17

Table 8. Thermostat Wire Gauge

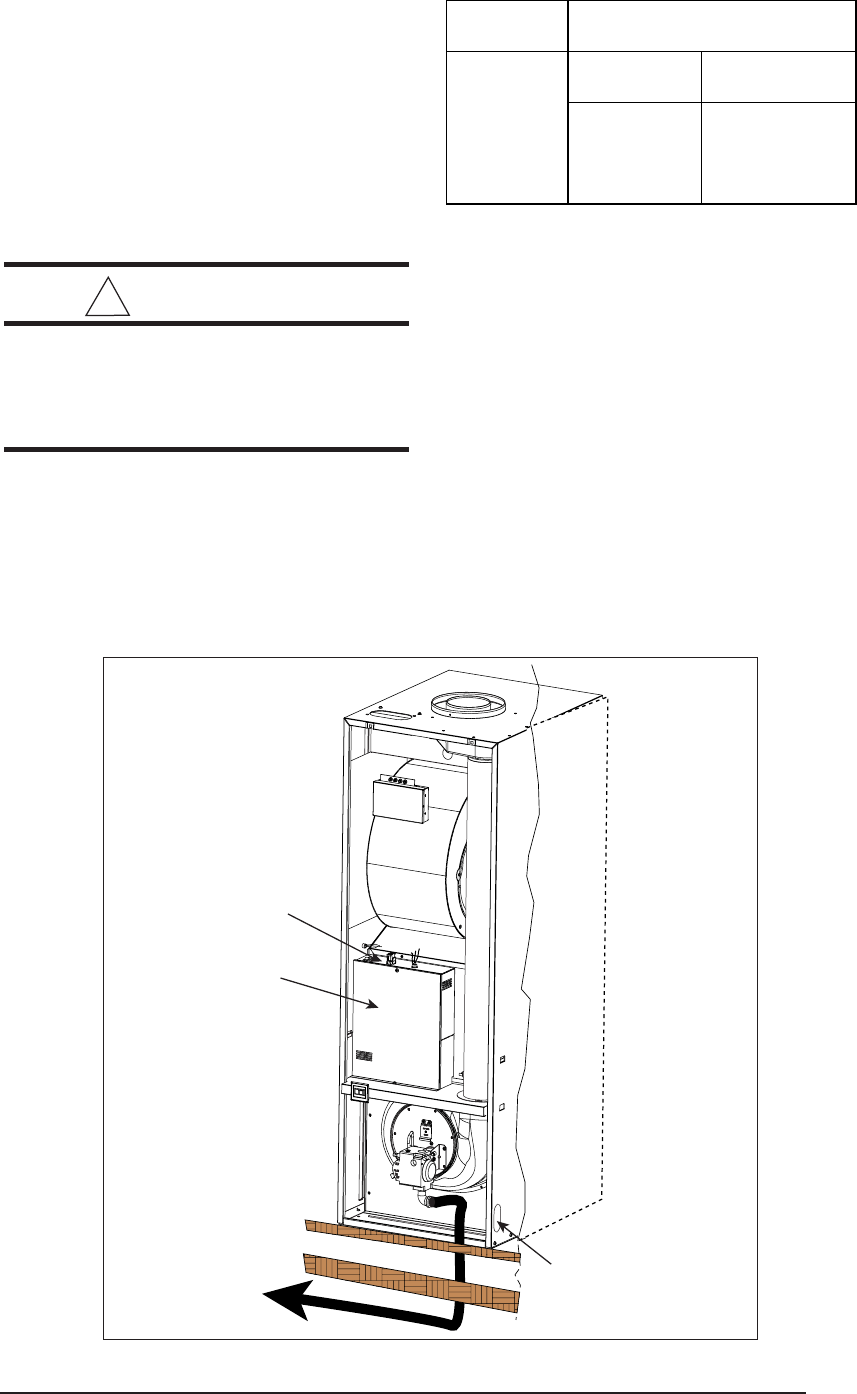

To Gas

Supply

Floor

Control

Panel

On-Off-Fan

Switch

Alt. Fuel

Line Entry

Floor Cavity

Figure 26. Typical Gas Piping

For natural gas operation, the furnace is de-

signed for 7" W.C. inlet pressure. Pressure is

reduced to 3-1/2" W.C. by the pressure regu-

lator in the gas valve. The maximum inlet

pressure for the valve is 13” W.C.

For L.P. gas, pressure to the gas valve must

be more than 11" W.C. but not more than 13"

W.C. Pressure is reduced to 10" W.C. by the

pressure regulator in the gas valve.

!

CAUTION:

The furnace must be converted by a

qualified technician. Improper conver-

sion can cause unsafe operation, ex-

plosion, fire and/or asphyxiation.

Oil Tank and Piping Installation

The following procedures are recommended

as good practice. However, requirements of

local codes and ordinances, H.U.D. Manufac-

tured Home and Safety Standards or National

Fire Protection Association must be satisfied,

where they apply, for an approved installation.

Use a tank capacity suitable for the application

with a weatherproof, capped fill opening and a

shielded vent to let in air as fuel is used. The tank

must be clean inside before filling. All water, rust,

sediment and other foreign matter must be

flushed out.

A fuel or tank gauge is recommended for easy

checking of the fuel level. Check the gauge

reading with a dipstick.

Locate the storage tank conveniently near the

home. For above ground fuel tank installations,

the tank may rest three to four inches off the

T’STAT

Wire Gauge

2-Wire 5-Wire

(Heating) (Heating/Cooling)

24 55 25

22 90 45

20 140 70

18 225 110

Recommended T’STAT Wire

Len

g

th

(

Unit to T’STAT

)