W415-0616 / B / 02.18.08

12

GENERAL VENTING

Must be an approved 3" or 4" Diameter Type "L" or "PL" vent,

vented to the outside or connect the vent to a factory built type "A"

chimney using an adaptor; and/or stainless steel chimney liner for

masonry fi replace installations. Use 4" diameter vent if vent or liner

height is over 15' or if installation is over 4,000' above sea level.

Use an approved wall thimble when passing the vent through

walls and a ceiling support/fi re stop spacer when passing the vent

through ceilings (maintain a 3" clearance to any combustibles).

The vent termination must have an approved cap (to prevent water

from entering) or a 45° downturn.

If the termination is located on a windy side of the house, a shield

is recommended to prevent soot from building up on the side of the

house.

Horizontal terminations must protrude 12" from the wall, vertical

terminations require a minimum 24" above the highest point that it

penetrates through the roof.

Depending on pellet quality, vent confi guration and air settings,

black soot may occur on the terminal wall.

TYPE OF VENT

PELLET VENT TERMINATION

VENTING THE PELLET HEATER

MAXIMUM VENTING:

Maximum venting height is 33'. Maximum horizontal offset is 10'.

Use no more than 180° of elbows (two 90' elbows, or two 45'

elbows and one 90' elbow, etc), plus termination.

PELLET VENT MUST MAINTAIN A MINIMUM 3" CLEARANCE

TO ANY COMBUSTIBLE (install vent at clearances specifi ed by

the vent manufacturer).

DO NOT CONNECT THE PELLET VENT TO A VENT OR CHIM-

NEY SERVING ANY OTHER APPLIANCE OR HEATER.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENT-

ING SYSTEM OF THIS UNIT.

INSTALLING THE PELLET VENT

The vent must have a support bracket every 5' when on the exte-

rior wall.

To achieve optimum performance, keep vent runs as short as pos-

sible, especially on horizontal installations.

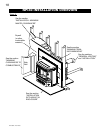

Figure 6

ALCOVE INSTALLATION (NPS40 ONLY)

Minimum Alcove Dimensions

Figure 7

VENT INSTALLATION:

Termination must exhaust above the air inlet elevation, and parallel

or above the exhaust output of the pellet appliance. It is recom-

mended that at least 3' of vertical pipe be installed to create some

natural draft. This is to help prevent the possibility of smoke or

odour during the appliance shut down or in the event of a power

outage.

Horizontal sections must

have a 1/4" rise every 12"

of travel if longer than 3'.

The pellet vent connec-

tions must be sealed with

HI-Temp RTV Silicone and

screwed together with at

least 3 3/8" long stainless

steel screws. Seal each

vent section by injecting

a liberal amount of 500°F

(260°C) RTV silicone

sealant into the gap. We

recommend sealing the

outside of the vent con-

nections to permit easier

access when

servicing.