11

If shaft seal is worn or damaged, repair as follows:

Pump Dissasembly/Removing Old Seal

Disconnect power to pump motor.

Be

sure valves on suction and return piping are

closed before starting work.

Release all pressure by opening all vents before starting

work.

1.

Drain pump by removing drain plugs on bottom of

pump

body and trap body.

2. Be

sure there is no pressure in trap body; remove

cover

(unscrew by turning counterclockwise).

3.

Remove 6 nuts, lockwashers and flat washers holding

seal

plate to pump body. Pull seal plate and motor

away

from pump body. (You may have to CAREFULLY

use

a screwdriver to separate body from seal plate.)

4.

Remove seven screws and washers holding diffuser to

seal

plate. Remove diffuser.

5.

Remove motor canopy. Being careful not to touch ca-

pacitor

terminals, loosen capacitor clamp and move

capacitor

to one side.

6.

Hold shaft with 7/16" open-end wrench on motor

shaft

flats.

7.

Unscrew impeller from shaft (turn counterclockwise

when

facing it).

NOTICE: On

2 HP model, remove impeller screw

(left

hand thread - turn clockwise) and gasket before

removing

impeller. Inspect gasket for damage,

cracks,

etc. Replace if damaged.

8.

Remove four screws holding seal plate to motor.

9.

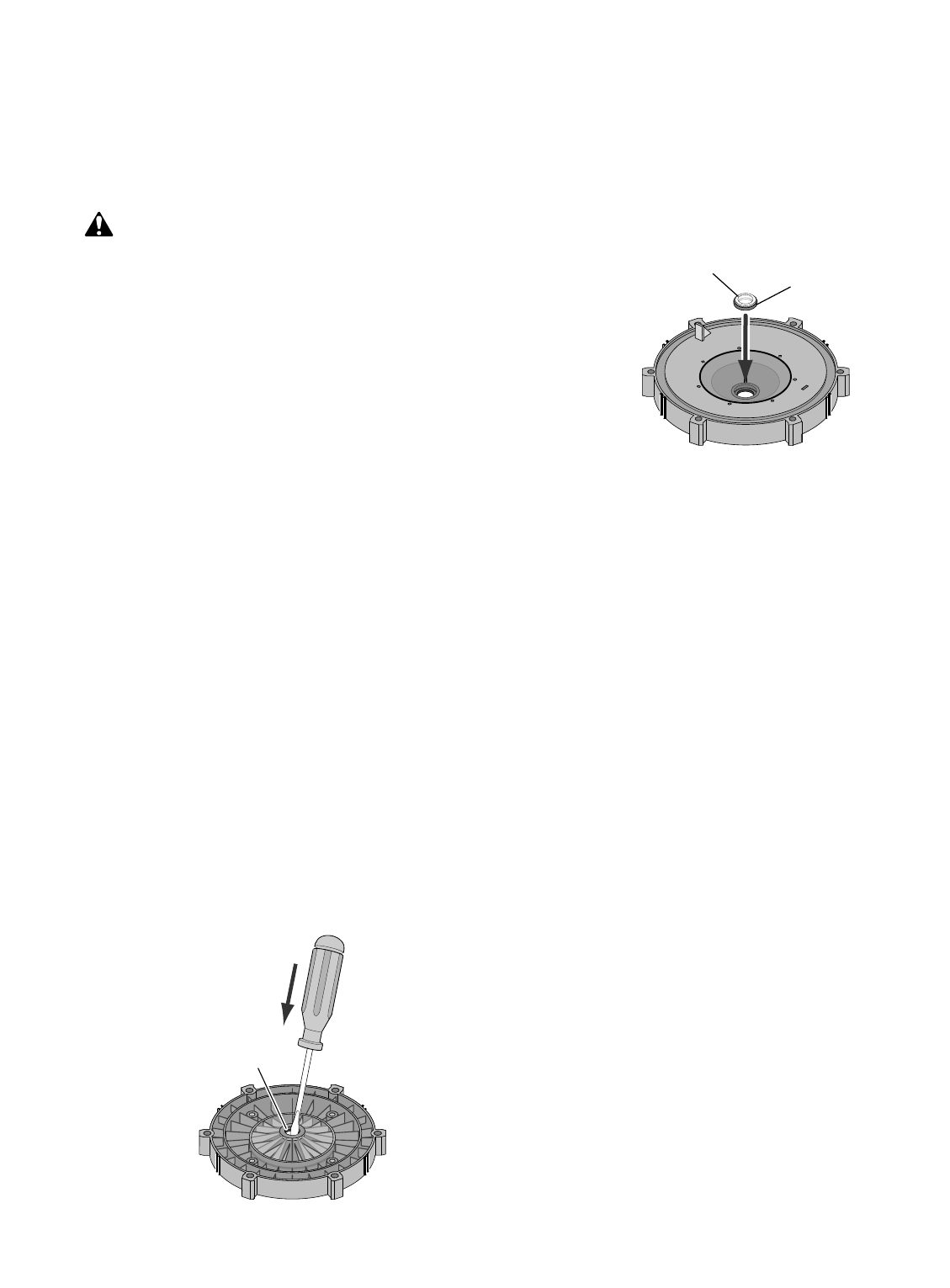

Place seal plate face down on flat surface and tap out

ceramic

seat (Figure 6).

10

. Remove slinger from motor shaft and inspect for dam-

age or abrasion.

11.

Clean seal cavity in seal plate and clean motor shaft.

Pump Reassembly/Installing New Seal

1. Ceramic seat must be clean and free of dirt, grease,

dust,

etc. Wet outer edge with small amount of liquid

detergent;

press ceramic seat into seal plate cavity

firmly

and squarely with finger pressure (Figure 7).

2.

If ceramic seat will not locate properly, remove it,

place face

up on bench and reclean cavity. Ceramic

seat

should now locate.

3.

If seat still will not locate properly, place a cardboard

washer

over the polished face and use a piece of 3/4"

(19mm)

standard pipe for pressing purposes.

NOTICE:

Be sure not to scratch or mar polished sur-

face

or seal will leak.

4.

Replace slinger on end of motor shaft so that impeller

sleeve

will push it into position. If slinger shows signs

of

wear or damage, replace it.

5.

Remount seal plate on motor. Tighten bolts to 60-80

inch-lbs.

(69-92 kg/cm) torque.

6.

Apply a small amount of liquid detergent to inside di-

ameter

of rotating half of seal.

7.

Slide rotating seal member, polished carbon face out,

over

impeller sleeve until rubber drive ring hits back

of

impeller.

NOTICE:

Be sure not to nick or scratch polished seal

face;

seal will leak if face is damaged.

8.

Screw impeller onto shaft (clockwise); this will auto-

matically

locate seal in seal plate.

NOTICE: On

2 and 2-1/2 HP models; install impeller

gasket

and lock screw (left-hand thread - turn coun-

ter

clockwise

). Torque lock screw to 50-55 inch-lbs.

(57.6-63

kg/cm).

9.

Mount diffuser on seal plate; tighten screws to 10-14

inch-lbs.

(11.2-16.1 kg/cm) torque.

10

. Assemble motor and seal plate to pump body with

nuts,

flat washers and lock washers. Torque nuts to

120-130

in-lbs. (138-150 kg/cm).

11.

Prime pump according to instructions on Page 9.

Figure 6

Mechanical seal

ceramic seat

Polished

surface

Rubber

surface

Figure 7