200

EQ-500

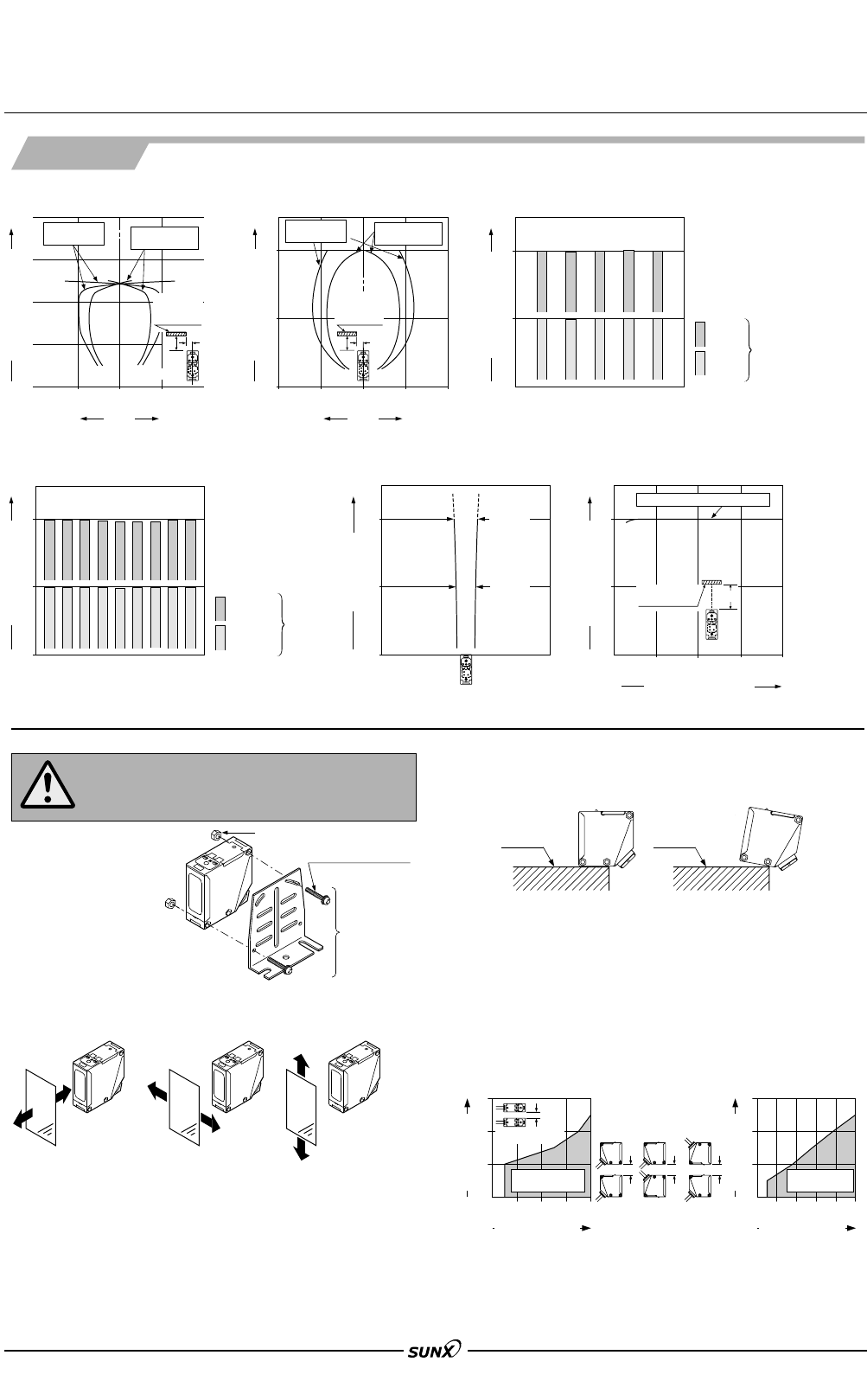

SENSING CHARACTERISTICS (TYPICAL)

Sensing fields

• Setting distance: 0.5 m 1.640 ft

This curve shows

the characteristics

with the maximum

sensing range set

to 1 m 3.281 ft,

with white non-

glossy paper

(200

ן200 mm

7.874

ן7.874 in).

Emitted beam Correlation between sensing object size

and sensing range

0.5

1.640

1

3.281

White non-

glossy paper

Sensor

L

20 10 0 10 20

0

0.5

1.640

1

3.281

L

?

Sensor

EQ-502(T)

EQ-512(T)

• Setting distance: 1 m 3.281 ft

0

0

0.2

0.656

0.4

1.312

0.6

1.969

0.8

2.625

L

?

