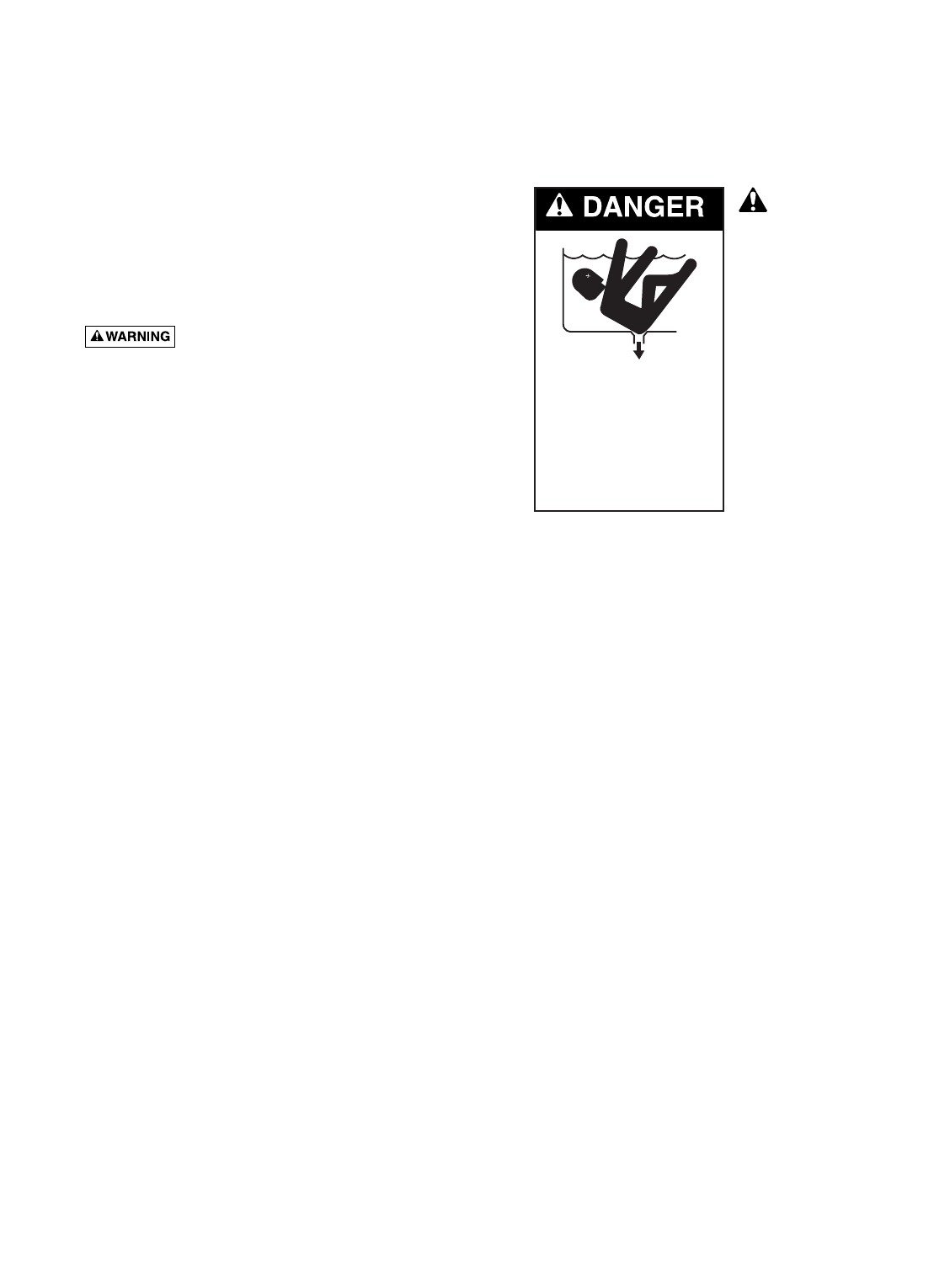

POOL PUMP SUCTION

REQUIREMENTS

Pump suction is haz-

ardous and can trap and

drown or disembowel

bathers. Do not use or oper-

ate swimming pools, spas, or

hot tubs if a suction outlet

cover is missing, broken, or

loose. Follow the guidelines

below for a pump installation

which minimizes risk to users

of pools, spas, and hot tubs.

Entrapment Protection

The pump suction system

must

provide protection

against the hazard of

suction entrapment or hair entrapment/entanglement.

Suction Outlet Covers

All suction outlet covers must be maintained. They must

be replaced if cracked, broken, or missing.

See Page 6 for outlet cover certification requirements.

All suction outlets must have correctly installed, screw-fas-

tened covers in place.

Suction Outlets Per Pump (Figure 3, Page 6)

Provide at least two hydraulically balanced main drains,

with covers, as suction outlets for each circulating pump

suction line. The centers of the main drains (suction outlets)

on any one suction line must be at least three feet apart.

The system must be built so that it cannot operate with

the pump drawing water from only

one

main drain (that

is, there must be at least two main drains connected to

the pump whenever it is running – see Figure 3, Page 6).

However, if two main drains run into a single suction

line, the single suction line may be equipped with a valve

which will shut off

both

main drains from the pump (see

Figure 3).

More than one pump can be connected to a single suc-

tion line as long as the requirements above are met.

Hazardous suction.

Can trap hair or

body parts, causing

severe injury

or death.

Do not block

suction.