MAINTENANCE

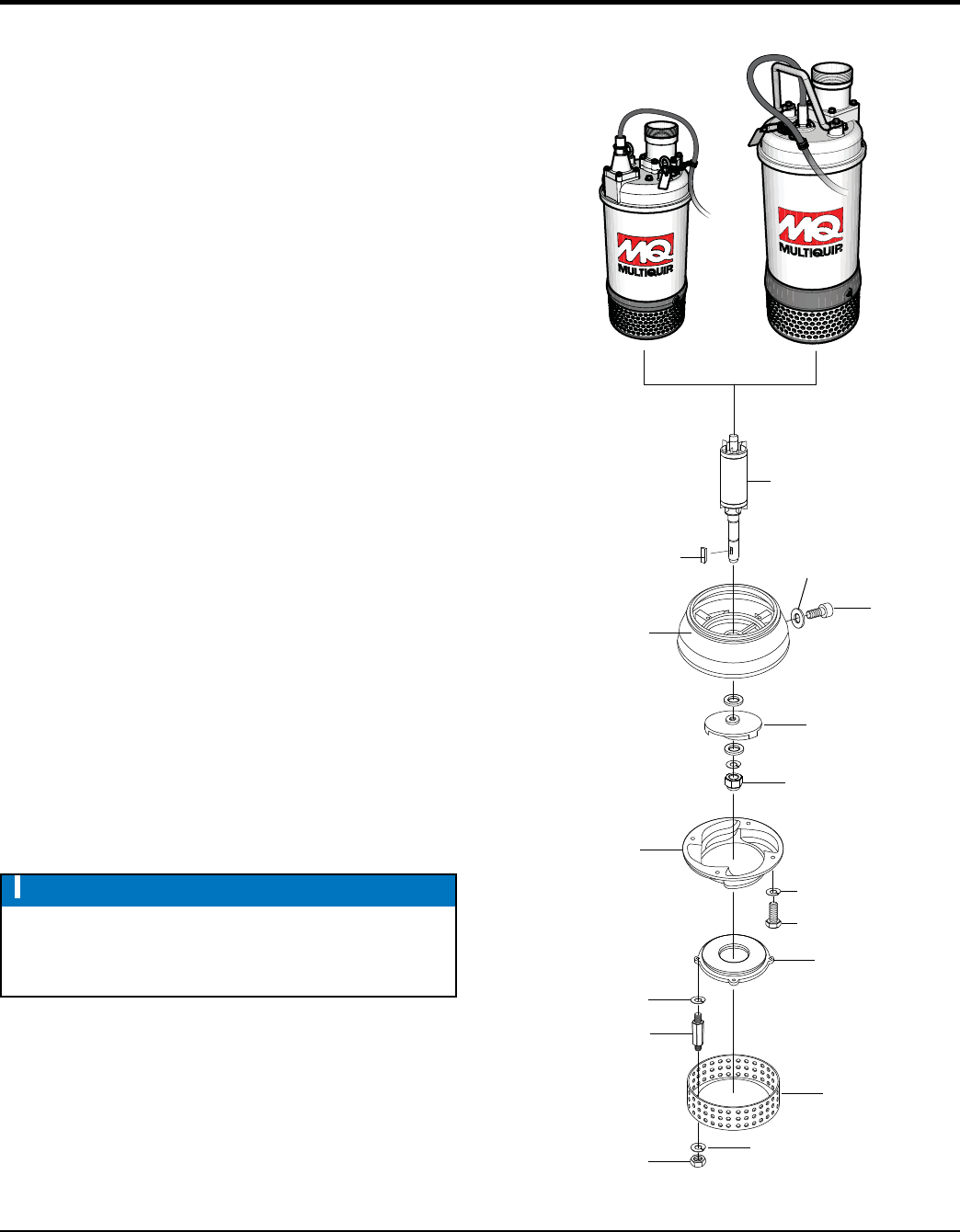

Refer to the the following procedure and Figure 18 for the

removal of the impeller.

1. Remove oil screw and gasket from the oil fill chamber

port. Drain oil from oil chamber as referenced

in Figure 18.

2. Remove the four hex nuts and lock washers that secure

the base plate to the inlet plate.

3. Remove base plate, inlet plate, o-ring and strainer.

4. Next, remove the four bolts and lock washers that

secure pump casing to the seal bracket.

5. Remove pump casing and seal bracket.

6. Remove impeller cap nut and washer from motor shaft.

7. Using a rubber mallot, tap impeller off motor shaft

remove impeller and associated hardware from motor

shaft. If necessary use a puller to remove impeller.

8. Reassemble in reverse order.

1. Clean entire area surrounding mechanical seal.

2. Lubricate mechanical seal with 30 wt. motor oil before

installing back on motor shaft. This lubrication will help

ease the seal back onto the motor shaft.

3. In addition replace o-rings, gaskets and any associated

rubber components that show signs of wear.

4. Inspect and replace if necessary the pump casing

(volute) and seal bracket.

NOTICE

Clearance between impeller and wear plate (pump

casing) should be between .011~.019 in. (0.3~0.5 mm). If

impeller is defective or badly worn, replace immediately.

Figure 18. Impeller Removal

STRAINER

HEX NUT (4)

LOCK WASHER (4)

INLET PLATE

STANDOFF

SCREW

LOCK

WASHER (4)

LOCK

WASHER (4)

PUMP

CASING

IMPELLER

OIL DRAIN

SCREW

GASKET

MOTOR

SHAFT

KEY

CAP NUT

SCREW (4)

ST41230/ST41460

ST61230/ST61460

SEAL

BRACKET