MQ-MIKASA MVH-304GHB PLATE COMPACTOR — PARTS & OPERATION MANUAL — REV. #0 (11/25/02) — PAGE 23

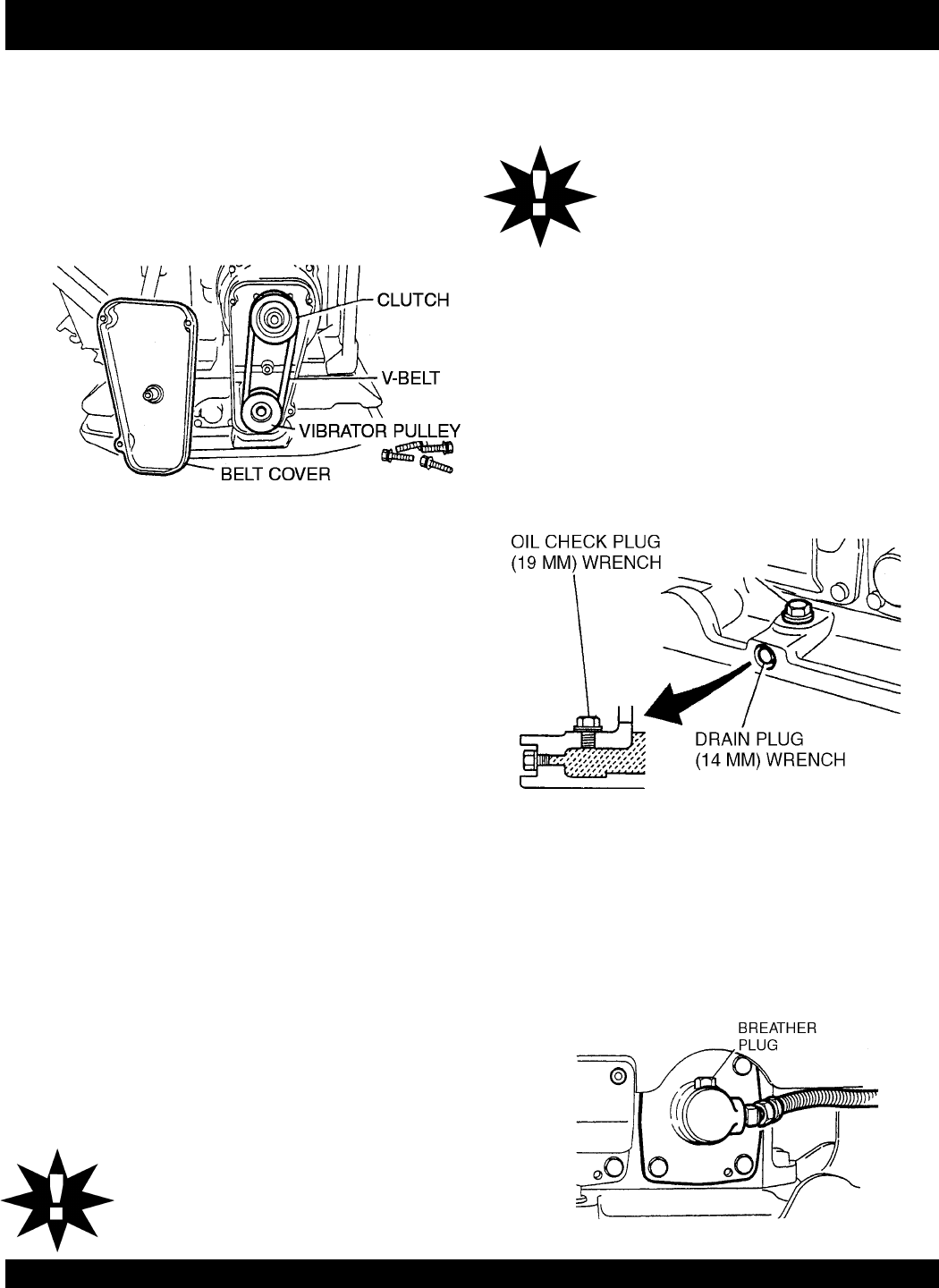

Figure 27 . Vibrator Oil Maintenance

MVH-304GHB—MAINTENANCE

Vibrator Oil Level Check

1. In every 100 hours of operation, with the machine positioned

horizontally, remove vibrator oil level check plug (Figure 27)

off vibrator (19 mm wrench) and see if oil is up to filler port.

Be sure to clean area around check hole to prevent dirt and

dust from entering.

2. In every 300 hours of operation, replace oil (capacity 1,500

cc). For draining oil through level check hole, have the

machine inclined with a sleeper or the like placed under the

compaction plate on opposite side.

* Use engine oil 10W-30 for this lubrication.

Hydraulic Oil

1. Check hydraulic oil in every 100 hours of operation. With

handle bar positioned vertically (storage position), remove

bleeder plug (Figure 28) off the top of hydraulic pump and

check for proper oil level.

2. Replace hydraulic oil after first 200 hours and in every 1,000

hours of operation.

CAUTION:

Always clean the area around the vibrator oil level

check hole before removing oil check plug. This

will prevent dirt and debris from entering the

system.

z

Reinstalling the V-belt

Engage V-belt to lower vibrator pulley and push the V-belt to left

side of upper clutch and, in the same manner as in removal,

rotate offset wrench clockwise so that the V-belt goes back on.

Checking and Replacing the V-Belt and Clutch

1. After 200 hours of operation, remove the belt cover to check

the V-belt tension (Figure 26). Tension is proper if the belt

bends about 10 mm when depressed strongly with finger

between shafts. Loose or worn V-belts reduces power

transmission efficiency, causing weak compaction and

reduces the life of the belt itself.

z

Replacing the V-belt

Remove the belt cover. Engage an offset wrench (19 mm) or the

like to vibrator pulley (lower) fastening bolt. Engage waste cloth

or the like at midway of V-belt on the left side and while pulling it

back strongly, rotate the offset wrench clockwise so that the V-

belt will come off.

z

Checking Clutch

Check the clutch simultaneously with V-belt checking. With belt

cover removed, check outer drum of the clutch for seizure and

"V" groove for wear or damage with your eyes. Clean the "V"

groove as necessary. Wear of lining or shoe should be checked

with running check. If the shoe is worn, power transmission

becomes deficient and slipping will result.

z

Replacing Clutch

Remove V-belt. Remove bolt at engine power output by giving a

shock to an engaged wrench (tapping with hammer or the like)

and rotating bolt counterclockwise. Remove clutch with a pulley

extractor. To reinstall, reverse the procedure.

CAUTION:

Whenever the compactor's vibration becomes

weak or lost during normal operation regardless

of operation hours, check the V-belt and clutch

immediately.

Figure 26. V-Belt Check

Figure 28. Bleeder Plug