PAGE 38 — MAYCO LS400/LS500 PUMP — OPERATION AND PARTS MANUAL — REV. #6 (09/19/11)

BRAKE SYSTEM

The brake system should be periodically checked. Look for

fluid leaks worn or cracked hoses. Check the reservoir for

proper fluid levels. The Atwood surge brake should be

checked for damage. Make sure that all links and pivots are

kept lubricated.

1. Keep all links and pivots lubricated to prevent rusting

and ensure ease of operation. Using SAE 30 oil, lubricate

inside the release handle and inside the actuator body.

This can be reached from the underside of the actuator.

Lubricate the hitch ball with conventional

automotive grease or a lubricant made for

hitch balls.

2. Check for any leaks in the brake system. Periodic checks

should be made on all hoses to guard against cuts and

worn hoses which may cause failure (leaks, rupturing

under pressure, and collapsing). Replace defective hoses.

DO NOT fill the master cylinder reservoir with used

brake fluid. DO NOT fill the reservoir beyond ½" from

top. DO NOT overfill; brake fluid will damage paint.

3. Check the brake fluid level in the master cylinder reservoir.

Keep it filled to within ½" from the top of the reservoir.

4. At the beginning of each year, inspect the brakes for

excessive wear, replace the linings if necessary.

Wheel bearings and seals should be

inspected and packed at this time.

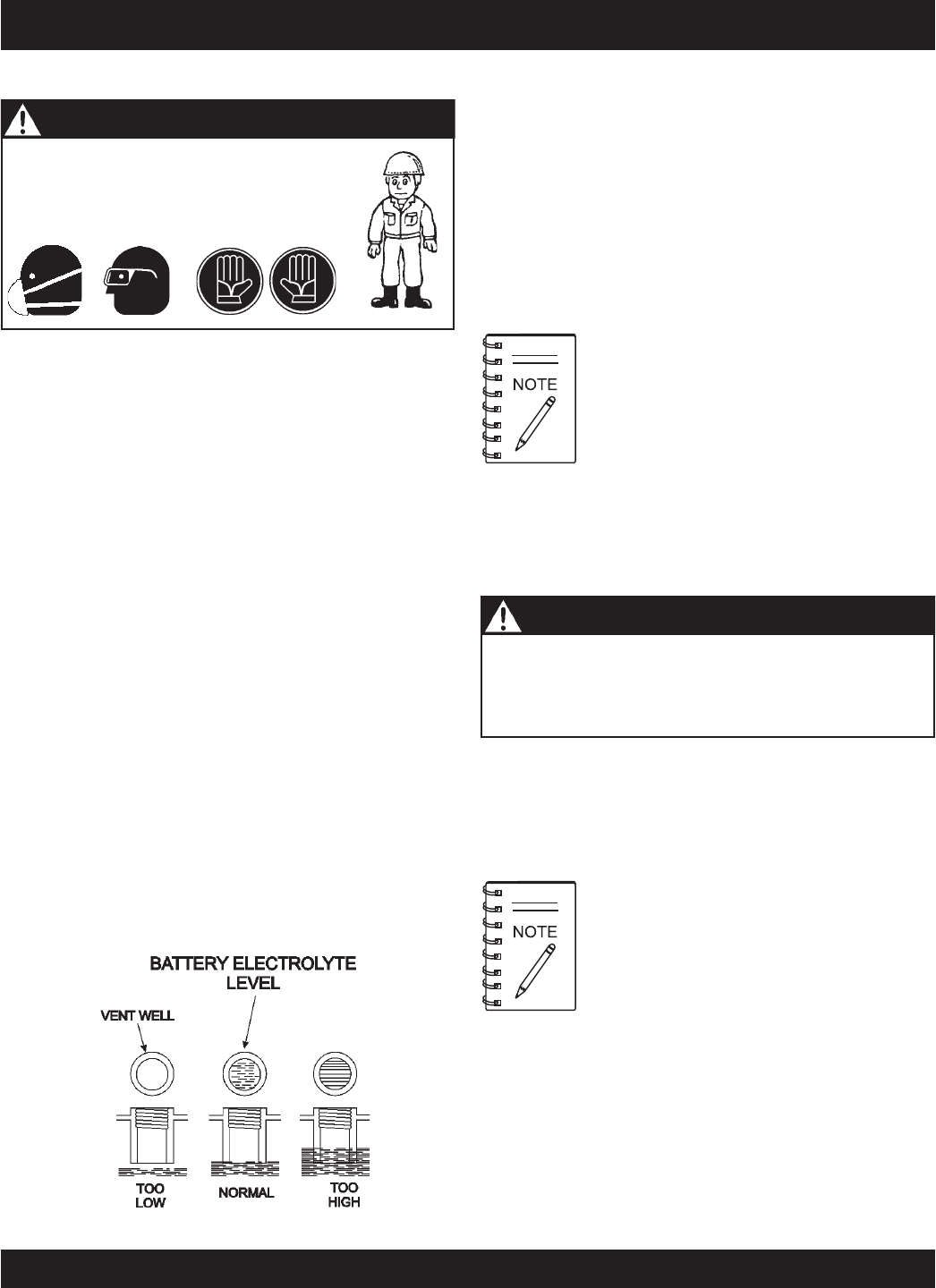

Figure 39. Battery Electrolyte Levels

LS400/LS500 PUMP — MAINTENANCE (PUMP)

Wear

safety glasses

or

face mask

,

protective clothes, and rubber gloves when

working with battery.

CAUTION - BATTERY MAINTENANCE SAFETY

Mishandling of the battery shortens the service life of the

battery and adds to maintenance cost. When handling the

battery do the following:

Be careful not to let the battery electrolyte come in

contact with your body or clothing.

Always wear

eye protection

and

rubber gloves

, since

the battery contains sulfuric acid which burns skin and

eats through clothing.

Always check the battery terminals periodically to

ensure that they are in good condition.

Use wire brush or sand paper to clean the battery

terminals.

Always check battery for cracks or any other damage.

If white pattern appears inside the battery or paste has

accumulated at the bottom, replace the battery.

If the pump will not be in operation for a long period of

time, store in cool dry place and check the battery charge

level every month to maintain the performance of the

battery.

Check the battery regularly and make sure that each

electrolyte level is to the bottom of the vent well

(Figure 39). If necessary add only distilled water in a

well-ventilated area.

CAUTION - MASTER BRAKE CYLINDER

BATTERY MAINTENANCE