5

Unit Assembly

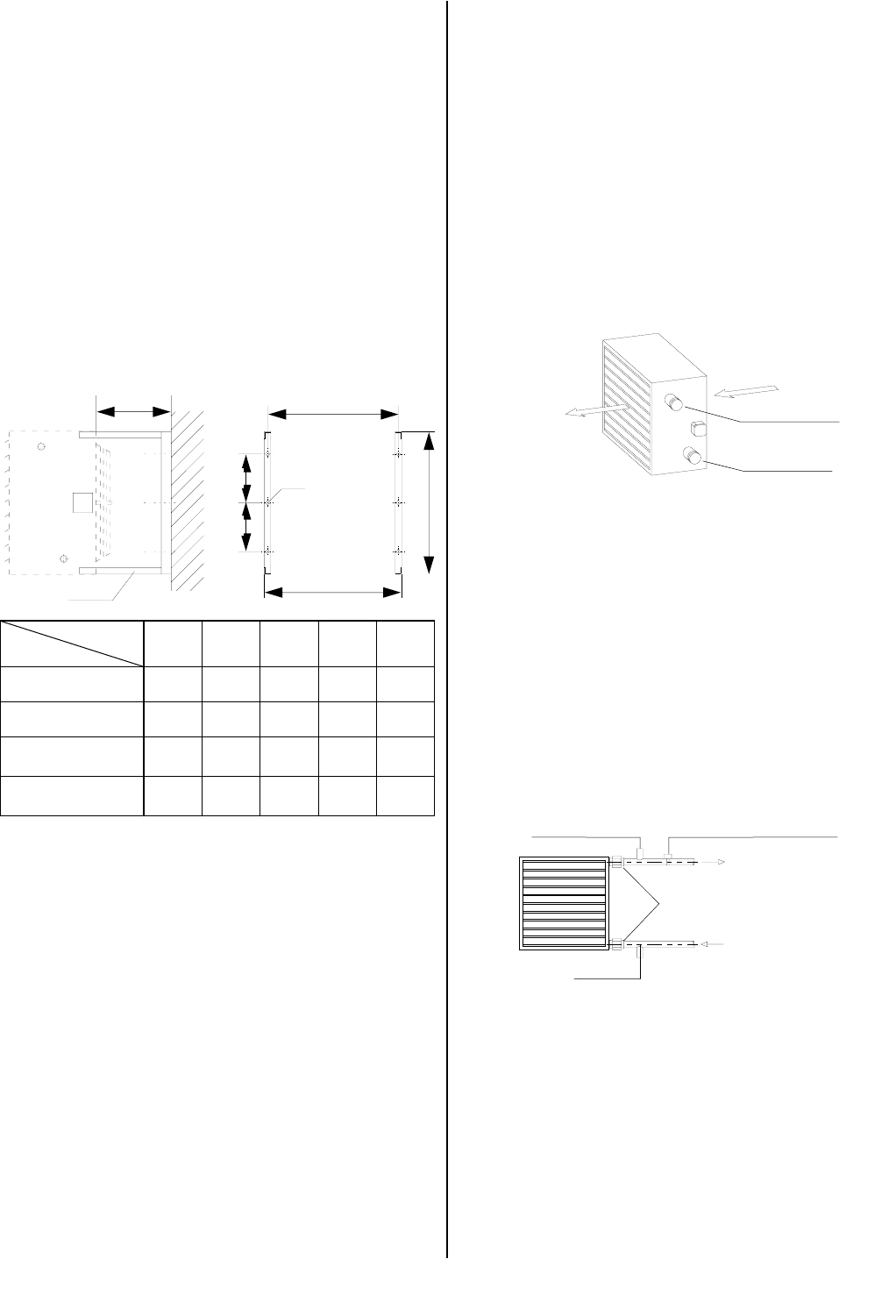

Brackets

Brackets for wall and ceiling assembly (2 per unit) are

inserted into the openings at the back of the unit and at-

tached with the supplied screws.

Components that are attached directly to the units,

such as mixed-air boxes or filter boxes, are equipped

with a bracket adapter.

When using customer-installed bracket constructions,

the minimum distance to the wall (dimension "e") must

be observed!

KO bracket

For wall and ceiling assembly

Cu / Al heat-exchangers

The heat-exchangers are made of copper pipes with alu-

minium plate fins pressed onto the outside. The plate fin

package is surrounded by a galvanized, zinc-plated steel

frame.

The collector and the distributor are made of steel.

Please observe the following for the heat-exchangers:

◊ The heating medium connection is made via

threaded connectors.

◊ The maximum operating temperature is 130 °C.

◊ The maximum operating pressure is 16 bar.

◊ The heat-exchangers are not suitable for operation

with steam or thermal oil.

Connection to the heating system

◊ The REMKO PWW is to be connected by the cus-

tomer via the shut-off valve, automatic air bleeder

and screws in the supply and return lines.

Use compensators if necessary.

◊ It does not matter which side is connected.

Right or left.

◊ The units operate on the principle of counter-current.

◊ The water (supply line) usually comes in at the bot-

tom. The water usually goes out (return line) at the

top.

Draining in case of frost

It is not possible to statically drain the heat-exchanger

completely. The heat-exchanger can only be com-

pletely drained when compressed air is used.

Drainage

Ventilation Frost protection thermostat

Screws

Incoming air

Outgoing air

Incoming water

Outgoing water

PWW

Dimension

a b c d

4030-3 / 4 560 430 510 155 270

4050-3 / 4 640 505 590 192 270

4080-3 / 4 800 620 750 250 270

4100-3 / 4 880 730 830 305 340

e

The brackets must be current-free and screwed on

to the unit and the wall/ceiling.

◊ After assembly, the heat-exchanger must be care-

fully ventilated.

Air pockets in the register reduce the unit perform-

ance.

◊ You can find the thread sizes of the heat register in

the technical data.

When the fan is idle, the heating medium supply

must be interrupted.

Important information about frost protection!

To prevent frost damage, a frost protection mechanism

must be attached for temperatures below 0 °C.

There may not be any water in the heat-exchanger for

systems taken out of operation in rooms susceptible to

frost. The remaining water must be blown out with com-

pressed air.

If this is not possible, the heating medium (water) must

be mixed with a suitable anti-freeze.

No guarantee claims can be made for frost damage

on the heat-exchanger!

KO

e

c

a

b

d

d

Ø12.5