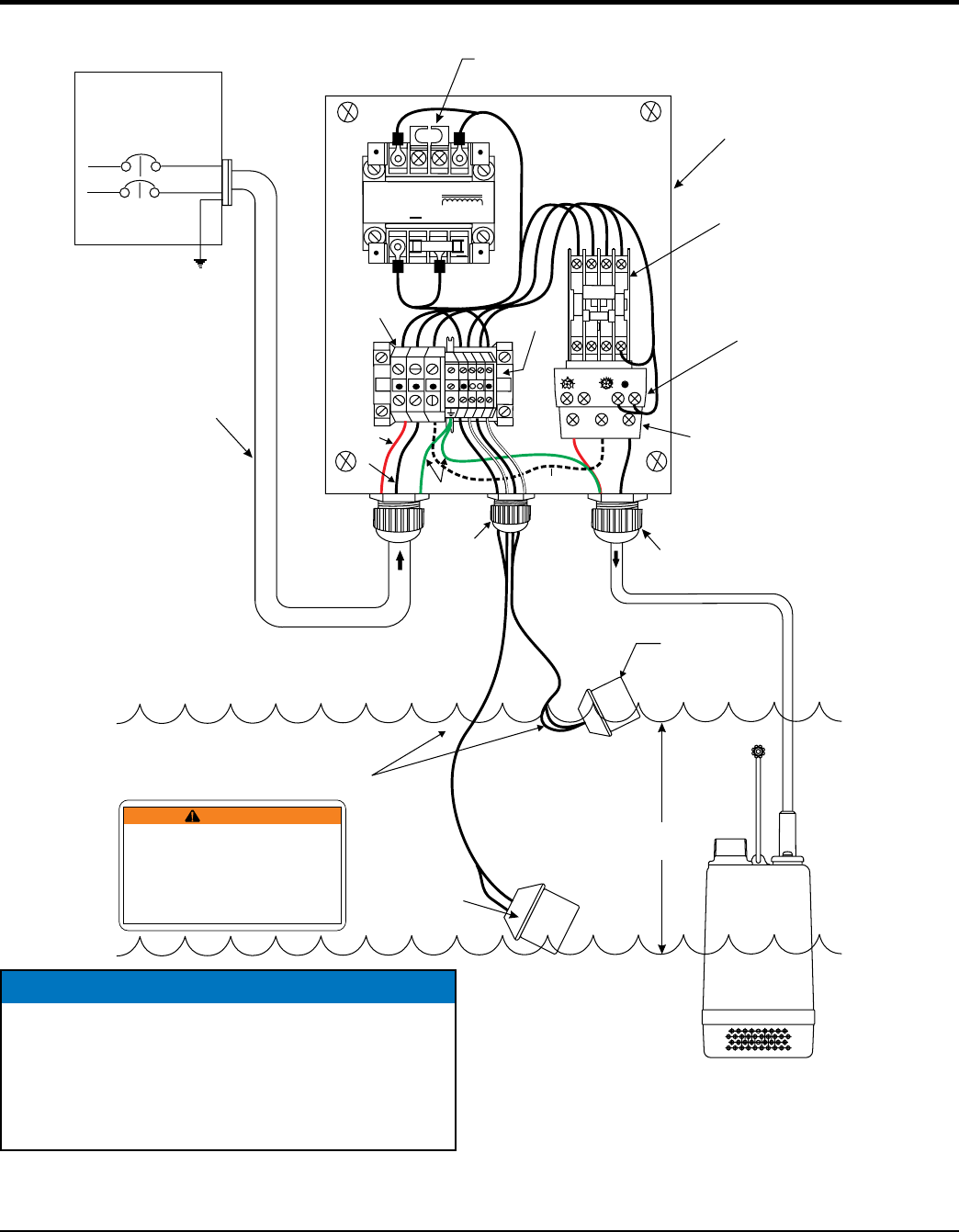

Figure 10. CB200 Control Box (Old Style)

Dual Float Switch Application Diagram

CLASS

AUTO

HAND

30

20

10

30

20

10

FLC(A)

16

12

6.4

7

8

10

STOP

RESET

2

4 6

1 2 3 4

1 2 3 4

FUSE

L1 L2

L3

L1 L2

L3

X2

XF

X1

H4 H2 H3 H1

110

115

120

X1

GREEN

RED

BLACK

EXTERNAL

(230 V )

POWER SOURCE

1Ø

AC

CIRCUIT

BREAKER

RED

BLACK

L1

L2

GREEN

GROUND

SUBMERSIBLE

PUMP

BLACK

RED

START FLOAT

SWITCH. CONNECT

TO TERMINALS 1AND 2

STOP FLOAT

SWITCH. CONNECT

TO TERMINALS 3AND 4

PUMPING

RANGE

SECURE FLOAT SWITCH

WIRES TO PUMP

DISCHARGE HOSE

MOUNT CONTROL

BOX IN AN UPRIGHT

VERTICAL POSITION

AS SHOWN.

FLOAT

SWITCH

INPUTS

FLOATSWITCH

TERMINALBLOCK

ACPOWER

TERMINALBLOCK

ELECTRONIC OVERLOAD

MODULE TERMINAL BLOCK

MTE

CONTACTOR

WARNING

CONTROLBOX INSTALLATION ISTO BE

PERFORMED BYA LICENSEDELECTRICIAN

OR QUALIFIEDPERSONNEL.

THE POSSIBILITYOF ELECTRICALSHOCK

OR ELECTROCUTIONEXISTS, WHICH COULD

CAUSE SEVEREBODILYHARM EVEN DEATH!.

POWER INPUT CABLE

TO CONTROL BOX

POWER INPUT

TO CTRL BX.

TERMINAL BD.

1Ø 230 VAC

POWER OUTPUT

TO PUMP

NOTE:

REFER TO OPERATION MANUAL

FOR THE CORRECT SETTING OF

THE ELECTRONIC OVERLOAD UNI

T.

JUMPER

WIRE

CHECK JUMPER SETTINGS ON

TRANSFORMER, REFERENCE

CB200 WIRING DIAGRAM. 230 VAC

CONFIGURATION SHOWN.

NOTE:

TB1

B

A

B

SINGLE

FLOAT SWITCH

APPLICATION

MODEL SW1WOPA

NOTICE

For correct wiring to pump motor (1Ø, 230 VAC), add

a 16 AWG. jumper wire approximately 5-inches in

length between the input terminal block marked L3 and

terminal 4 on the electronic overload unit. Reference

CB200 wiring diagram (old style)

FLOAT SWITCHES (CONTROL BOX)