1

20 30 40 50 60 70

2 3

INCHES

mm

2G

2I

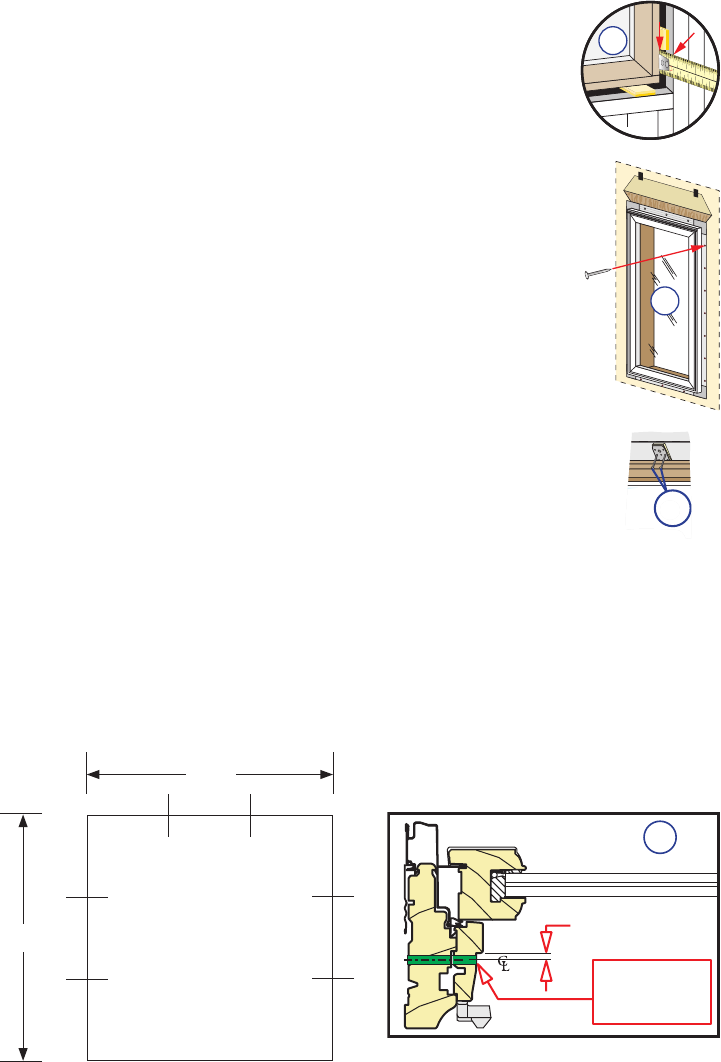

G. Check the interior reveal. Make sure the measurement from the interior

face of the window to the interior face of the wall is equal at several

points around the window.

Note: If the dimensions are not equal, check to make sure the ns are

folded out to 90° at all points.

H. Check window operation (vent units only). Unlock the window by

lifting the lock handle up. Open the window by rotating the crank

handle. Remove the shipping spacers. Open and close the window a few

times to check for proper operation. Close and lock the window.

Note: If there are any problems with the operation of the window,

recheck shim locations and adjust for plumb and square.

I. Fasten the window to opening by driving 2" galvanized roong

nails into each pre-punched hole in the nailing n.

Note: Make sure the n corner is lying as at as possible.

2

SETTING AND FASTENING THE WINDOW (continued)

J. For units with exible non-structural curved n on which clips were

added: Fasten the clips to the opening by driving two #6 x 1-1/2" or longer

corrosion resistant into the pre-punched holes in the clips. If clips are bent

and fastened to the interior stud, install the screws as close to the bend as

possible.

Note: DO NOT shim above the window.

2J

K. For large units with frame height or frame width > 73”; additional frame support screws

must be installed at the head and jambs. On the roomside of the unit, drill 13/64” diameter

clearance holes through the head and jambs at the 1/3 points of the frame.

1/3 1/3 1/3

1/3

1/3

1/3

1/3

1/3

1/3

Screws not required at the sill.

>73"

>73"

2L

3/16"

Max.

Drill 13/64"

clearance hole

through frame

L. On the roomside of the unit, drill 13/64” diameter clearance holes through the head and

jambs at the 1/3 points of the frame.