edwin 02

|

2003

13

2

4

6

8

10

12

14

5,0

4,0

3,0

2,0

1,0

30

25

20

15

10

5

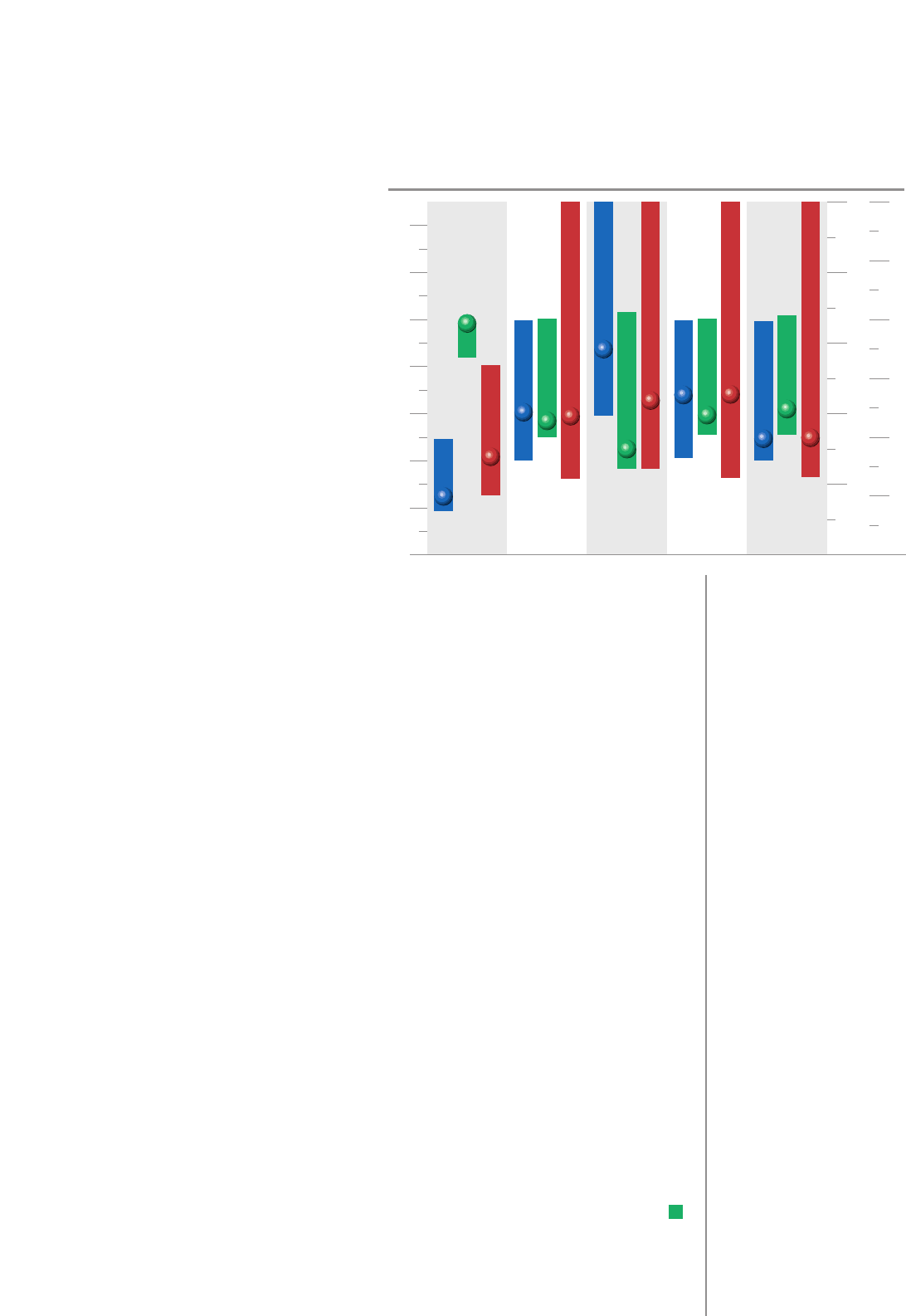

BLUE, GREEN, RED

The blue bars represent the

specific costs of the material.

The bottom end marks the

cost-optimized solution for the

material in question.The blue

ball represents the targeted

concept status.The designer

can thus ascertain the cost of a

particular design.

The green bars stand for

weight. Once again, the ends

of the bars should be regarded

as positive and negative

benchmarks.The green ball

represents the target weight.

The designer can thus ascer-

tain how lightweight a particu-

lar design is.

The absolute costs are shown

in red. Multiplying the above

values produces the range.The

designer can ascertain whether

the cost targets have been

met.

techniques. The reasons are as varied as the

spectrum of alternative materials available:

the often biased expertise of concept engi-

neers regarding the potential, maturity and

cost of alternative materials, semi-finished

products and techniques, the expensive proce-

dures before they are released as suitable for

use, and insufficient importance being attrib-

uted to the learning curve in cost models.

Often dimensional concepts designed for use

with steel are used for lightweight materials;

when transposed at a ratio of 1:1, they gener-

ally result in greatly inadequate weight reduc-

tions. In practice, cost-optimized lightweight

construction fails not least because of a ten-

dency to ignore the designers’ old rule of

thumb that design costs should already be

fixed during the concept phase.

STARTING EARLY

Enter CWO (Cost Weight Optimization) – a

method developed by IVM Automotive that

allows simple calculation of production costs

for lightweight concepts very early on and a

positive impact on the whole process. CWO

enables the marketability of new materials or

semi-finished products to be assessed, new

techniques to be compared, and aims for their

development to be defined. Entire car bodies,

not to mention individual modules or compo-

nents, may be cost-optimized for each size of

production run. By the end of the develop-

ment process you have a vehicle that strikes

the right balance between cost, weight and

other required properties in production, too.

At the heart of the CWO method lies the

simple cost equation

C = m • Cs

Where C is the cost of the component in

euros, m its mass in kilos, and Cs the specific

cost in /kg of the ready-to-fit component:

this includes material and production costs,

tooling cost depreciation and extra charges.

Specific costs are generally determined by

only a handful of cost factors. In a CWO pro-

ject, the designer receives a table of possible

materials matching the project concerned and

the scale of production; the contents of the

table vary considerably depending on the lat-

ter (diagram left).

The aim of the concept phase must be to

achieve the weight targets while maintaining

sufficient rigidity and meeting the cost tar-

gets. In the past, however, the calculation of

production costs has frequently been post-

poned into subsequent project phases. If it is

assumed that automobile designers can opti-

mize and control the mass and other proper-

ties of a vehicle or component using finite

element (FE) methods, CWO represents an

opportunity to optimize costs at the earliest

possible stage while taking account of other

target values (diagram above).

BIG ENLIGHTENMENT

Having developed it between 1996 and 2001,

IVM Automotive has so far applied the CWO

method to various customer projects. The

results are persuasive: in each individual case,

whether involving small or large components,

in small or large production runs, the early

transparency in production costs for light-

weight construction effectively helped opti-

mize costs. In several cases where a maxi-

mum weight saving was achieved, the costs

even matched those of conventional construc-

tion. In one project, for instance, it proved

possible to design the production of a light-

metal car cross member in such a way that its

cost matched that of the reference model

while achieving a 50 percent reduction in

weight. Ralf Anderseck

COST WEIGHT OPTIMIZATION (CWO) DIAGRAM

Sheet steels-

hells

Aluminum,

conventional

Aluminum,

new process

Magnesium,

hot shaped

Aluminum,

IHPF

Specifiic costs (/kg)

Weight (kg)

Total cost ()