Interior

2F

2F

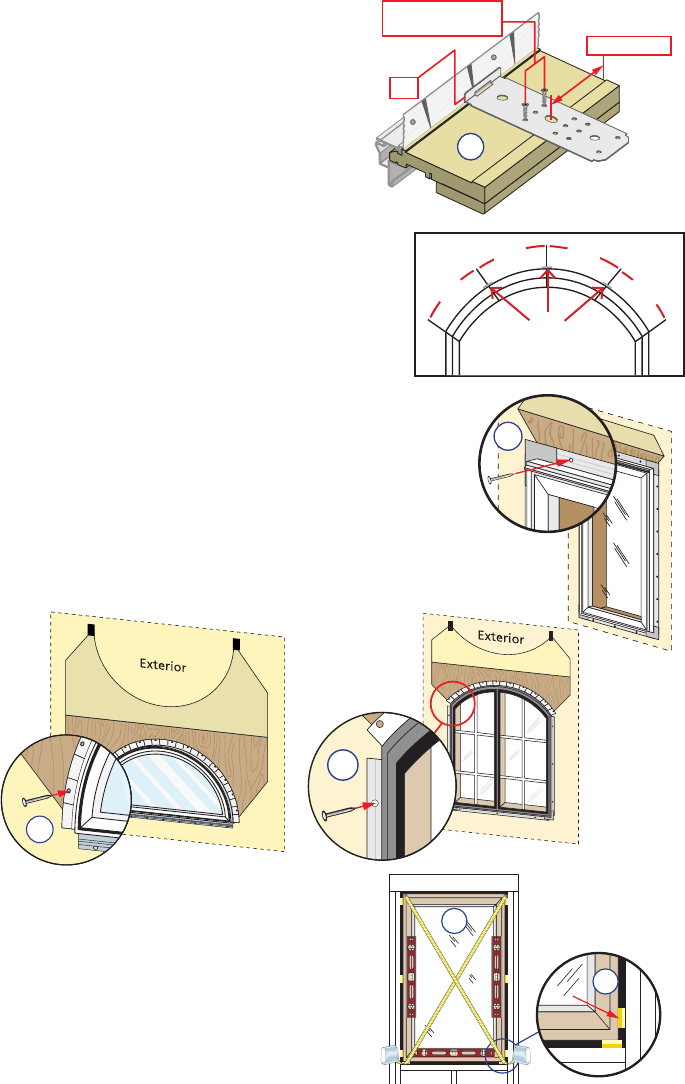

F. Plumb and square window. Place shims 1" from

the bottom and top of the window between the

window and the sides of the opening. Adjust

the shims as required to plumb and square the

window in the opening. If the frame height

exceeds 53", place shims at the midpoint of the

window sides.

Note: Do not shim above the window or in the

space between the spacers at the bottom of the

window. DO NOT over shim.

D. Curved Units with Fins (Continued):

Curved Units with frame radius ≤ 12", full circle

and elipse units will be provided with a exible

non-structural n on the curved portion of the

unit.

Note: is n is intended for ashing only, not as

structural support.

Installation Clips for Structural Support:

Determine installation clip placement. Clips

(provided) should be evenly spaced across the curved

frame member and no more than 16" on center.

Place the clips so the lip is facing up and against the

instillation n. Secure each clip by driving a #6 x 5/8"

corrosion resistant screws through the outer two holes

of the three holes shown.

2E

E. Insert the window from the exterior of the building. Place

the bottom of the window on the spacers at the bottom of the

opening, then tilt the top into position. Center the window

between the sides of the opening to allow clearance for

shimming, and insert one roong nail in the rst hole from

the corner on each end of the top nailing n. ese are used

to hold the window in place while shimming it plumb and

square.

TWO OR MORE PEOPLE WILL BE REQUIRED FOR THE

FOLLOWING STEPS.

2E

2E

2

SETTING AND FASTENING THE WINDOW (continued)

16"

max

16"

max

16"

max

16"

max

Clip

6“ from end

Lip

#6 x 5/8” corrosion

resistant screws

2D