7

W415-0257 / 08.02.01

OPERATING INSTRUCTIONS

WARNING:

Remove all sources of gasoline or other

flammable vapours and liquids in the vicinity of this or

other appliances before lighting.

At this point, the roaring fire that you see when the door is

opened is wastefully drawing heated room air up the chim-

ney -- certainly not desirable. So always operate with the

door fully closed once the medium sized logs have caught

fire.

You can now add larger pieces of wood and operate the

stove normally. Once the stove is entirely hot, it will burn

very efficiently with little smoke from the chimney. There

will be a bed of orange coals in the firebox and secondary

flames flickering just below the top firebrick. You can safely

fill the firebox with wood to the top of the door and will get

best burns if you keep the stove pipe temperatures be-

tween 250 degrees Fahrenheit (120 degrees Celsius) and

450 degrees Fahrenheit (270 degrees Celsius). A surface

thermometer will help regulate this. WITHOUT A STOVE

THERMOMETER YOU ARE WORKING BLINDLY AND

HAVE NO IDEA OF HOW THE STOVE IS OPERATING. A

STOVE THERMOMETER OFFERS A GUIDE TO PERFORM-

ANCE.

Can't get the stove going? Use more kindling and paper.

Assuming the chimney and vent are sized correctly and

there is sufficient combustion air, the lack of sufficiently dry

quantities of small kindling is the problem. Thumb size is

a good gauge for small kindling diameter.

Can't get heat out of the stove? One of two things may have

happened. The stove door may have been closed prema-

turely and the stove itself has not reached optimum tem-

perature. Reopen the door and/or draft control to re-estab-

lish a brisk fire. The other problem may have been wet

wood. The typical symptom is sizzling wood and moisture

being driven from the wood.

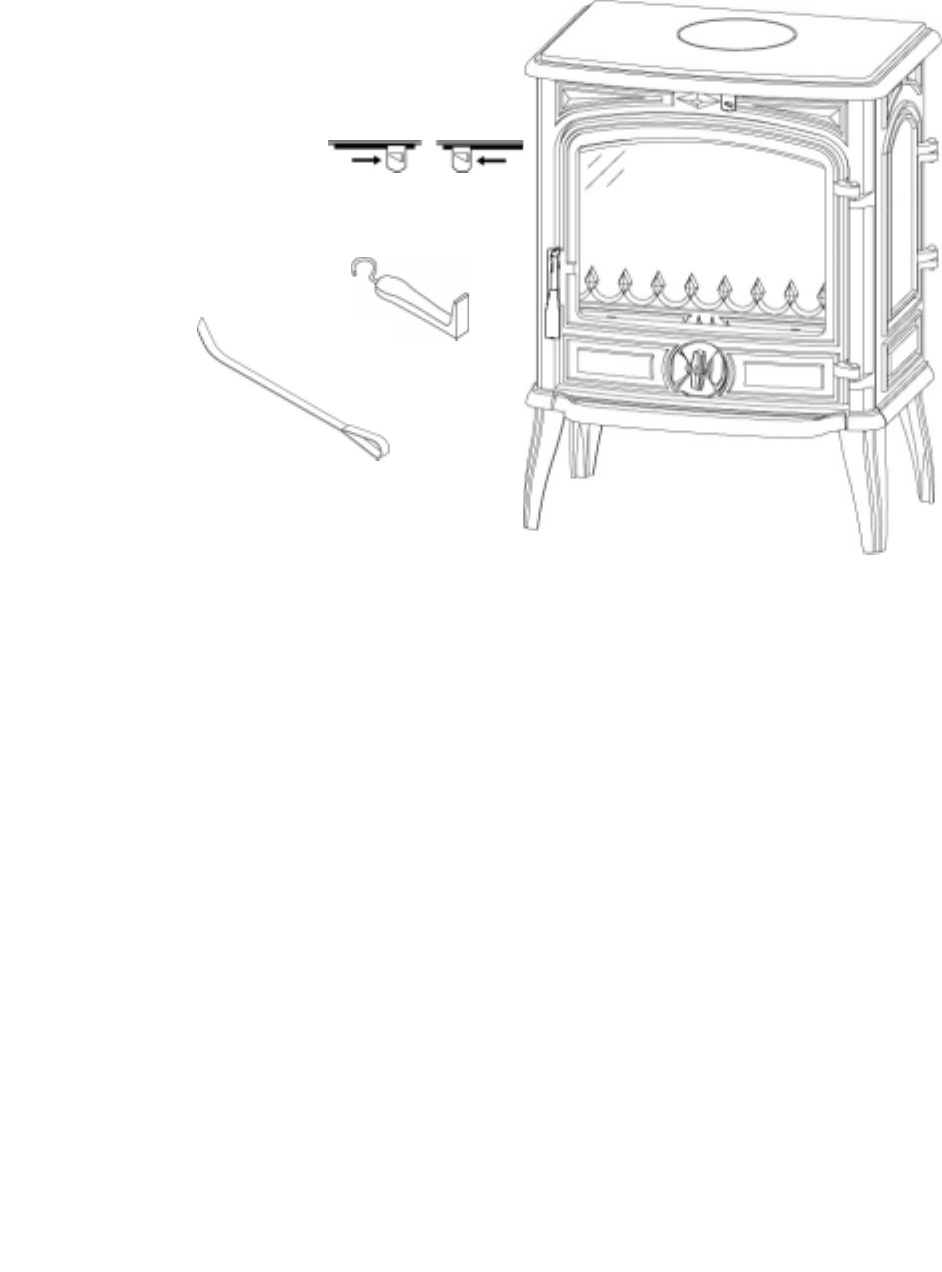

A - DOOR LATCH

B - AIR CONTROL B1: FLAP OPEN

B2: FLAP CLOSED

C - ASH FENDER

D - ANDIRON

E - POKER

F - HAND TOOL

When lit for the first time, the stove will emit a slight

odour for a few hours. This is a normal temporary con-

dition caused by the "burn-in" of internal paints and

lubricants used in the manufacturing process and will

not occur again. Simply open a window to sufficiently

ventilate the room during the first few hours of opera-

tion.

To start, a brisk fire is required. Place loosely crumpled

paper on the grate and cover with dry kindling. Open the air

control fully by moving it to the right. Light the paper and

leave the door slightly ajar (one inch) until all kindling is

burning. To maintain a brisk fire, a hot coal bed must be

established and maintained.

Slowly add larger wood (2x4 size pieces). Lay the pieces

lengthwise from side to side in the hot coal bed with a

shallow trench between, so that the primary air can flow

directly into this trench and ignite the fuel above. When the

fire seems to be at its peak, medium sized logs may be

added. Once these logs have caught fire, carefully close

the door. (Closing the door too quickly after refuelling will

reduce the firebox temperature and result in an unsatis-

factory burn.) Remember it is more efficient to burn me-

dium sized wood, briskly, and refuel frequently than to load

the fireplace with large logs that result in a smouldering,

inefficient fire and dirty glass.

As soon as the door is closed, you will observe a change

in the flame pattern. The flames will get smaller and lazier

because less oxygen is getting into the combustion cham-

ber. The flames, however, are more efficient. The flames

will remain lazy but become larger again as soon as the

castings have been heated thoroughly and the chimney

becomes heated and provides a good draft.

FIGURE 11

B1

B2

F

E

A

B

C

D