GENERAL INFORMATION

The QP305SLT/QPT305SLT centrifugal pump is a high

pressure pump designed to be used for dewatering

applications. The suction port on the QP305SLT/

QPT305SLT uses a 3-inch diameter opening. There are

three discharge ports on the pump, 2 are 1-inch in diameter

and the third is 1.5-inches in diameter. This pump can

discharge water at a rate of approximately 145 gallons/

minute (gpm) or 550 liters/minute (lpm).

Centrifugal or self-priming pumps are designed to purge

air from the suction line and create a partial vacuum in the

pump body. The reduced atmospheric pressure inside the

pump allows water to flow through the suction line and into

the pump body. The centrifugal force created by the rotating

impeller pressurizes the water and expels it from the pump.

Power Plant

This centrifugal pump is powered by an 9.5 HP, air-cooled

4-stroke, single-cylinder HONDA GX340 gasoline engine

that incorporates a low “Oil Alert Feature”.

In the event of low oil or no oil, the HONDA GX340 engine

has a built-in oil alarm engine shutdown feature. If the oil

level is low the engine will automatically shut down.

Standard Centrifugal Pump

Standard centrifugal pumps provide an economical

choice for general purpose dewatering. These types of

pumps should only be used in clear water applications

(agricultural, industrial, residential) as they have a limited

soild handling capability of only 10% by volume.

Suction Lift

This pump is intended to be used for dewatering applications

and is capable of suction lifts up to 25 feet at sea level. For

optimal suction lift performance keep the suction hose or

line as short as possible. In general always place the pump

as close to the water as possible.

Pump Support

The pump should always be placed on solid stationary

ground in a level position.

place the pump on soft soil. The suction hose or

pipe connection should always be checked for tightness

and leaks. A small suction leak in the hose or fittings could

prevent the pump from priming.

Elevation

Higher elevations will effect the performance of the pump.

Due to less atmospheric pressure at higher altitudes,

pumps have the priming ability that they have at

sea level. This is due to the “thinner air” or lack of oxygen

at higher altitudes.

A general rule of thumb is that for every 1,000 feet of

elevation above sea level a pump will lose one foot of

priming ability.

For example, in Flagstaff, Arizona where the elevation is

approximately 7,000 feet, the pump would have a suction

lift of only 18 feet rather than the 25 feet at sea level.

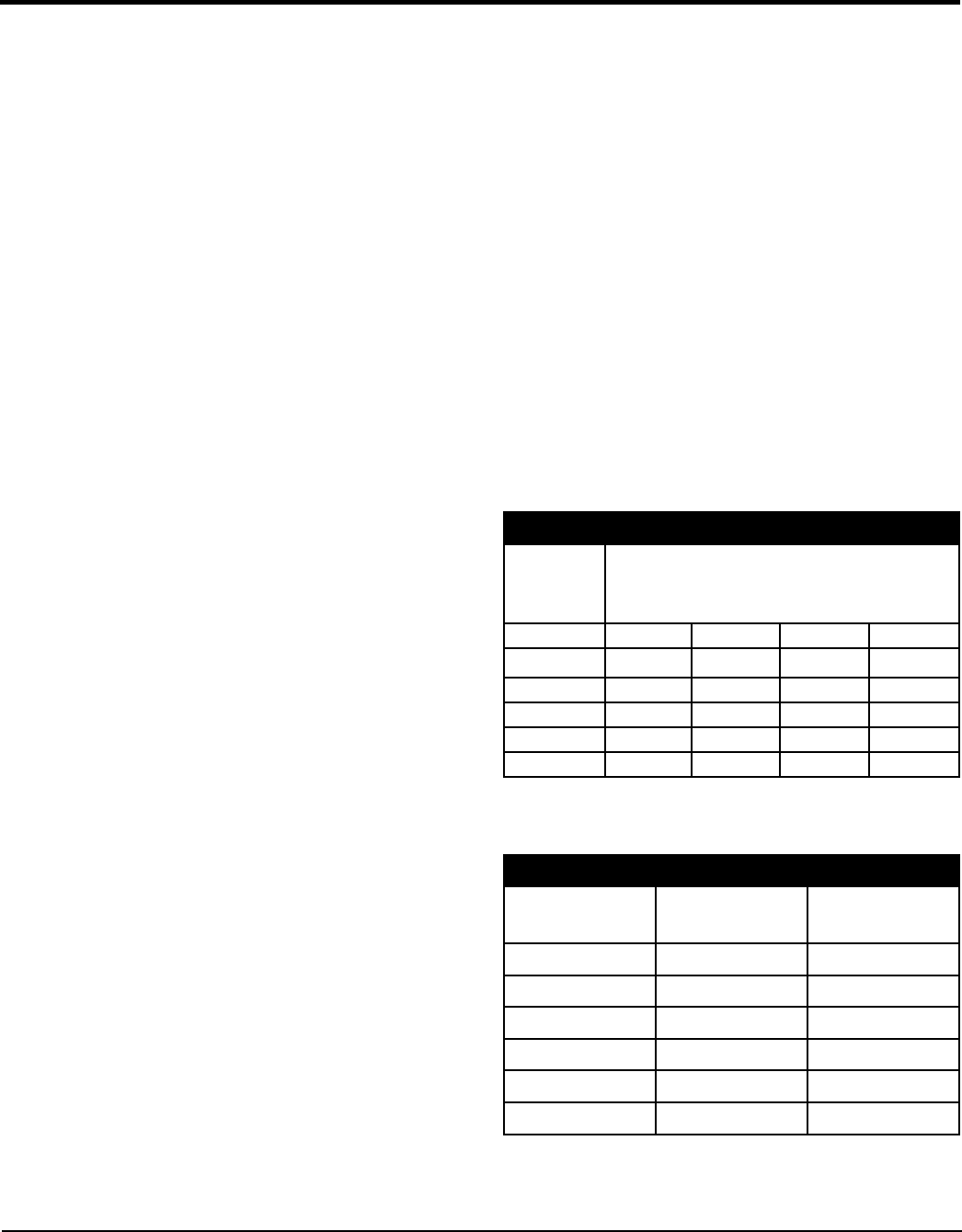

Table 3 shows suction lift at various elevations.

Table 3.

Altitude

Feet

(Meters)

Suction Lift in Feet (Meters)

Sea Level 10.0 (3.048) 15.0 (4.572) 20.0 (6.096) 25.0 (7.620)

2,000 (610) 8.80 (2.680) 13.2 (4.023) 17.6 (5.364) 22.0 (6.705)

4,000 (1,219) 7.80 (2.377) 11.7 (3.566) 15.6 (4.754) 19.5 (5.943)

6,000 (1,829) 6.90 (2.103) 10.4 (3.169) 13.8 (4.206) 17.3 (5.273)

8,000 (2,438) 6.20 (1.889) 9.30 (2.834) 12.4 (3.779) 15.5 (4.724)

10,000 (3,048) 5.70 (1.737) 8.60 (2.621) 11.4 (3.474) 14.3 (4.358)

Table 4 shows percentage drops in performance as

elevation increases.

Table 4.

Altitude

Feet (Meters)

Discharge Flow Discharge Head

Sea Level 100% 100%

2,000 (610) 97% 95%

4,000 (1,219) 95% 91%

6,000 (1,829) 93% 87%

8,000 (2,438) 91% 83%

10,000 (3,048) 88% 78%