PAGE 10 — MAYCO LS400/LS500 PUMP — OPERATION AND PARTS MANUAL — REV. #6 (09/19/11)

LS400/LS500 PUMP — RULES FOR SAFE OPERATION

EMERGENCIES

■

ALWAYS know the location of the

nearest

fire extinguisher

.

■

ALWAYS know the location of the

nearest and

first aid kit

.

■

In emergencies

always

know the location of the

nearest phone or

keep a phone on the job site

.

Also know the phone numbers of the nearest

ambulance

,

doctor

and

fire department

. This

information will be invaluable in the case of an

emergency.

BATTERY

The battery contains acids that can cause injury to the eyes

and skin. To avoid eye irritation,

always

wear safety glasses.

Use well insulated gloves when picking up the battery. Use

the following guidelines when handling the battery:

■■

■■

■

DO NOT drop the battery. There

is the possibility of risk that the

battery may explode.

■■

■■

■

DO NOT expose the battery to

open flames, sparks, cigarettes

etc. The battery contains combustible gases and liquids.

If these gases and liquids come in contact with a flame

or spark, an explosion could occur.

■■

■■

■

ALWAYS keep the battery charged. If the battery is not

charged a buildup of combustible gas will occur.

■■

■■

■

ALWAYS keep battery charging and cables in good

working condition. Repair or replace all worn cables.

■■

■■

■

ALWAYS recharge the battery in an vented air

environment, to avoid risk of a dangerous concentration

of combustible gases.

■■

■■

■

In case the battery liquid (dilute sulfuric acid) comes in

contact with

clothing or skin

, rinse skin or clothing

immediately with plenty of water.

■■

■■

■

In case the battery liquid (dilute sulfuric acid) comes in

contact with your eyes, rinse eyes immediately with

plenty of water, then contact the nearest doctor or hospital,

and seek medical attention.

MAINTENANCE SAFETY

■

NEVER lubricate components or attempt service on a

running pump .

■

ALWAYS allow the pump a proper amount of time to

cool before servicing.

■

Keep the pump in proper running condition.

■

Fix damage to the pump immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor oil, fuel and

fuel filters.

■

DO NOT use plastic containers to dispose of hazardous

waste.

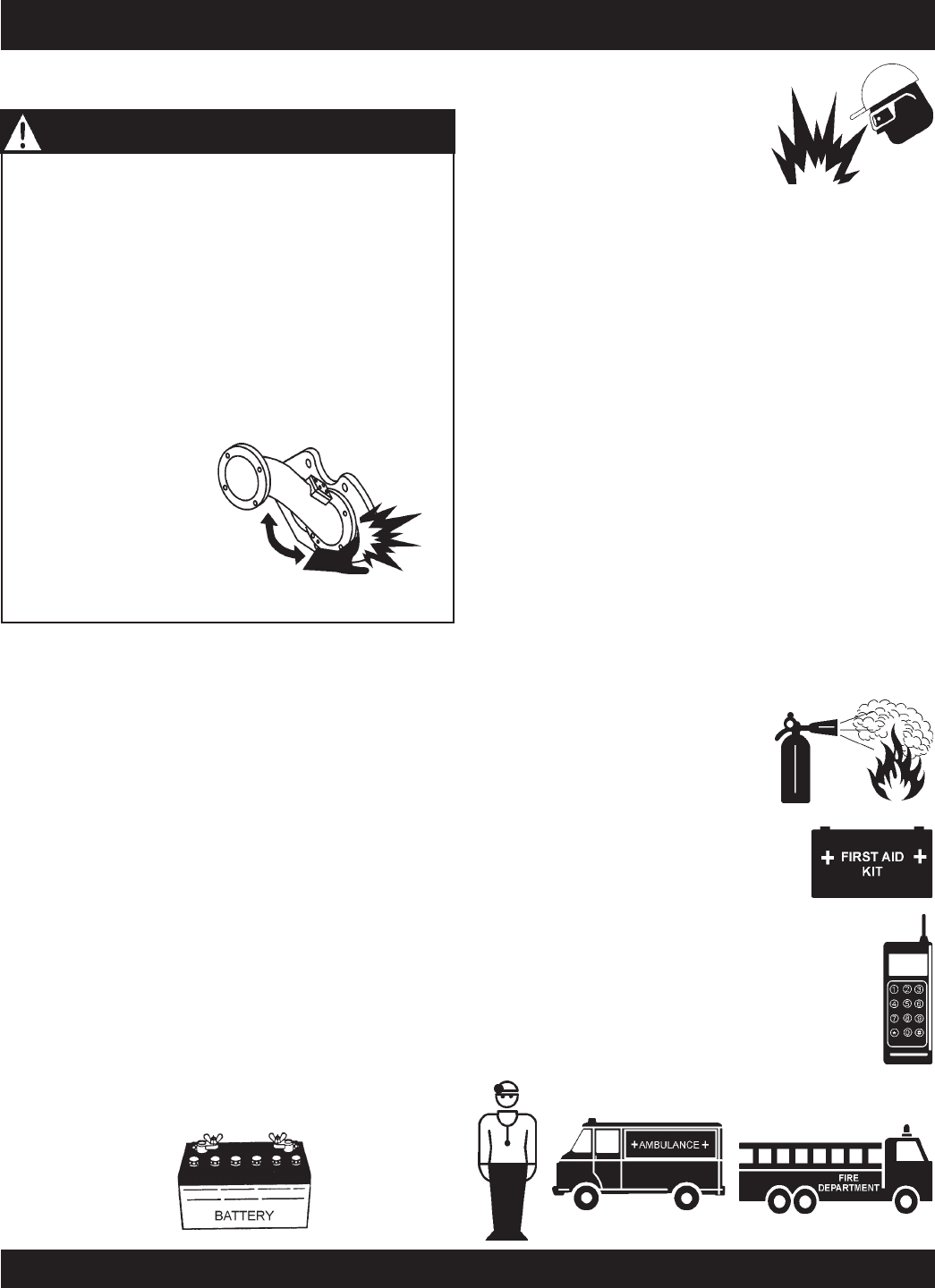

During routine maintenance or removing material

blockage, you will be required to put your hand in the

concrete cylinders or near the shuttle tube. You are at

EXTREME RISK

of injury or

AMPUTATION

if the

engine is running or if pressure is in the hydraulic

system.

Prior to performing any maintenance on the pump,

follow described lock out-tag out procedures. Stop the

engine by turning off the ignition switch and remove

the starter key. Place a “DO NOT OPERATE” tag

over the switch and disconnect the battery. The

pressure reading on the

accumulator pressure

gauge

MUST

read

ZERO. ALWAYS make

sure the accumulator

circuit pressure reads

zero prior to performing any maintenance on the pump.

DANGER - AMPUTATION RISK