Application Note (Continued)

must be added, one for case to heat-sink (θ

CH

) and one for

heatsink to ambient (θ

HA

). The junction temperature can be

predicted as follows:

T

J

=T

A

+P

D

(θ

JC

+ θ

CH

+ θ

HA

)=T

A

+P

D

θ

JA

T

J

is junction temperature, T

A

is ambient temperature, and

P

D

is the power consumption of the device. Device power

consumption is calculated as follows:

I

IN

=I

L

+I

G

P

D

=(V

IN

−V

OUT

)I

L

+V

IN

I

G

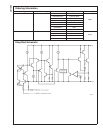

Figure 6 shows the voltages and currents which are present

in the circuit.

Once the devices power is determined, the maximum allow-

able (θ

JA(max)

) is calculated as:

θ

JA(max)

=T

R(max)

/P

D

=T

J(max

−T

A(max)

)/P

D

The LM1085 has different temperature specifications for two

different sections of the IC: the control section and the output

section. The Electrical Characteristics table shows the junc-

tion to case thermal resistances for each of these sections,

while the maximum junction temperatures (T

J(max)

) for each

section is listed in the Absolute Maximum section of the

datasheet. T

J(max)

is 125˚C for the control section, while

T

J(max)

is 150˚C for the output section.

θ

JA(max)

should be calculated separately for each section as

follows:

θ

JA

(max, CONTROL SECTION) = (125˚C - T

A(max)

)/P

D

θ

JA

(max, OUTPUT SECTION) = (150˚C - T

A(max)

)/P

D

The required heat sink is determined by calculating its re-

quired thermal resistance (θ

HA(max)

).

θ

HA(max)

= θ

JA(max)

−(θ

JC

+ θ

CH

)

θ

HA(max)

should also be calculated twice as follows:

θ

HA(max)

= θ

JA

(max, CONTROL SECTION) - (θ

JC

(CON-

TROL SECTION) + θ

CH

)

θ

HA(max)

=θ

JA

(max, OUTPUT SECTION) - (θ

JC

(OUTPUT

SECTION) + θ

CH

)

If thermal compound is used, θ

CH

can be estimated at 0.2

C/W. If the case is soldered to the heat sink, then a θ

CH

can

be estimated as 0 C/W.

After, θ

HA(max)

is calculated for each section, choose the

lower of the two θ

HA(max)

values to determine the appropriate

heat sink.

If PC board copper is going to be used as a heat sink, then

Figure 7 can be used to determine the appropriate area

(size) of copper foil required.

10094716

FIGURE 6. Power Dissipation Diagram

10094764

FIGURE 7. Heat sink thermal Resistance vs Area

LM1085

www.national.com9