Black non-glossy paper

Lightness: 5

Black non-glossy paper

Lightness: 5

0

0.5

1.640

1

3.281

Correlation between material

(200

200 mm 7.8747.874 in) and sensing range

These bars indicate the

sensing range with the

respective objects when

the distance adjuster is set

to a sensing range of 1 m

3.281 ft / 0.5 m 1.640 ft

long, respectively, with

white non-glossy paper.

Correlation between color

(200

200 mm 7.874

7.874 in non-glossy paper) and sensing range

These bars indicate the

sensing range with the re-

spective colors when the

distance adjuster is set to a

sensing range of 1 m 3.281 ft

/ 0.5 m 1.640 ft long,

respectively, with white non-

glossy paper.

The sensing range also

varies depending on material.

0.5

1.640

1

3.281

20

0.787

10

0.394

10

0.394

20

0.787

020

0.787

10

0.394

10

0.394

20

0.787

200

ן

200 mm

7.874

ן

7.874 in

Non-glossy paper

200

ן

200 mm

7.874

ן

7.874 in

Non-glossy paper

Sensor

⅐⅐⅐

⅐⅐⅐

⅐⅐⅐

⅐⅐⅐

0

1

3.281

0.5

1.640

Distance L (m ft)

White non-glossy paper

side length a (mm in)

"26 mm

"1.024 in

"20 mm

"0.787 in

White non-

glossy paper

White non-

glossy paper

Left

Right

Center

Operating point ?(mm in)

Left

Right

Center

Operating point ?(mm in)

Setting distance L (m ft)

Setting distance L (m ft)

Sensing range L (m

ft)

Sensing range L (m

ft)

Sensing range L (m

ft)

1 m

3.281 ft

0.5 m

1.640 ft

White non-

glossy paper

Cardboard

Plywood

Black rubber

Black non-grossy

paper (Lightness: 5)

White

Yellow

Orange

Red

Brown

Blue

Green

Gray

(Lightness: 8)

Black

(Lightness: 5)

1 m

3.281 ft

0.5 m

1.640 ft

050

1.969

100

3.937

150

5.906

200

7.874

Setting distance: 1 m 3.281 ft

PRECAUTIONS FOR PROPER USE

Mounting

Sensing object

Sensing object

Do not make the sensor

detect an object in this

direction because it may

cause unstable

Sensing object

Tilt

Interference

prevented area

L mm in

or more

L mm in

or more

L mm in

or more

1

3.281

2

6.562

3

9.843

060

2.362

20

0.787

80

3.15

40

1.575

Mounting interval L (mm in)

Setting distance (m ft)

Setting distance (m ft)

Mounting interval L (mm in)

1

3.281

2

6.562

3

9.843

0

150

5.906

250

9.843

50

1.969

200

7.874

100

3.937

Interference

prevented area

This product is not a safety sensor. Its use is not

intended or designed to protect life and prevent body

injury or property damage from dangerous parts of

machinery. It is a normal object detection sensor.

•

The tightening torque

should be 0.8 N⅐m or

less.

•

Care must be taken regarding the sensor mounting direction with

respect to the object’s direction of movement.

Sensor

mounting

blacket

MS-EQ5-01

(Optional)

M5 nut

M5 (length 30 mm 1.181 in)

screw with washers

•

•

When detecting a specular object (aluminum or copper foil, etc.)

or an object having a glossy surface or coating, please note that

there are cases when the object may not be detected due to a

change in angle, wrinkles on the object surface, etc.

If a specular body is present in the background, faulty operation

may be caused due to a small change in the angle of the

background body. In that case, install the sensor at an inclination

and confirm the operation with the actual sensing object.

•

When a specular body is present below the sensor, use the

sensor by tilting it slightly upwards to avoid faulty operation.

Specular

face

Specular

face

•

•

This product is not easily affected by the reflected light intensity

since this sensor is the adjustable range reflective type. When

the reflected light intensity is remarkably low, the sensing range

may be affected. In that case, mount the sensor, while checking

light-up of the stable indicator (green).

The mounting screws of the terminal cover and display cover

should certainly be tightened to maintain water-resistance; the

tightening torque of the screws should be 0.3 to 0.5 N⅐m.

Automatic interference prevention function

•

When the sensors are mounted closely, use them in the

interference prevented area, as shown below.

•

Note that the detection may be unstable depending on the

mounting conditions or the sensing object to be used.

In the state that this product is mounted, be sure to check the

operation with the actual sensing object to be used.

L mm in

or more

<Correct><Correct><Incorrect>

<

Incorrect><Correct>

08/2005