25

W415-0434 / C / 03.24.05

White / grey film

forms.

Sulphur from fuel is being

deposited on glass, logs or

combustion chamber sur-

faces.

- clean the glass with a gas fireplace glass cleaner. DO NOT CLEAN

GLASS WHEN HOT.

If deposits are not cleaned off regularly, the glass may become

permanently marked.

Carbon is being

deposited on

glass, logs or com-

bustion chamber

surfaces.

Flame is impinging on the

logs or combustion cham-

ber.

- check that the logs are correctly positioned.

- open air shutter to increase the primary air.

- check the input rate: check the manifold pressure and orifice size

as specified by the rating plate values.

- check that the door gasketing is not broken or missing and that the

seal is tight.

- check that both 4" and 7" vent liners are free of holes and well

sealed at all joints.

- check that minimum rise per foot has been adhered to for any

horizontal venting.

Air shutter has become

blocked

- ensure air shutter opening is free of lint or other obstructions.

Pilot goes out when

the gas knob is re-

leased.

The gas valve has

an interlock device

which will not allow

the pilot burner to

be lit until the ther-

mocouple has

cooled. Allow ap-

proximately 60

seconds for the

thermocouple to

cool.

System is not correctly

purged.

- purge the gas line with the glass door open.

Out of propane gas. - fill the tank.

Pilot flame is not large

enough

- turn up the pilot flame.

- gently twist the pilot head to improve the flame pattern around the

thermocouple.

Pilot flame is not engulfing

the thermocouple.

Thermocouple shorting /

faulty.

- loosen and tighten thermocouple.

- clean thermocouple and valve connection.

- replace thermocouple.

- replace valve.

Faulty valve.

- replace.

Main burner flame

is a blue, lazy,

transparent flame.

Blockage in vent. - remove blockage. In really cold conditions, ice buildup may occur

on the terminal and should be removed as required.

Incorrect installation.

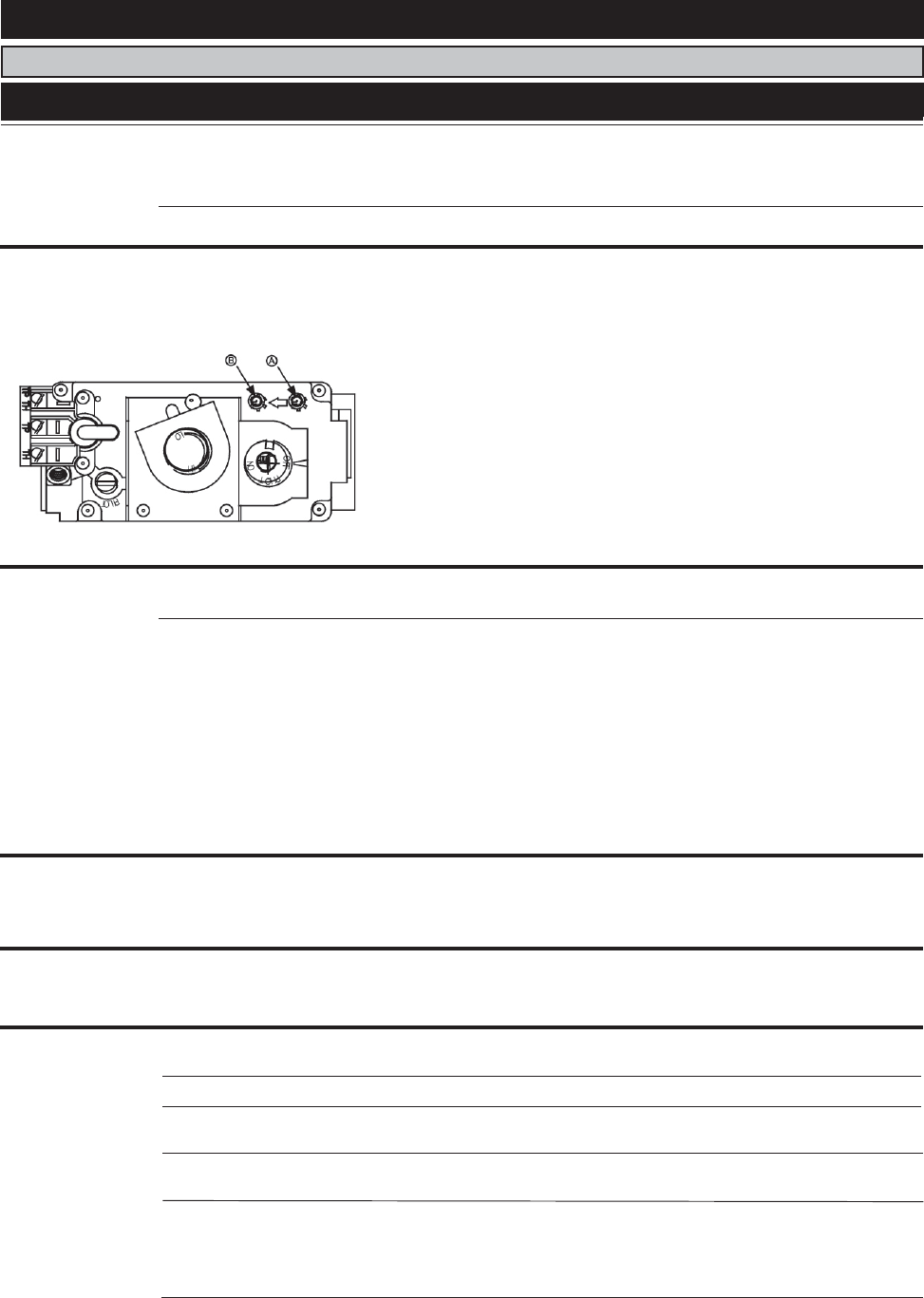

- refer to Figure 13 to ensure correct location of storm collars.

Flames are con-

sistently too large

or too small.

Carboning occurs.

- check pressure readings:

Inlet pressure can be checked by turning screw (A) counter-clock-

wise 2 or 3 turns and then placing pressure gauge tubing over the

test point. Gauge should read 7" (minimum 4.5") water column for

natural gas or 13" (11" minimum) water column for propane. Check

that main burner is operating on "HI".

Outlet pressure can be checked the same as above using screw

(B). Gauge should read 3.5" water column for natural gas or 10"

water column for propane. Check that main burner is operating on

"HI".

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN

SCREWS CLOCKWISE FIRMLY TO RESEAL. DO NOT

OVERTORQUE.

Leak test with a soap and water solution.

Unit is over-fired or under-

fired.

Exhaust fumes

smelled in room,

headaches.

Fireplace is spilling. - check door seal and relief flap seal.

- check for chimney blockage

- check that the paint curing process is complete

TROUBLE SHOOTING GUIDE

SYMPTOM PROBLEM TEST SOLUTION

B

EFORE ATTEMPTING TO TROUBLESHOOT

,

PURGE YOUR UNIT AND INITIALLY LIGHT THE PILOT AND THE MAIN BURNER WITH THE GLASS DOOR OPEN

.