MAINTENANCE

If an installed pump (immersed in water) has not been in

operation for a long period of time, check the insulation resistance

and run the pump for 30 minutes every month.

If the pump cannot be run due to lack of water in the tank inspect

the pump and turn the impeller by hand each month and prior

to putting the pump back into service. If insulation drops below

10 megohms, contact an authorized Multiquip service center.

Why perform electrical insulation testing?

Electrical insulation starts to age as soon as it is made. Harsh

environments, especially those with extreme temperature

changes and/or chemical contamination, cause further

deterioration of the insulation (power cord).

As a result, personnel safety (electrocution/shock) and power

reliability can suffer resulting in higher operating cost and

maintenance.

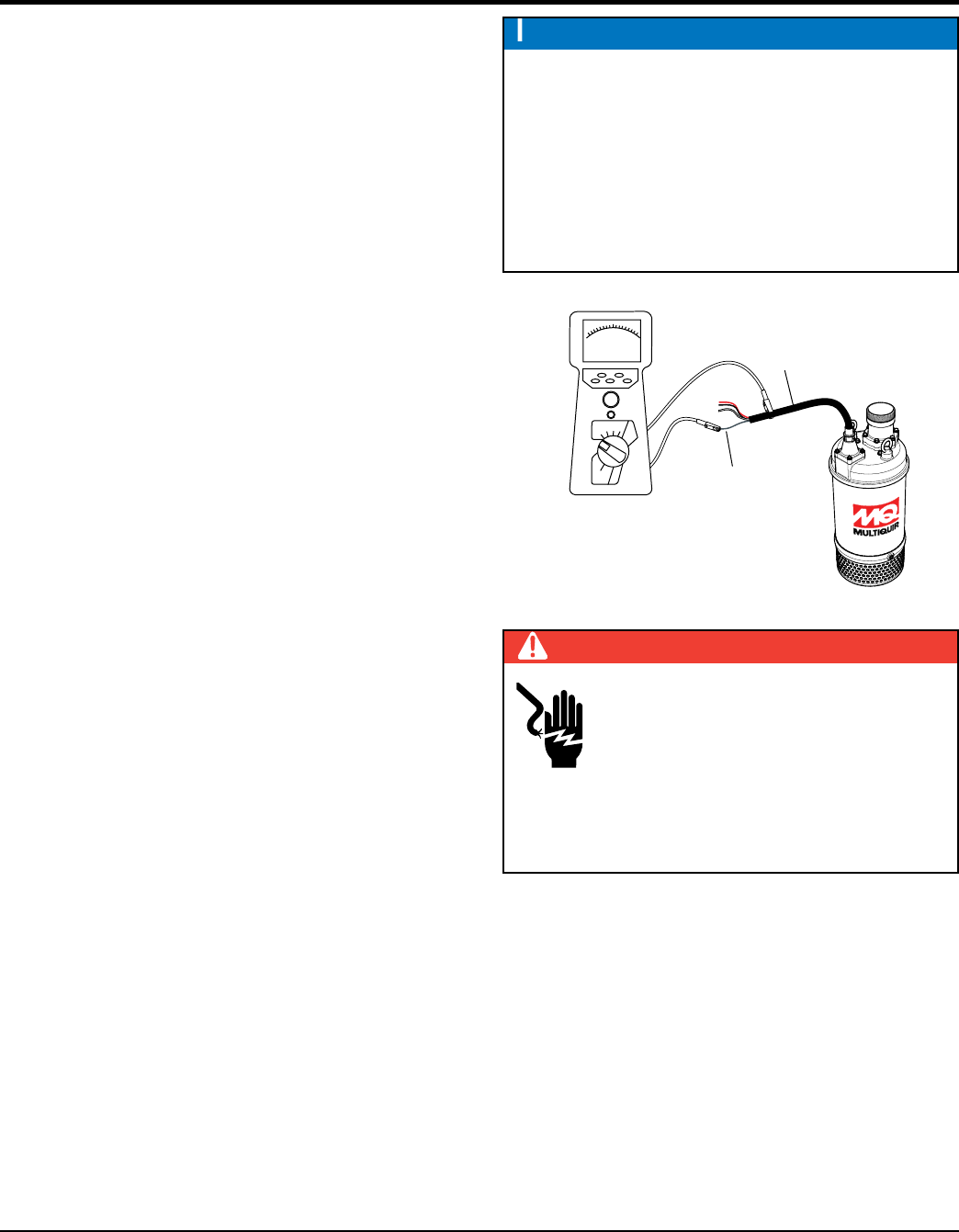

What is Insulation Resistance Testing

Insulation resistance testing applies a regulated stabilized

high voltage (Figure 19), typically 500 VDC or greater across

a dielectric (power cord). Measuring the amount of leakage

current flowing through the dielectric will yield a resistive

measurement in megohms.

Insulating Material Testing

To verify the integrity of the pump's insulating material (power

cable) it will be necessary to perform an electrical insulation test.

Any electrical insulation must have the opposite characteristic

as the conductor: it should resist the flow of current, keeping it

within the conductor.

To measure the IR (current x resistance), the use of an IR tester

must be employed. This IR tester is a portable device that is a

resistance meter (ohmmeter) with a built in DC generator that

develops a high DC voltage.

The high DC voltage from the IR tester is usually 500 VDC or

more. This voltage, when applied causes a small current to flow

through and over the insulation's surfaces. The tester provides

a direct reading of IR in megohms.

A high resistance reading would indicate a "good" insulation,

meaning very little current is escaping through

the insulation.

While a relatively low resistance reading would indicate a

poor insulation, meaning a significant amount of current

may be leaking through and along the insulation.

Figure 19. Insulation Tester Application

1. Area must be free from excessive humidity, corrosive gases,

vapors or vibrations which might damage the pump.

2. Store pump in a vertical position on a pallet or stand.

3. Coil up the cable, and seal the open end (control box

wires) with waterproof tape or a cable cap. This will prevent

moisture from penetrating into the motor which could cause

severe damage to the windings.

4. Give all unpainted surfaces a light coat of oil or grease to

prevent corrosion.

5. If new pumps are stored for more than two months, turn

the impeller by hand every two months to prevent the

mechanical seal faces from seizing up. Failure to do this

may result in seal damage when the pump is started.

NOTICE

Insulation resistance is moisture and temperature

sensitive. When temperature increases, insulation

resistance decreases, and vice versa.

When performing this test measurement, perform the

test using the same test parameters as used in the

initial testing. Contact an authorized Multiquip service

center if the measured cable insulation is 10 megohms

or less.

V

OFF

20M

MEGGER™

SET

UP

M

K

GROUND WIRE

(GREEN)

500 VDCINSULATION

TESTMETER

POWER CABLE

INSULATION

Read and follow the manufacturer's user's

manual prior to operating insulation tester

(megaohm meter). This meter generates

a test voltage of 500 volts or greater. Only

qualified and trained personnel should

use this equipment. The possibility exists of severe

electrical shock, electrocution even death, when

using insulation tester.